I'm in the midst of laying out my hop trellis design for some trials starting this spring and I have a couple questions regarding what people are using for their designs and dimensions.

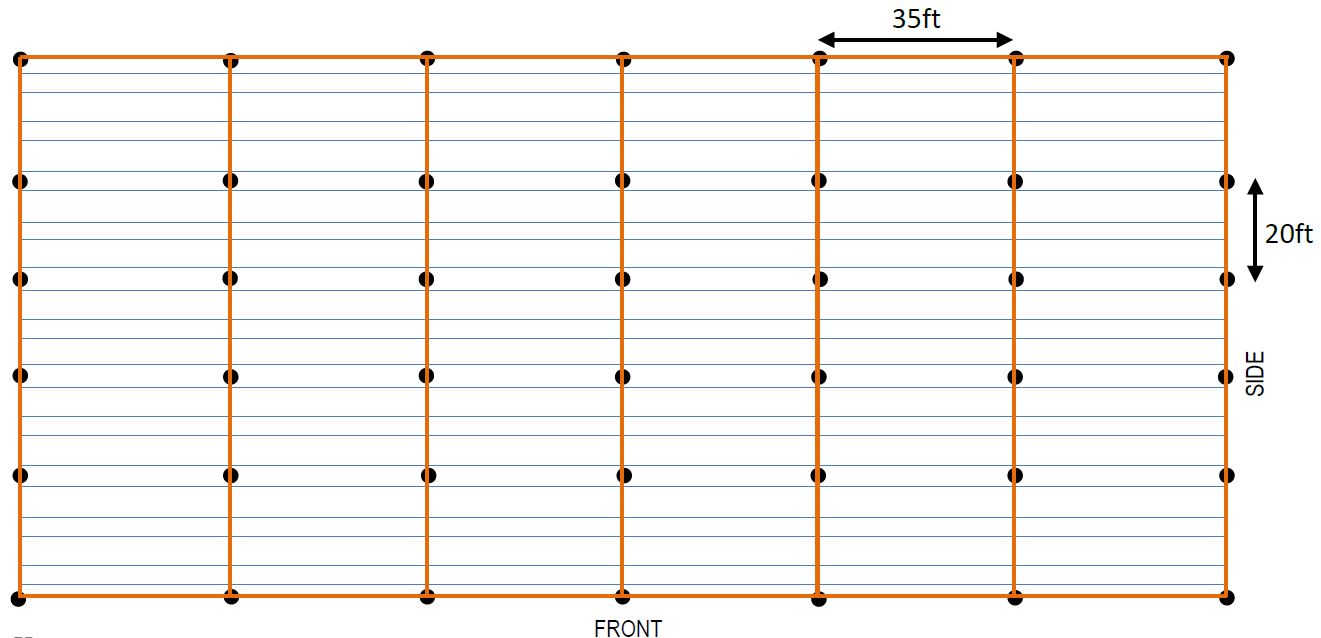

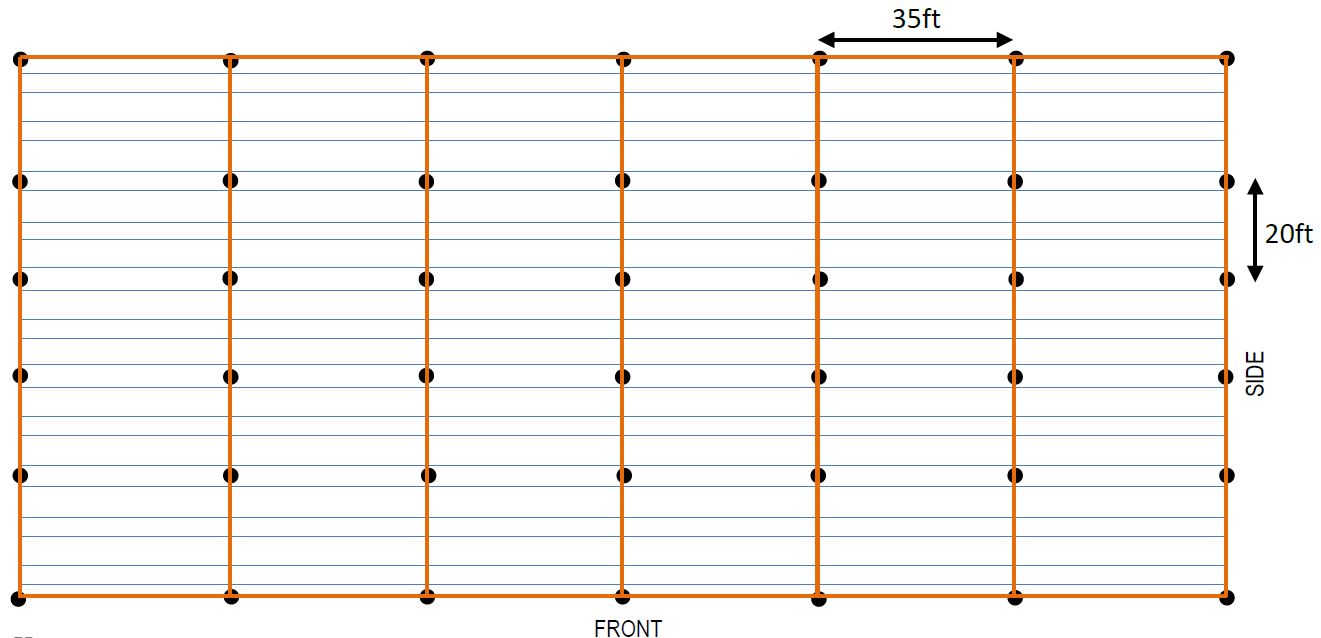

From what I have read, a 35' pole spacing in my rows is sufficient for growing cascade hops comfortably, however my real concern pertains to the row spacing itself. Some have indicated 10' spacing between poles whereas others use 20'. With the 20' spacing, there appears to be the same amount of vine lines but with less support (See Attach'd). What setup has everyone had the best experiences with? And if sizes do work, does one method require less maintenance than the other over time, i.e. wire rope sag?

Also, what has everyone used for wire rope sizes? Support lines? Main Lines? Vine Lines?

My test area will be 40' by 140'

Mike

From what I have read, a 35' pole spacing in my rows is sufficient for growing cascade hops comfortably, however my real concern pertains to the row spacing itself. Some have indicated 10' spacing between poles whereas others use 20'. With the 20' spacing, there appears to be the same amount of vine lines but with less support (See Attach'd). What setup has everyone had the best experiences with? And if sizes do work, does one method require less maintenance than the other over time, i.e. wire rope sag?

Also, what has everyone used for wire rope sizes? Support lines? Main Lines? Vine Lines?

My test area will be 40' by 140'

Mike