Looking to do my first Mexican Lager this weekend. There are some things I am unsure of.

1. The lagering phase - how long does this need to be? I have it going for 4 - 6 weeks in my recipe sheet. Is that necessary?

2. I also have it scheduled to transfer to a secondary container. Is this necessary?

3. Can the lagering just be done in the serving keg for the required amount of time and once the lagering phase is complete, tap the keg...?

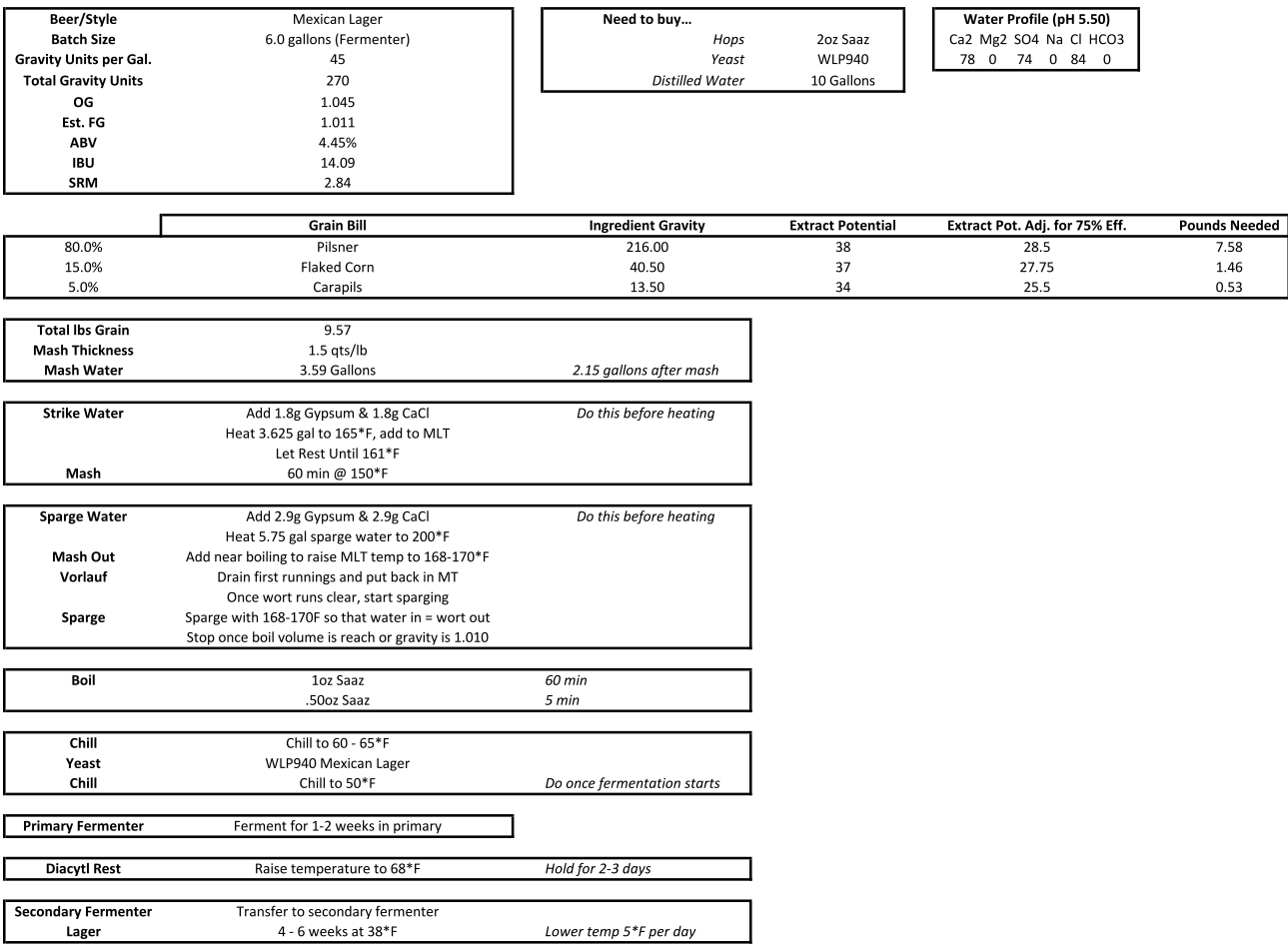

I have attached my brew day sheet with the recipe. Any other critiques are welcome. I have corn sugar in there but not sure if I should pull that and just add more grain....?

Thanks.

1. The lagering phase - how long does this need to be? I have it going for 4 - 6 weeks in my recipe sheet. Is that necessary?

2. I also have it scheduled to transfer to a secondary container. Is this necessary?

3. Can the lagering just be done in the serving keg for the required amount of time and once the lagering phase is complete, tap the keg...?

I have attached my brew day sheet with the recipe. Any other critiques are welcome. I have corn sugar in there but not sure if I should pull that and just add more grain....?

Thanks.