EspetoHomebrewing

Member

- Joined

- Mar 12, 2022

- Messages

- 11

- Reaction score

- 37

Hi guys,

I'm new to the forum, although I've been following you from the shadows for a long time. First of all, sorry for my bad English, I'm from Spain and I'm a bit oxidated on the Shakespeare language.

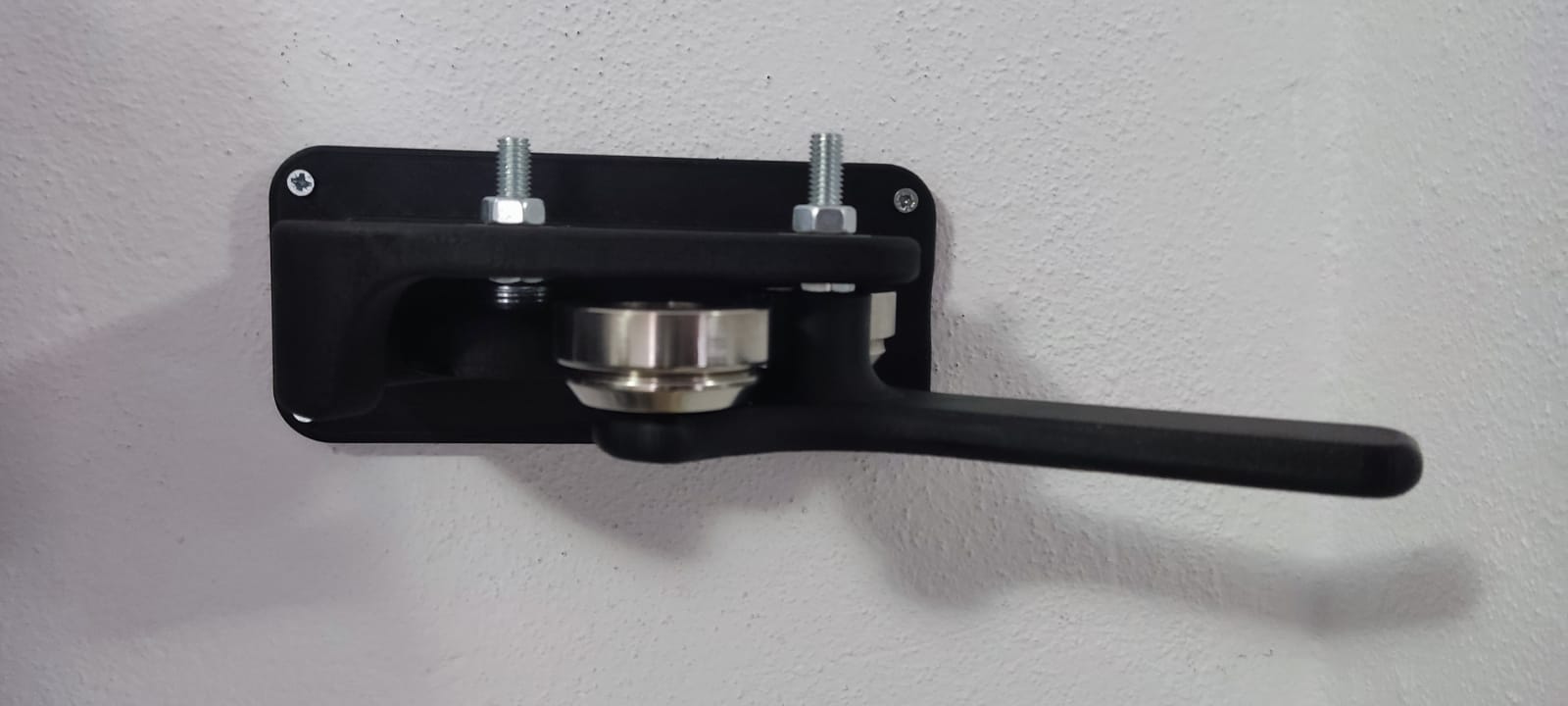

I'd like to start in this community sharing with you my new project, a 3D Printed Can Seamer.

My main idea, to save effort in a solid structure, is that the sealer was anchored to the wall, so the wall would be the structure. I've already used this idea whit my counter pressure filler support (I'll make a post ASAP with the design pieces)

So, for now I can tell you, I've been designing the top part main pieces:

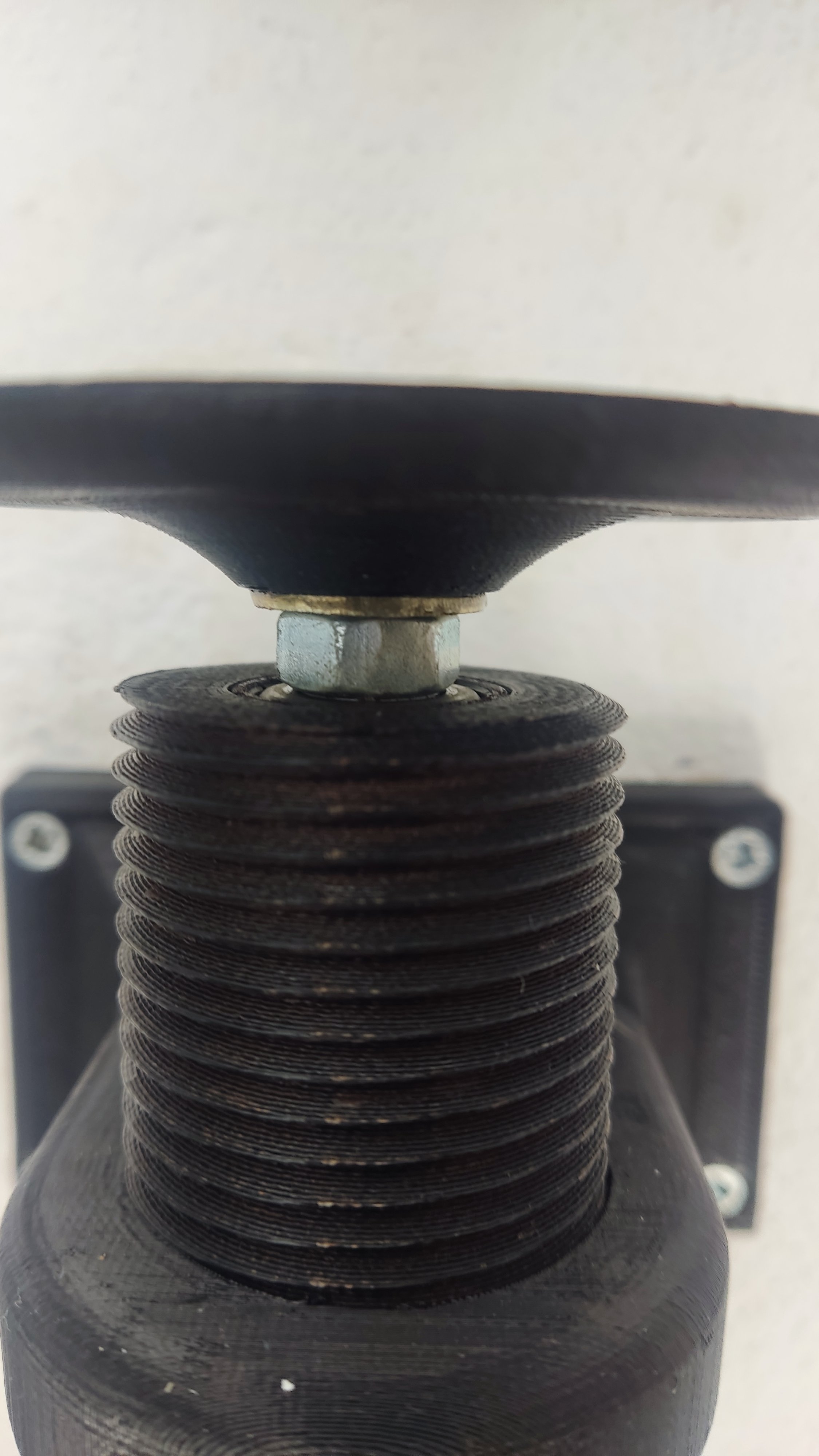

And printed the most difficult part. The piece that would fit the lid of the can:

Apart from screws, nuts and bearings (which I will specify when I check that everything fits), the only metal parts that I cannot print and need to be purchased are the two sealing wheels:

1st Op Roller

2nd Op Roller

I'll be back with more updates soon!! Stay tuned!

I'm new to the forum, although I've been following you from the shadows for a long time. First of all, sorry for my bad English, I'm from Spain and I'm a bit oxidated on the Shakespeare language.

I'd like to start in this community sharing with you my new project, a 3D Printed Can Seamer.

My main idea, to save effort in a solid structure, is that the sealer was anchored to the wall, so the wall would be the structure. I've already used this idea whit my counter pressure filler support (I'll make a post ASAP with the design pieces)

So, for now I can tell you, I've been designing the top part main pieces:

And printed the most difficult part. The piece that would fit the lid of the can:

Apart from screws, nuts and bearings (which I will specify when I check that everything fits), the only metal parts that I cannot print and need to be purchased are the two sealing wheels:

1st Op Roller

2nd Op Roller

I'll be back with more updates soon!! Stay tuned!