FrozenWinter

Active Member

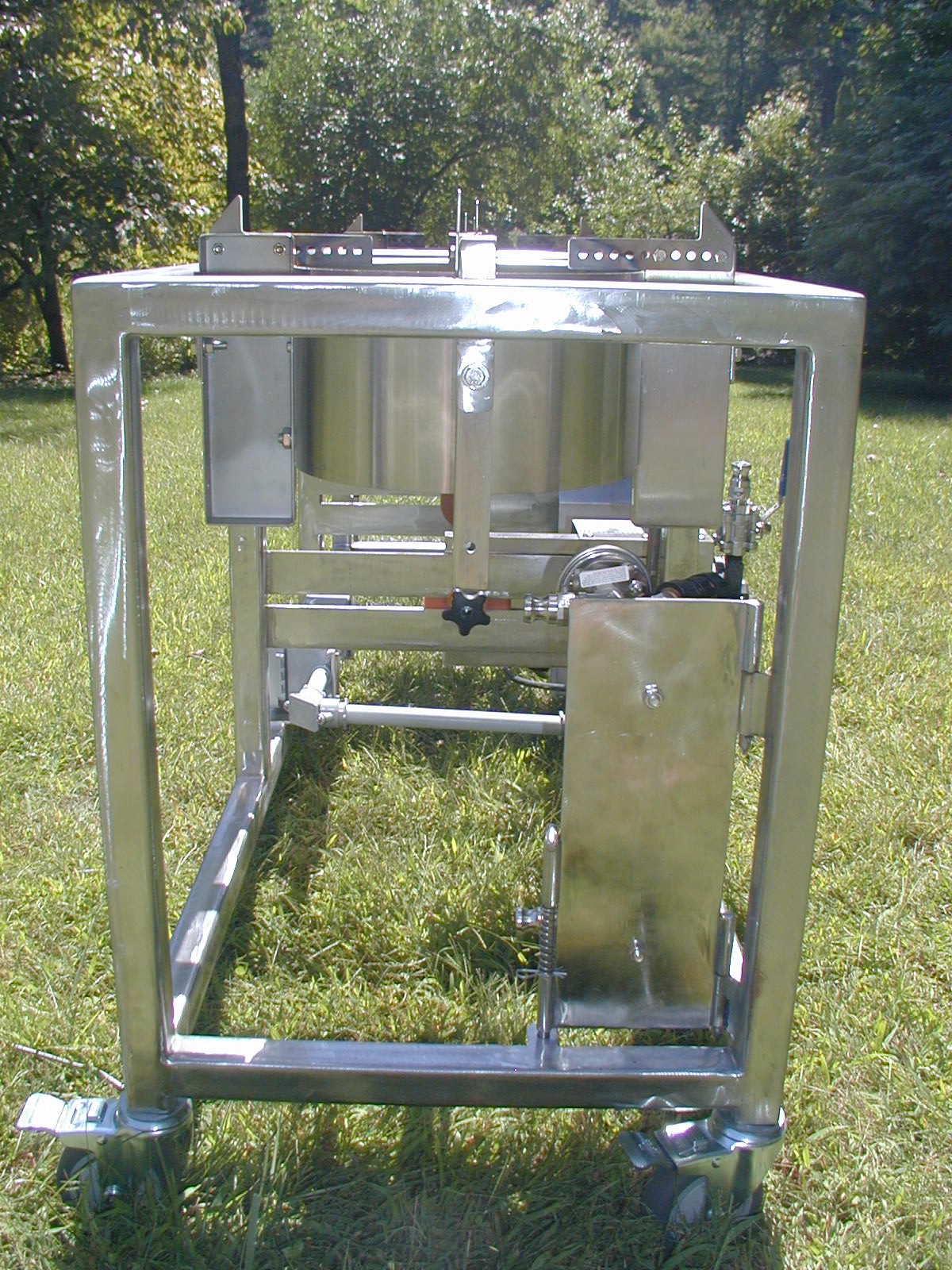

I'm currently designing a new brew stand to replace my old wooden 3 tier setup.

My new design is going to be a 2 tier set up with the HLT and MT on the top and a pump running the HLT to the MT and gravity feeding the MT to the BK.

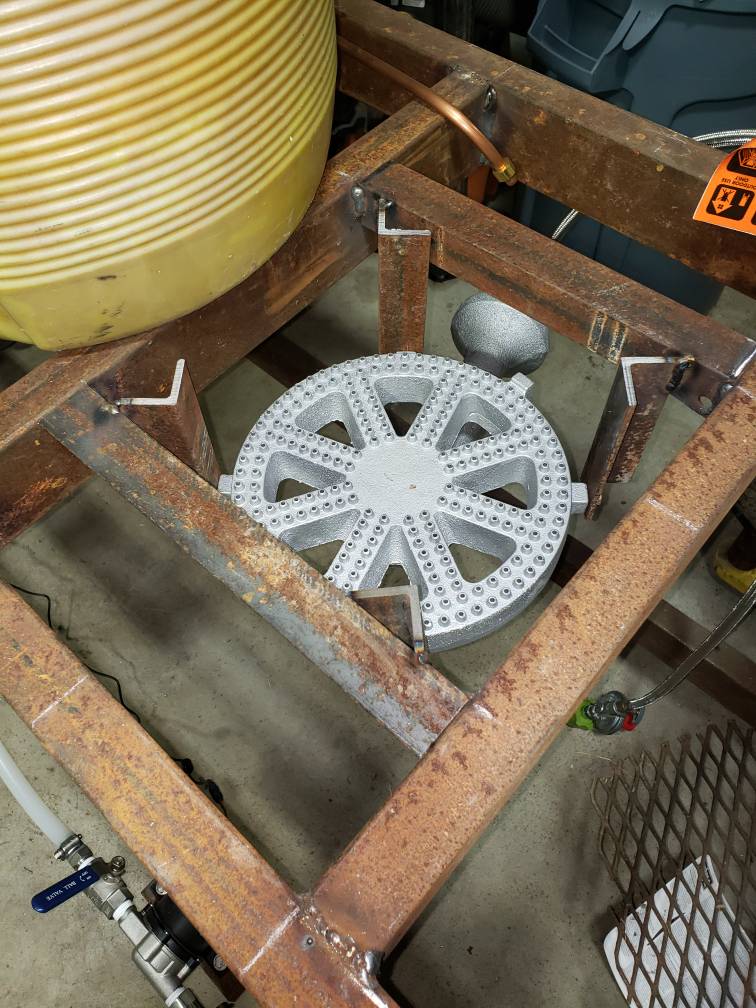

The problem im running into with the design is how to mount my burner to the stand.

The stand will be welded up out of 1"1/2 square tube and the burner I currently have is one of the older (non hellfire) Blichmann floor burners. I have the short legs and wind screen for it as well.

If i could see some pics or drawings of how other folk on here have mounted their burners It would be really helpful.

Thanks!

My new design is going to be a 2 tier set up with the HLT and MT on the top and a pump running the HLT to the MT and gravity feeding the MT to the BK.

The problem im running into with the design is how to mount my burner to the stand.

The stand will be welded up out of 1"1/2 square tube and the burner I currently have is one of the older (non hellfire) Blichmann floor burners. I have the short legs and wind screen for it as well.

If i could see some pics or drawings of how other folk on here have mounted their burners It would be really helpful.

Thanks!