Rivenin

Well-Known Member

- Joined

- Dec 13, 2010

- Messages

- 3,258

- Reaction score

- 342

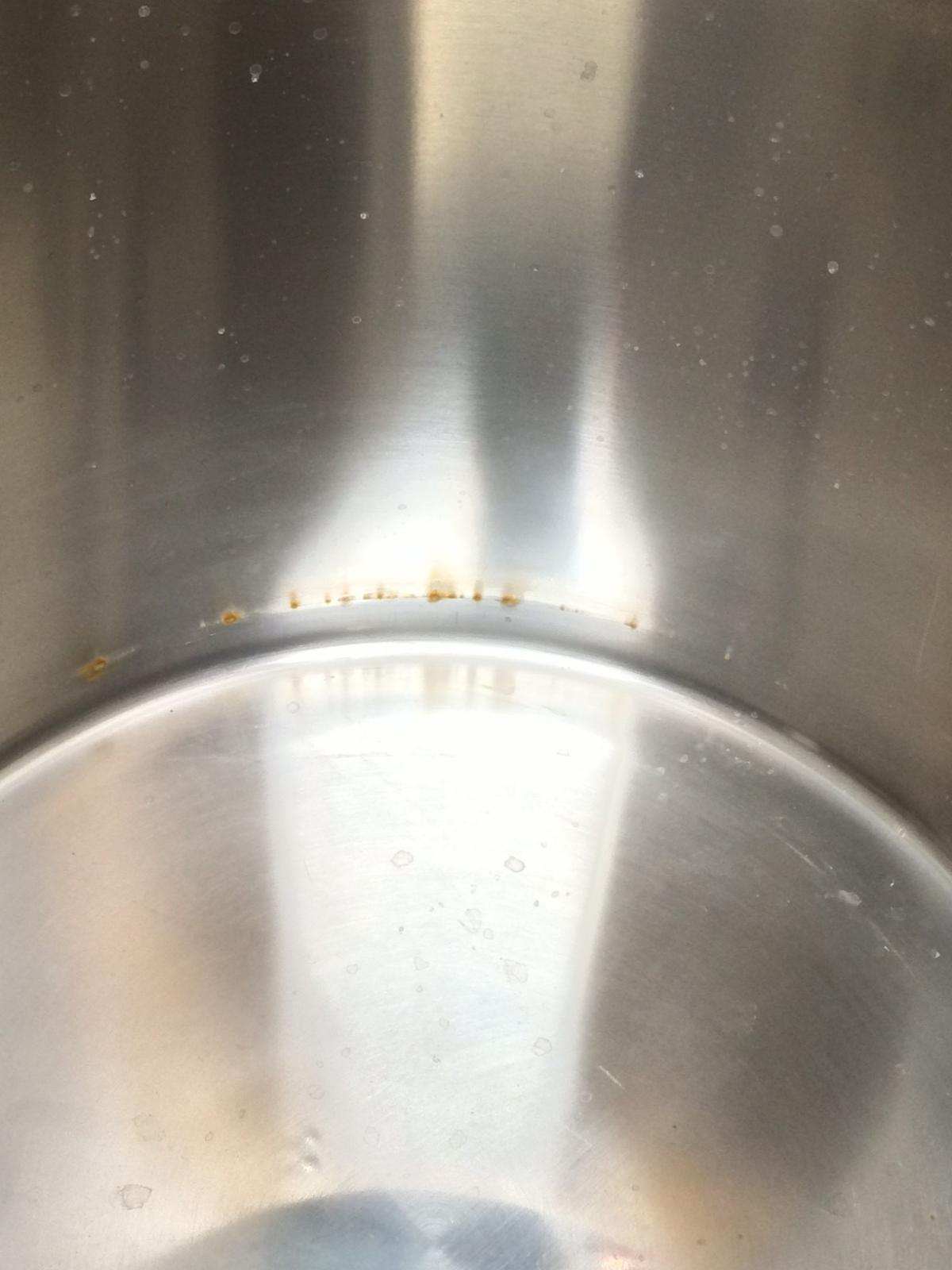

Just throwing this out there for everyone so they're aware. The infamous cheap concord kettles that are found around ebay, amazon, etc. Listed as 304 or 18/8-10 stainless.

They're some sort of unknown alloy.

Background on how i got this...

I work in a very large dental manufacturing company and spoke with one of our metals engineering people to see if they could weld one of my concord pots as they weld stainless on a regular basis for the dental world.

Gave him one of my older smaller concord kettles to weld on and play around with and practice on before he went to my large one... which i'm glad I did. He was having a hard time with just welding 2 pieces together, so he had our metallurgist guy run a certificate of validation on a piece of the metal twice and this is what he came up with. Attached the verification to my google drive which should work for everyone, if not, let me know.

C = Concord

201 = 201 stainless

301 = 301 stainless

below are the percentages of the concord based on what it's supposed to be

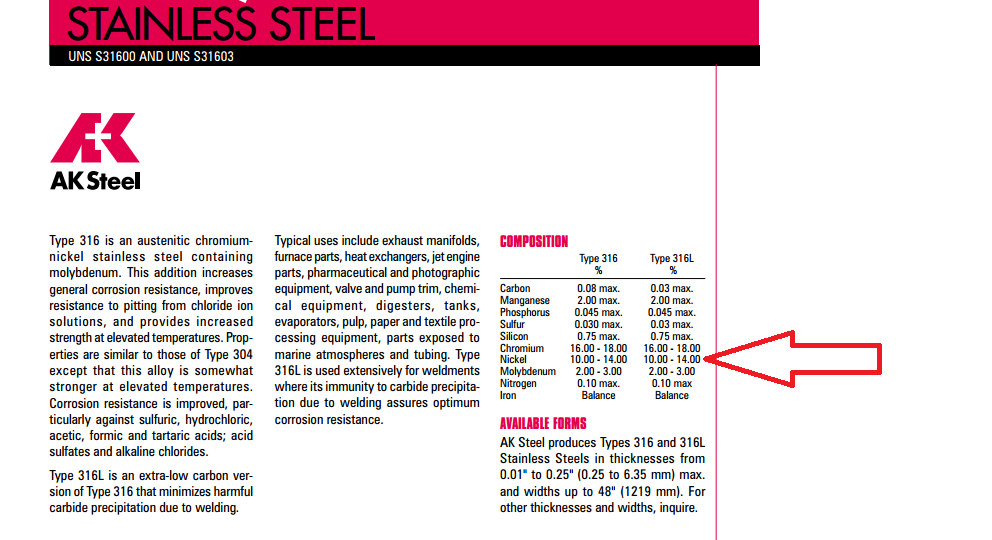

Concord ----- 201 ------- 301

FE --- 73

NI - 1.1 --- 3.5/5.5 --- 6.0/8.0

MN - 10 -----5.5/7.5 -- 2

CR - 13 ----- 16/18 ----16/18

although it's closest to 201 which is safe and i will continue to use mine for now. Just wanted people to be aware

this is what 201 is safe for BTW

---------------------------------------------------------------------------------

Typical Applications

Appliances, utensils and cutlery; restaurant; institutional and household furnishings such as pots, pans, flatware, counters, splash shields, sinks, dishwasher components, oven parts

Automotive trim, moldings, wiper arms, fastener parts

Architectural and construction hardware, hinges, doors, frames, roll formed sections

Food processing and handling, milk and dairy products, beer, wine, beverages, conveyors

Transportation, rapid transit cars, buses, aircraft, cargo containers

--------------------------------------------------------------------------------

https://drive.google.com/file/d/0Bzc821FkFkjhaFotbUlUZEpnV0k/view?usp=sharing

Type of---%Nickel----%Chromiium %Carbon %Manganese %Silicon % Nitrogen Corrosion Melting Youngs Moduluis

Steel mpy (1) Range x10^6 PSI

201------3.5 - 5.5-----16.0---18.0---0.15 max-----5.5 - 7.5-----1.0 max----0.25 max---------20-----2550 - 2650----28.0

301------6.0 - 8.0 -----16.0---18.0---0.15 max-----2.0 max-----1.0 max-----0------------------12 ----2550 - 2590-----28.0

302------8.0 - 10.0----17.0---19.0---0.15 max-----2.0 max-----1.0 max-----0-------------10 - 18----2550 - 2590-----28.0

304------8.0 - 10.5----18.0---20.0---0.08 max-----2.0 max-----1.0 max-----0--------------6 - 12 ----2550 - 2650-----28.0

309------19.0 - 22.0---24.0---26.0---0.2 max------2.0 max-----1.0 max-----0---------------5 - 9-----2550 - 2650-----29.0

They're some sort of unknown alloy.

Background on how i got this...

I work in a very large dental manufacturing company and spoke with one of our metals engineering people to see if they could weld one of my concord pots as they weld stainless on a regular basis for the dental world.

Gave him one of my older smaller concord kettles to weld on and play around with and practice on before he went to my large one... which i'm glad I did. He was having a hard time with just welding 2 pieces together, so he had our metallurgist guy run a certificate of validation on a piece of the metal twice and this is what he came up with. Attached the verification to my google drive which should work for everyone, if not, let me know.

C = Concord

201 = 201 stainless

301 = 301 stainless

below are the percentages of the concord based on what it's supposed to be

Concord ----- 201 ------- 301

FE --- 73

NI - 1.1 --- 3.5/5.5 --- 6.0/8.0

MN - 10 -----5.5/7.5 -- 2

CR - 13 ----- 16/18 ----16/18

although it's closest to 201 which is safe and i will continue to use mine for now. Just wanted people to be aware

this is what 201 is safe for BTW

---------------------------------------------------------------------------------

Typical Applications

Appliances, utensils and cutlery; restaurant; institutional and household furnishings such as pots, pans, flatware, counters, splash shields, sinks, dishwasher components, oven parts

Automotive trim, moldings, wiper arms, fastener parts

Architectural and construction hardware, hinges, doors, frames, roll formed sections

Food processing and handling, milk and dairy products, beer, wine, beverages, conveyors

Transportation, rapid transit cars, buses, aircraft, cargo containers

--------------------------------------------------------------------------------

https://drive.google.com/file/d/0Bzc821FkFkjhaFotbUlUZEpnV0k/view?usp=sharing

Type of---%Nickel----%Chromiium %Carbon %Manganese %Silicon % Nitrogen Corrosion Melting Youngs Moduluis

Steel mpy (1) Range x10^6 PSI

201------3.5 - 5.5-----16.0---18.0---0.15 max-----5.5 - 7.5-----1.0 max----0.25 max---------20-----2550 - 2650----28.0

301------6.0 - 8.0 -----16.0---18.0---0.15 max-----2.0 max-----1.0 max-----0------------------12 ----2550 - 2590-----28.0

302------8.0 - 10.0----17.0---19.0---0.15 max-----2.0 max-----1.0 max-----0-------------10 - 18----2550 - 2590-----28.0

304------8.0 - 10.5----18.0---20.0---0.08 max-----2.0 max-----1.0 max-----0--------------6 - 12 ----2550 - 2650-----28.0

309------19.0 - 22.0---24.0---26.0---0.2 max------2.0 max-----1.0 max-----0---------------5 - 9-----2550 - 2650-----29.0