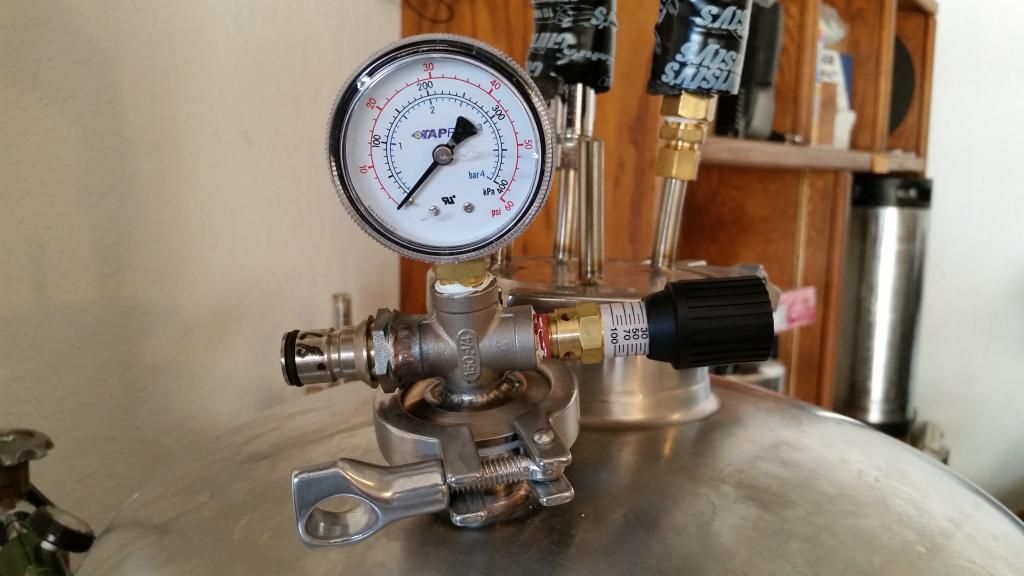

Hi Everybody! Curious amongst those of you pressurizing your conical fermenters, your experiences with the lids either slowly leaking pressure or holding firm amongst the various manufacturers out there. A lot of companies say that they're pressurizable to around 4-5 PSI for keg transfers, but I'm in the market for something that's able to hold a few PSI indefinitely for when I'm crashing or otherwise dropping temperature over a few days.

I got in touch with MoreBeer regarding their conical, and surprisingly the rep said they can only be pressurized during transfers and will otherwise slowly leak CO2 through the lid gasket. I got a similar response from SS Brew Tech when asking about the Chronical. It seems from reading that some people are having better luck holding pressure with the band-clamp style lids (MoreBeer, Blichmann) as opposed to the spring clip lids (Chronical) or the flat-top push down type like the Stout Tank models. Glacier Tanks say they're pressurizable to 14.7 PSI which is great, but the smallest fermenter that seem to make is 1 BBL. I'm looking more along the lines of a 7.5 gal, 14 gal only if it makes sense.

I got a similar response from SS Brew Tech when asking about the Chronical. It seems from reading that some people are having better luck holding pressure with the band-clamp style lids (MoreBeer, Blichmann) as opposed to the spring clip lids (Chronical) or the flat-top push down type like the Stout Tank models. Glacier Tanks say they're pressurizable to 14.7 PSI which is great, but the smallest fermenter that seem to make is 1 BBL. I'm looking more along the lines of a 7.5 gal, 14 gal only if it makes sense.

I'd love to hear any first-hand accounts of lid gasket designs and how well they are able to hold a few PSI long-term. Maybe there are some manufacturers I am overlooking? Thanks in advance!!

I got in touch with MoreBeer regarding their conical, and surprisingly the rep said they can only be pressurized during transfers and will otherwise slowly leak CO2 through the lid gasket.

I'd love to hear any first-hand accounts of lid gasket designs and how well they are able to hold a few PSI long-term. Maybe there are some manufacturers I am overlooking? Thanks in advance!!