moreb33rplz

Well-Known Member

- Joined

- Mar 25, 2014

- Messages

- 679

- Reaction score

- 358

I am 3 batches in my first BIAB batches. I do 2.5 gallon batches, and use a 5 gallong kettle and standard mesh bag.

First batch was about 50% efficiency, next 2 were about 60-65%. I made sure I had a super duper fine crush and squeezed/let drain the bag after mashing on the second 2.

But don't know what I can do to get higher? Ideally I'd like 70-75%. My mash temps are expected (low 150s), I stir like a mother and dont' notice doughballs, I don't measure but calcs say my pH should be OK, and my last 2 crushes have been very well crushed.

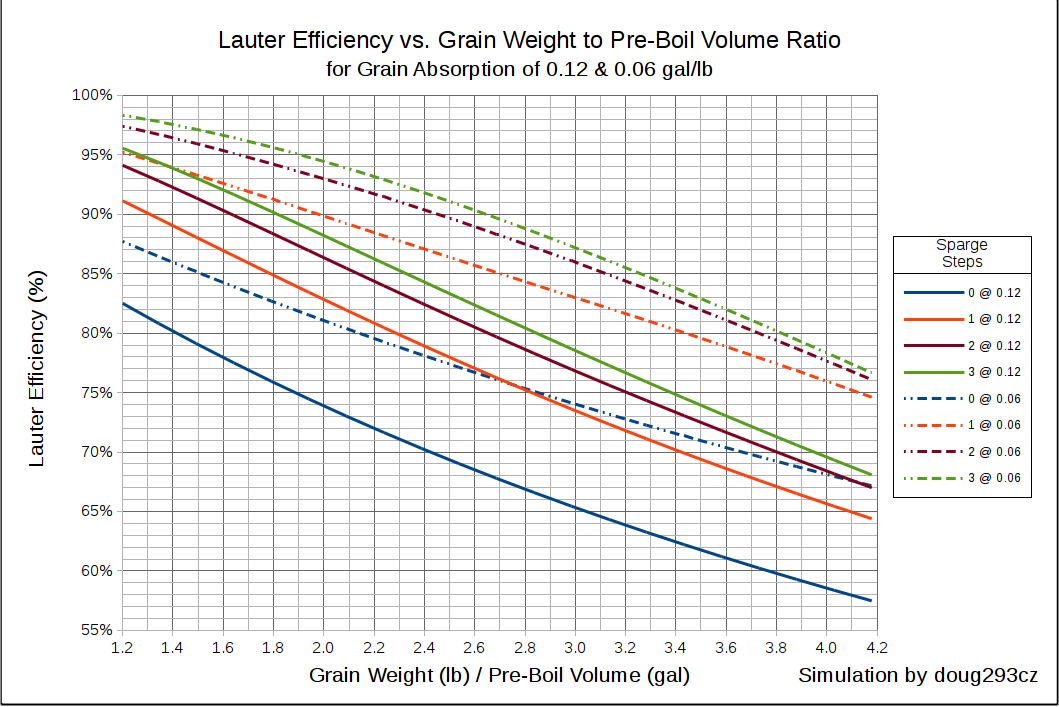

Only thing that is new for me is the mash grist ratio. I use 4 gallons for each beer to hit my pre-boil volume. So with 6'ish pounds of grain that's like 2.75-3 or something. I used to use 1.25-1.5 on my old grain system.

Does grist ratio affect efficiency?

First batch was about 50% efficiency, next 2 were about 60-65%. I made sure I had a super duper fine crush and squeezed/let drain the bag after mashing on the second 2.

But don't know what I can do to get higher? Ideally I'd like 70-75%. My mash temps are expected (low 150s), I stir like a mother and dont' notice doughballs, I don't measure but calcs say my pH should be OK, and my last 2 crushes have been very well crushed.

Only thing that is new for me is the mash grist ratio. I use 4 gallons for each beer to hit my pre-boil volume. So with 6'ish pounds of grain that's like 2.75-3 or something. I used to use 1.25-1.5 on my old grain system.

Does grist ratio affect efficiency?