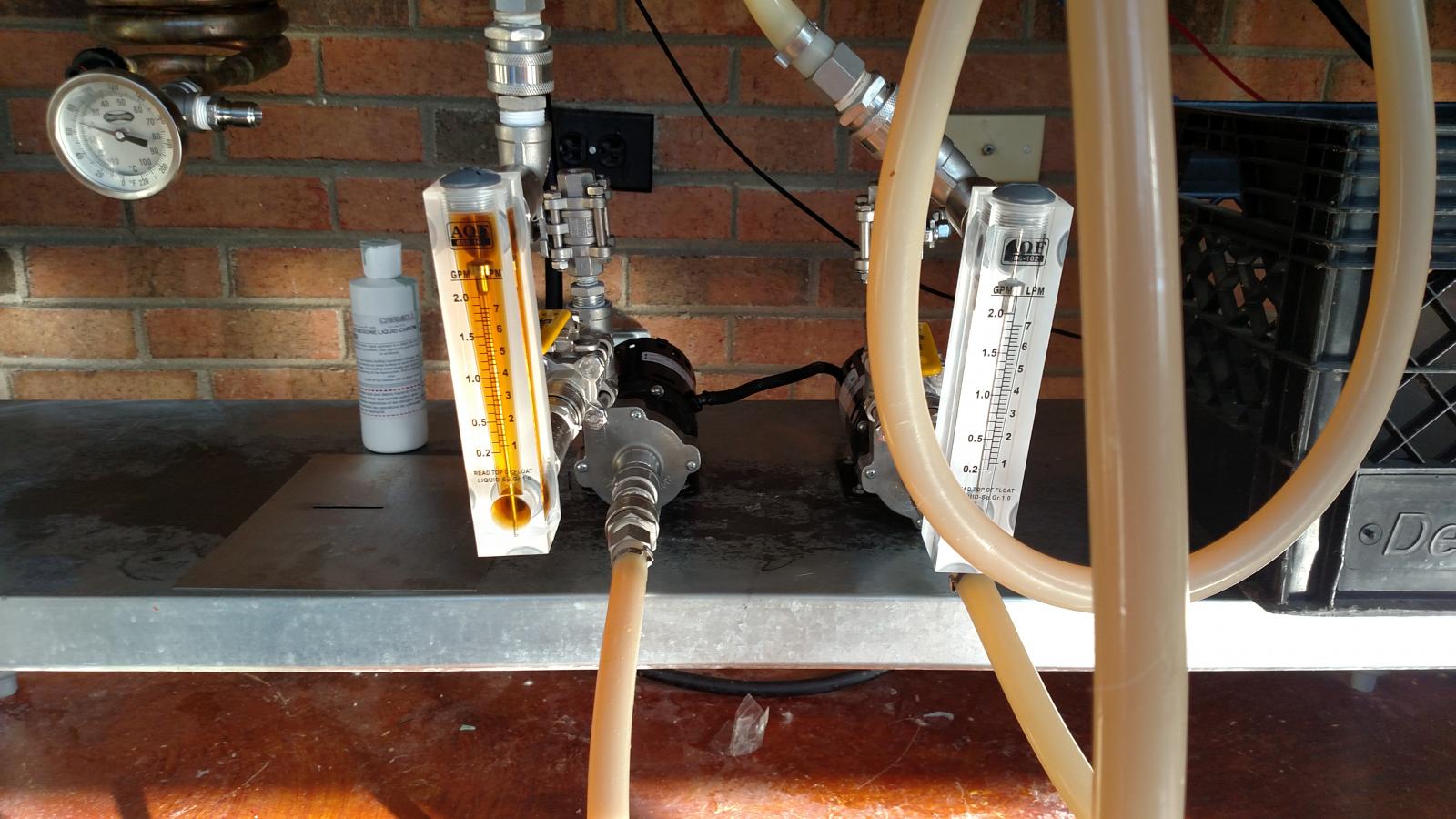

Hey brew science minds... I have worked hard to make a fly sparging system that appropriately feeds water to the top of the grain bed while simultaneously draining liquid off at a slow rate. This is the goal to fly sparging as so many resources have dictated.

Batch sparging requires draining of the MLT before adding sparge water.

So my question is... What is wrong with fly sparging where you would fully drain the MLT, then sprinkle hot water over the "dry" grains? This is common in BIAB practice for those who sparge, and I remember successfully sprinkling water over grains in a colander during my first homebrew trials.

Is it a compacted mash, tannin extraction, or channeling that is the concern? Seems like fly sparging would be infinitely easier if it were done this way. Thoughts?

Batch sparging requires draining of the MLT before adding sparge water.

So my question is... What is wrong with fly sparging where you would fully drain the MLT, then sprinkle hot water over the "dry" grains? This is common in BIAB practice for those who sparge, and I remember successfully sprinkling water over grains in a colander during my first homebrew trials.

Is it a compacted mash, tannin extraction, or channeling that is the concern? Seems like fly sparging would be infinitely easier if it were done this way. Thoughts?