birch

Member

Commercial brewery cleaning cycles first use alkaline cleaners to remove organic deposits (mainly yeast crud) but it also helps remove the protein crud on elements, followed by a rinse and then acid to sanitize.

-PBW is the home brewer friendly alkaline cleaner; the right kind of dishwasher tabs can work too but you REALLY need to research them. Bringing the water + PBW up to boiling does a lot of the work for you but won't fully remove the crud -simply rub it with a wash cloth and it will be clean in a jiffy!

If you don't want to scrub just use Citric Acid (available at most home brew shops in a crystaline form over by the wine ingredients) and water and boil it for a few minutes. -The stuff is magical and will clean the element 100% without scrubbing.

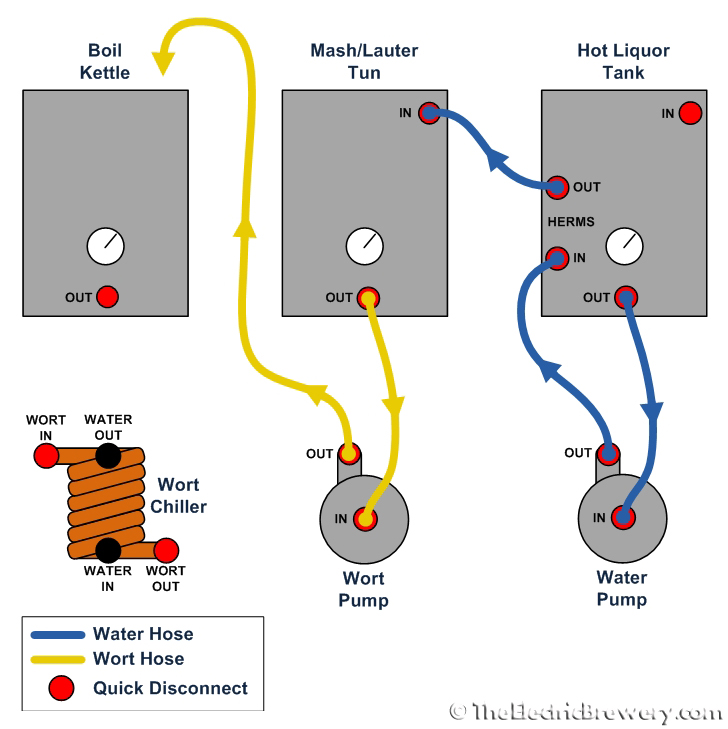

I add 1-2 gallons extra into my HLT and then while the boil is happening add PBW to my HLT water and start dismantling my mash fitting and hoses and then I soak them in the HLT water after it gets hot for a while; I then recirc the liquid from the HLT through my pumps and mashtun and then after chilling and transferring the liquid out of my BK and rinsing it, I pump the PBW into the BK and power up it's element for 5ish minutes. -A quick scrub with a rag and the elements are 95% clean.

Every 3rd-5th brew I boil with citric acid. I also rotate my elements between my boil kettle and my HLT which helps too (tri clamp fittings are SO easy to swap).

I've only ever brewed with electric elements; I was in Ireland the last 5 years and almost everyone there boils with electric elements as 240v power everywhere and very expensive propane makes it a no brainer.

Adam

How much citric acid do you use per gallon?