I am in the process of building a new brewing rig and am down to the control panel. The HLT and boil kettle are propane and the Mashtun temperature is maintained by a a 120volt RIMS tube. The rig also has 2 pumps. I am only looking to control the HLT and the RIMS tube temperatures not the boil kettle. What controllers would best fit my needs? I was thinking either Auber's DSPR120 or DSPR300 for the RIMS tube but not sure about the HLT. Would anyone be able to help me with a wire diagram that I could use for my control panel? I would prefer if the element won't fire unless the pump is on. Looking for suggestions......Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Control panel help needed

- Thread starter vsforg

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

highland_brewer

Short Circuited Brewers

I did a RIMS system build on my youtube channel. It does have the interlock that you are looking for. Here is a link: RIMS

BUILD The diagram can be found here: https://www.homebrewtalk.com/showthread.php?t=597915 @doug293cz will see this and chime in for sure.. he is a WEALTH of knowledge for wiring digrams. Hope that helps! (You can use the output in the diagram for the boil kettle to any vessel)

BUILD The diagram can be found here: https://www.homebrewtalk.com/showthread.php?t=597915 @doug293cz will see this and chime in for sure.. he is a WEALTH of knowledge for wiring digrams. Hope that helps! (You can use the output in the diagram for the boil kettle to any vessel)

I have the DSPR120 for both, their very handy to use

so is the hlt propane too?

highland_brewer

Short Circuited Brewers

so is the hlt propane too?

When I originally read it I thought he wanted to electrically fire the rims tube and the HLT but now I'm not sure.

When I originally read it I thought he wanted to electrically fire the rims tube and the HLT but now I'm not sure.

The HLT and boil kettle are propane

Ok, here's a design for a 120V 15A RIMS controller. https://www.homebrewtalk.com/showpost.php?p=7935106&postcount=31

The rig also has 2 pumps. I am only looking to control the HLT and the RIMS tube temperatures not the boil kettle.... I would prefer if the element won't fire unless the pump is on. Looking for suggestions......Thanks

If I'm reading the OP right it looks like he is looking for a pretty specific wiring diagram. He will need to energize a solenoid valve for the propane burner on the HLT plus an igniter if there is no pilot flame on the HLT burner -AND- have a relay that will cut power to the solenoid used with the HLT unless the pump is energized. In addition there will need to be a power supply to the RIMS. Both the HLT and the RIMS to be controlled by a DSPR power regulator.

Way beyond my abilities! I have looked through numerous schematics posted here -love looking at the these just to see how it all works together! Not sure I have ever seen a schematic for this set up... maybe one out there? @doug293cz - Help

Cheers!

Sorry I did not read your op right. That controller is for the RIMS only (and two pumps)

But if you look back to the first page of the thread I linked you will see comments by @jrcrilly, he is the one with the info on the gas controller that I was considering building. I built a parts list for the gas system based off his articles, it is there too. Auber Ins. has a two controller box that I bet would fit both systems.

I am gonna be awfully jealous if you build this controller you want. Be sure to post up if you do, I am sure lots of hybrid brewers would be interested.

But if you look back to the first page of the thread I linked you will see comments by @jrcrilly, he is the one with the info on the gas controller that I was considering building. I built a parts list for the gas system based off his articles, it is there too. Auber Ins. has a two controller box that I bet would fit both systems.

I am gonna be awfully jealous if you build this controller you want. Be sure to post up if you do, I am sure lots of hybrid brewers would be interested.

I am in the process of building a new brewing rig and am down to the control panel. The HLT and boil kettle are propane and the Mashtun temperature is maintained by a a 120volt RIMS tube. The rig also has 2 pumps. I am only looking to control the HLT and the RIMS tube temperatures not the boil kettle. What controllers would best fit my needs? I was thinking either Auber's DSPR120 or DSPR300 for the RIMS tube but not sure about the HLT. Would anyone be able to help me with a wire diagram that I could use for my control panel? I would prefer if the element won't fire unless the pump is on. Looking for suggestions......Thanks

Either of the DSPR's will work for the RIMS tube, but which to choose depends on what you want in the way of alarms and external alarm relays (the 300 has more alarm features.)

You cannot drive a solenoid valve with a DSPR, as the output pulse cycles are too fast, and not adjustable. Therefore you need to select a PID which can be set to a longer output cycle, or even a simple on-off controller if +/- a couple of degrees is good enough for the HLT.

I haven't tried designing a gas controller, but maybe it's time to take on a new challenge. Are you looking to have a pilot light, or igniter based system?

Brew on

an easy way to set up the propane hlt is just to monitor the temp and possibly have an alarm turn on at the set time, like above you could do a igniter with a button on the control panel just for convenience but a on and off from the control panel to lite the flame manually would require an electric valve meant for gas, probably too much money for what it does

I like the idea of an the extra alarm features of the 300. The gas valve I picked up is a Honeywell VR8300A 3500 with a standing pilot light. Would a SYL-2342 be a good choice for a PID? If your up for the challenge of designing a hybrid controller I'd sure appreciate itEither of the DSPR's will work for the RIMS tube, but which to choose depends on what you want in the way of alarms and external alarm relays (the 300 has more alarm features.)

You cannot drive a solenoid valve with a DSPR, as the output pulse cycles are too fast, and not adjustable. Therefore you need to select a PID which can be set to a longer output cycle, or even a simple on-off controller if +/- a couple of degrees is good enough for the HLT.

I haven't tried designing a gas controller, but maybe it's time to take on a new challenge. Are you looking to have a pilot light, or igniter based system?

Brew on

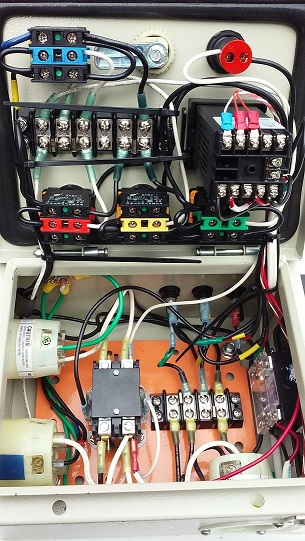

I built one for a friend before I found out about the DSPR, this is just a simple brew in a bag but the set up could work buy adding switches and another temp probe

I like the idea of an the extra alarm features of the 300. The gas valve I picked up is a Honeywell VR8300A 3500 with a standing pilot light. Would a SYL-2342 be a good choice for a PID? If your up for the challenge of designing a hybrid controller I'd sure appreciate it

That valve looks pretty simple to incorporate in a design, based on what @jrcrilly shows, and the specs say it can be used with NG or LP.

Yes a SYL-2342 is a suitable PID for the gas valve.

Brew on

Both the valve and the pilot come equipped with parts to configure for either fuel. Only a new burner orifice would have to be acquired to switch from one to the other. I think I will switch my rig over to NG this season.

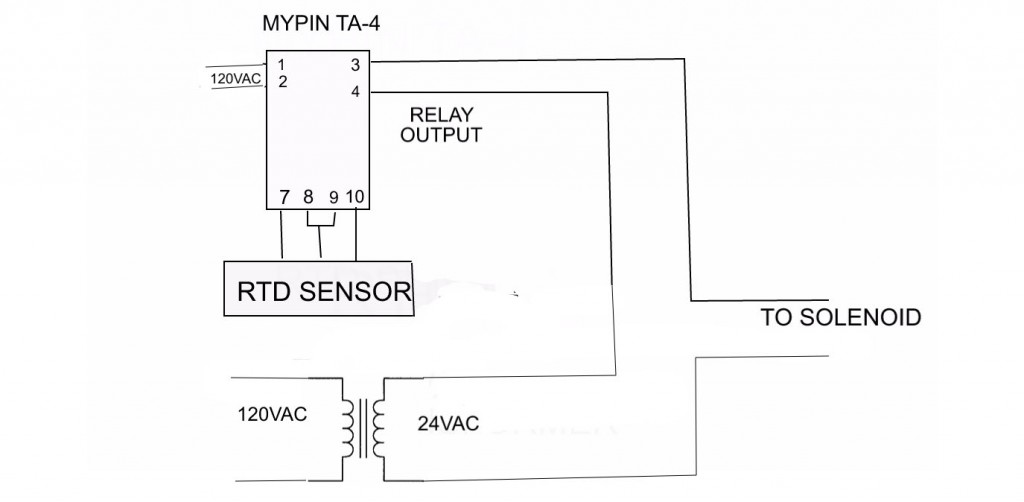

The SYL PID looks fine but I haven't tested one in this configuration. I am using three of the Mypins (half the price) and I know that they work in this setup.

The SYL PID looks fine but I haven't tested one in this configuration. I am using three of the Mypins (half the price) and I know that they work in this setup.

What model MyPins are you using? The most common one for brewery control is the TD4-SNR, however that output of this model is for driving SSR's. You could use a low voltage SSR to switch the solenoid valve, but that requires an extra component. I think you would want a TA4-RNR or TD4-RNR, which have an NO relay for the primary output, which can switch the solenoid directly. The TA4 does not have a manual contol mode, but you may not want this for an HLT.

Brew on

The articles linked to above discuss the requirements for appropriate PID modules as well as alternative non-PID controllers that have been tested here. They describe the specific PID modules I use in my system and why they were selected. As stated there, I use the TA4-RNR.

What would I need to do to use diagram at 120V and incorporate a SYL-2342 and gas valve?That valve looks pretty simple to incorporate in a design, based on what @jrcrilly shows, and the specs say it can be used with NG or LP.

Yes a SYL-2342 is a suitable PID for the gas valve.

Brew on

Follow the diagrams and construction articles posted above. Just change the pinouts to reflect those of a different PID if you choose to change that.

@vsforg

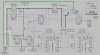

Here's the design for a 120V RIMS system with PID controlled propane fired HLT. The circuit has a "Safe Start" interlock so that main power cannot be turned on if either of the pump switches, the RIMS power enable switch or the gas solenoid enable switch are on. It also interlocks the RIMS power enable switch with the RIMS pump switch so that power cannot be enabled to the RIMS element unless the pump is on. I show a NEMA L6-30 receptacle on the power output since a lot of folks are starting to use the SS element with integrated L6-30 plugs on them. If you have any questions about the design, just ask. I did forget to change the input power requirement to 120V, 20A GFCI (the 240V, 30A is a holdover from the drawing I modified to make this one.)

Brew on

Here's the design for a 120V RIMS system with PID controlled propane fired HLT. The circuit has a "Safe Start" interlock so that main power cannot be turned on if either of the pump switches, the RIMS power enable switch or the gas solenoid enable switch are on. It also interlocks the RIMS power enable switch with the RIMS pump switch so that power cannot be enabled to the RIMS element unless the pump is on. I show a NEMA L6-30 receptacle on the power output since a lot of folks are starting to use the SS element with integrated L6-30 plugs on them. If you have any questions about the design, just ask. I did forget to change the input power requirement to 120V, 20A GFCI (the 240V, 30A is a holdover from the drawing I modified to make this one.)

Brew on

@doug293cz

Thanks so much. Now to buy the parts I need and get the panel assembled. I'll be sure to post some pics when I complete.

Thanks so much. Now to buy the parts I need and get the panel assembled. I'll be sure to post some pics when I complete.

You don't have to use the exact same components that are called out in the design. You can use any functionally equivalent part with equal, or higher, voltage/current ratings. Calling out the Auber PN's just gives you something you can look up to get more info on its function and ratings. Note that the SW11/SW16 switches called out all have one NO contact pair and one NC contact pair. SW11's only come that way, but SW16's must be specified as 1-NO, 1-NC when ordering. If there is a lamp voltage option for the switches, choose 120V.

Brew on

Brew on

Similar threads

- Replies

- 10

- Views

- 804

- Replies

- 1

- Views

- 553

- Replies

- 2

- Views

- 419