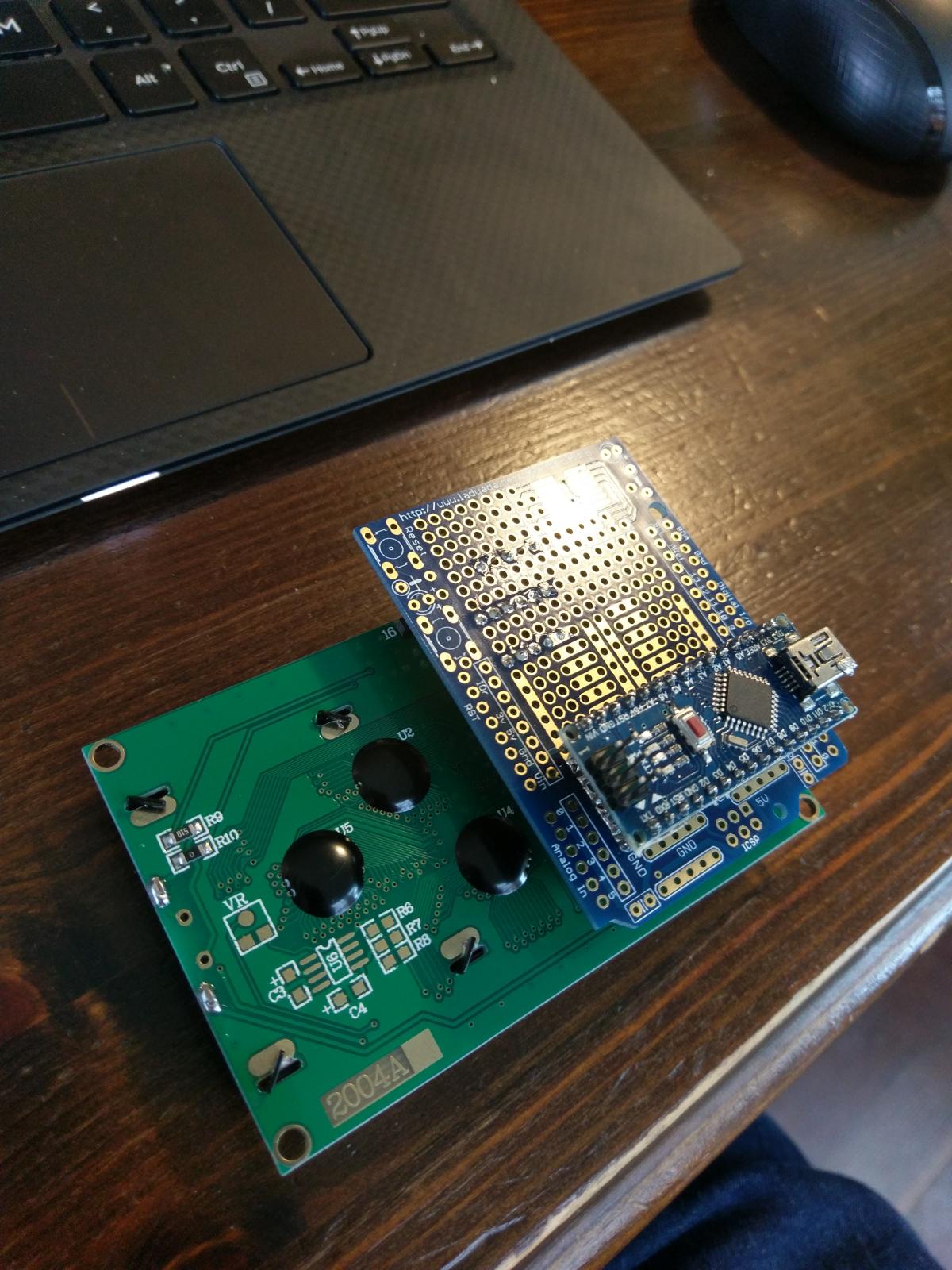

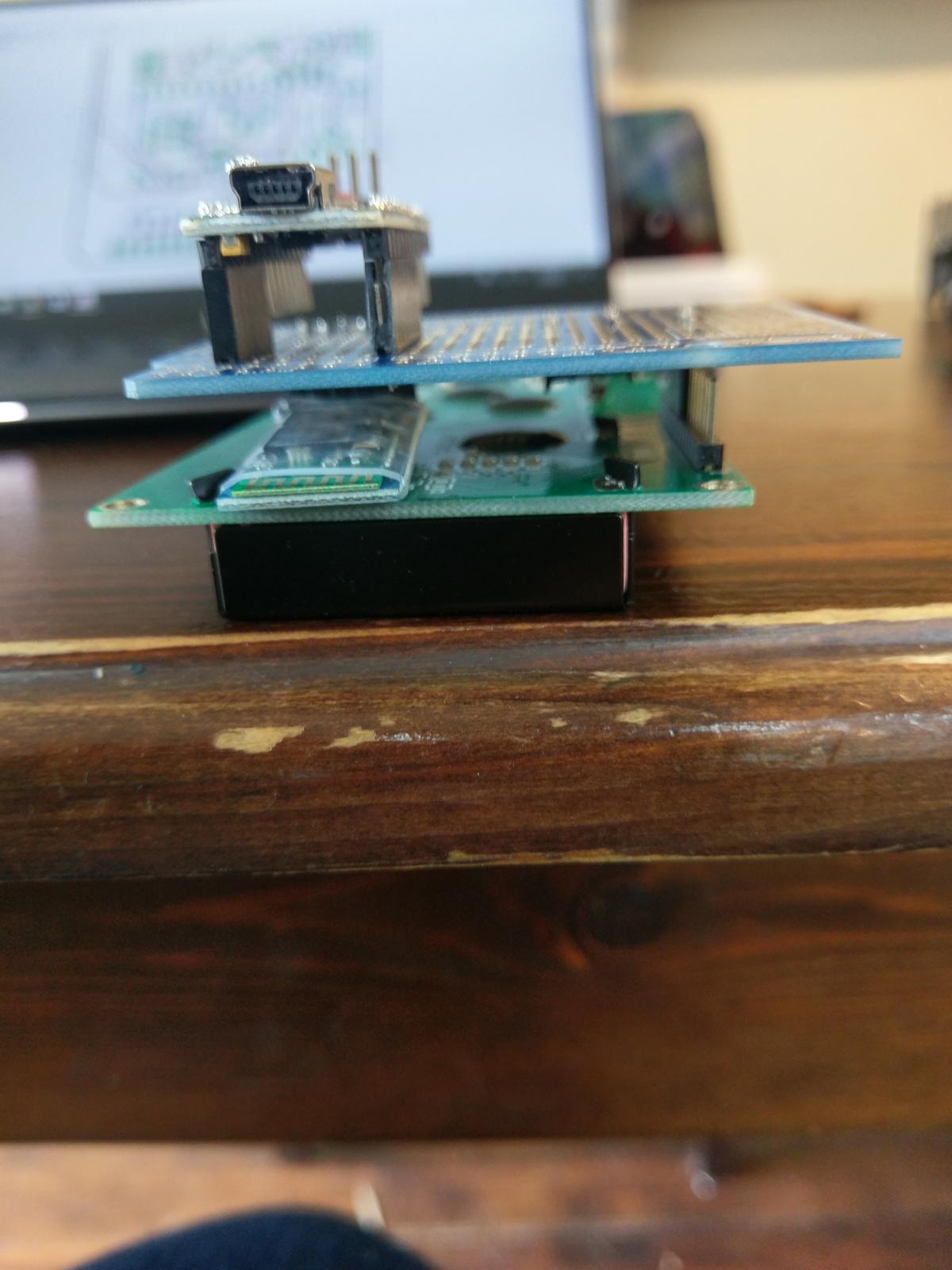

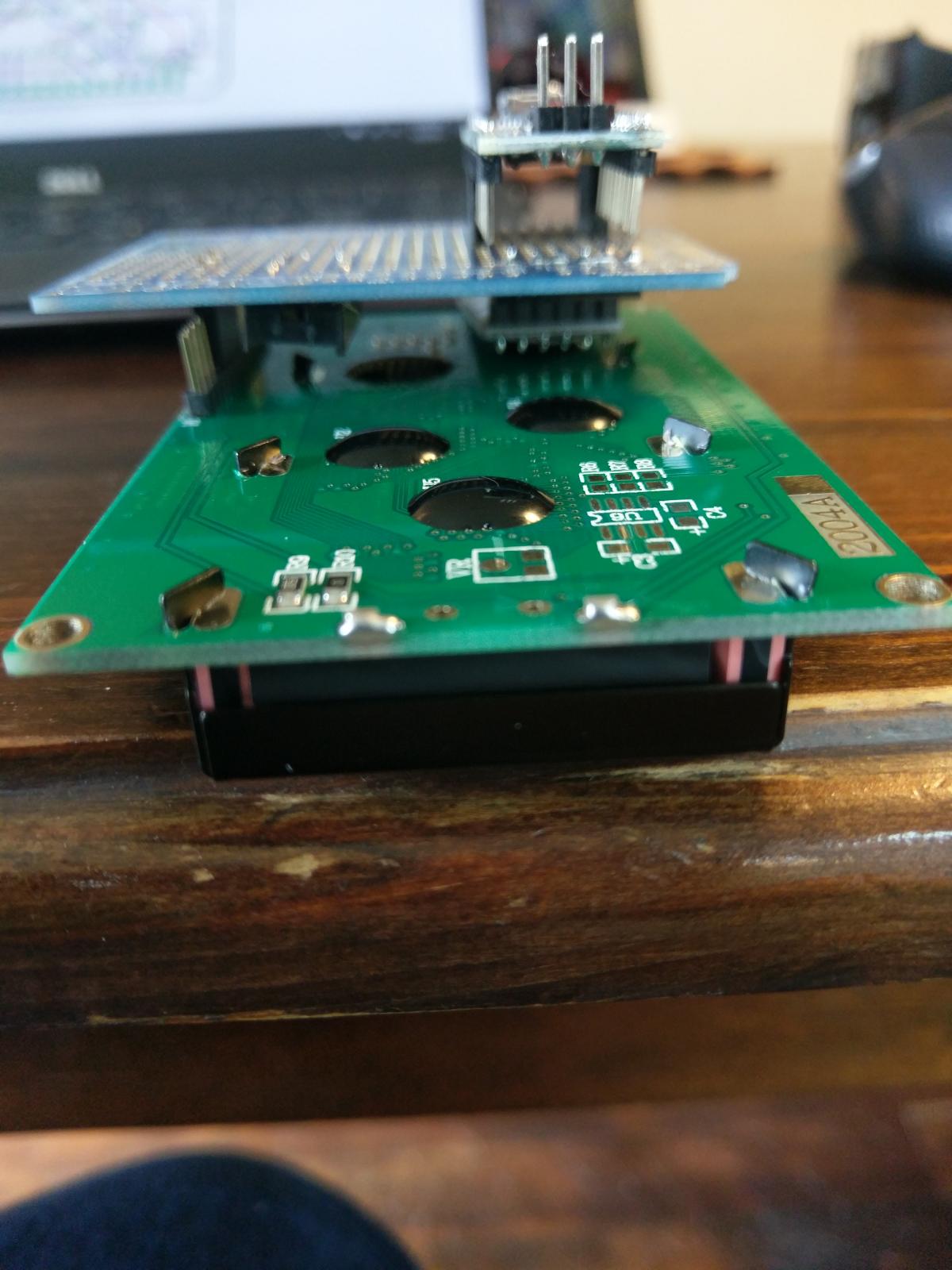

Here's a mock-up of how v2.0 will come together. Keep in mind that the proto shield that I sacrificed is longer and sticks out over the top of the LCD. The actual shield lines up with the top of the LCD. Also, the bluetooth radio antenna will stick out a bit further for better reception - I was limited on the proto shield for placement holes, so this was as close as I could approximate the location.

For space purposes, I had to put some caps and resistors under the Arduino, so you won't be able to solder the Arduino directly to the shield. I would think that most would want to use headers anyway, so this shouldn't be much of a sacrifice. That being said, one could solder the caps and resistors on the underside of the board instead of on top and you could still achieve soldering the Arduino directly to the shield. The downside to that (other than the obvious that you'd never be able to decouple your Arduino should you want to) is that the bluetooth module sits in the same area, so there may be minor clearance issues. If you were to keep the plastic wrapper around your bluetooth module, there shouldn't be any issues with metal touching metal.

I don't have the barrel connector for power input or an RJ11 jack yet, so I couldn't mock those up.

Anyone see anything that would be a deal-killer here?