bjhbrew

Well-Known Member

- Joined

- Oct 15, 2016

- Messages

- 157

- Reaction score

- 79

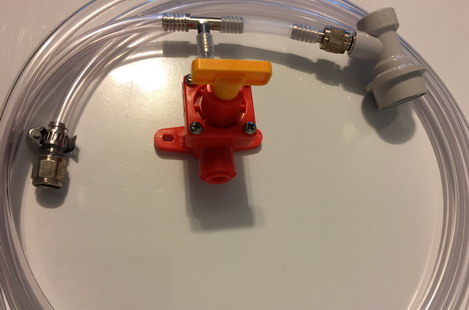

Alright I’ve been thinking about this a lot so this’ll probably be a longer post. I recently bought the 35L snub nose fermentasaurus fermenter and I’d like to make use of its pressure rating. First off I’m hoping that using a spunding valve set low (maybe 5 psi) can help to keep the Krausen down so I can fill the fermenter pretty full (30L). Then I’d like to raise the pressure to carbonate naturally while limiting any o2 ingress. Pretty standard stuff so far but my final goal is to also use the co2 produced during fermentation to purge my serving keg so I’m wondering if it matters/makes a difference if the spunding valve goes between the vessels or after the serving keg? I attached a couple diagrams below to illustrate what I think are my options:

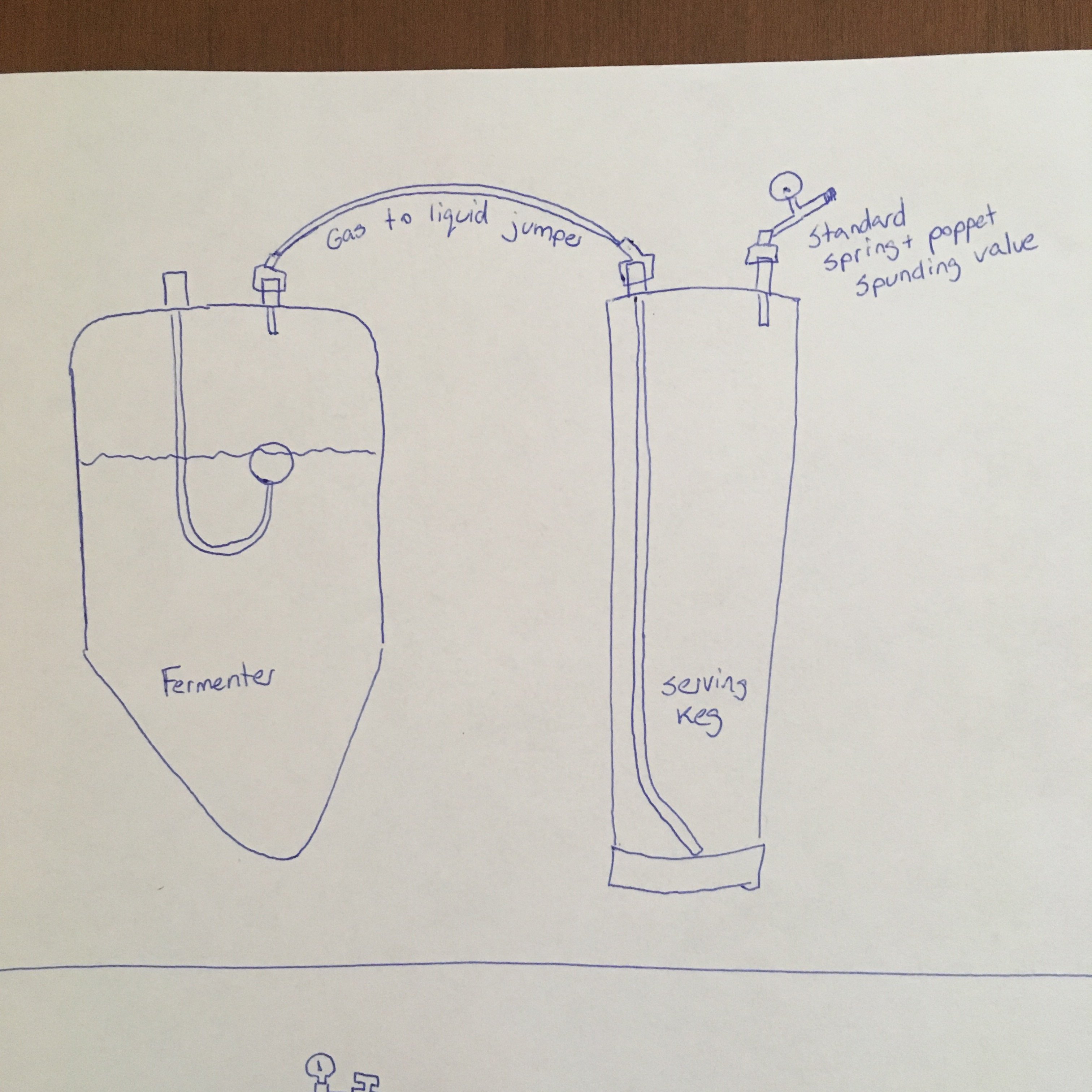

Option 1:

Jumper between the gas post of the fermenter to the liquid post of the serving keg. Put a typical spring and poppet style spunding valve on the gas post of the serving keg set to 5 psi and it’s ready to go

Pros:

No blow off liquid, airlock, or extra hose needed (less cleaning)

I can buy all the stuff at my LHBS

Concerns:

I’m concerned that 5 psi might not be enough to seal the lid which means the fermenter won’t get pressurized and krausen could get up in the jumper/serving keg.

I’ve heard that spring and poppet spunding valves tend to leak so I might have to keep a closer eye on this at the tail end of fermentation. I like to be pretty hands off and give plenty of time in primary 2 weeks plus so I’d rather not have to futz with it.

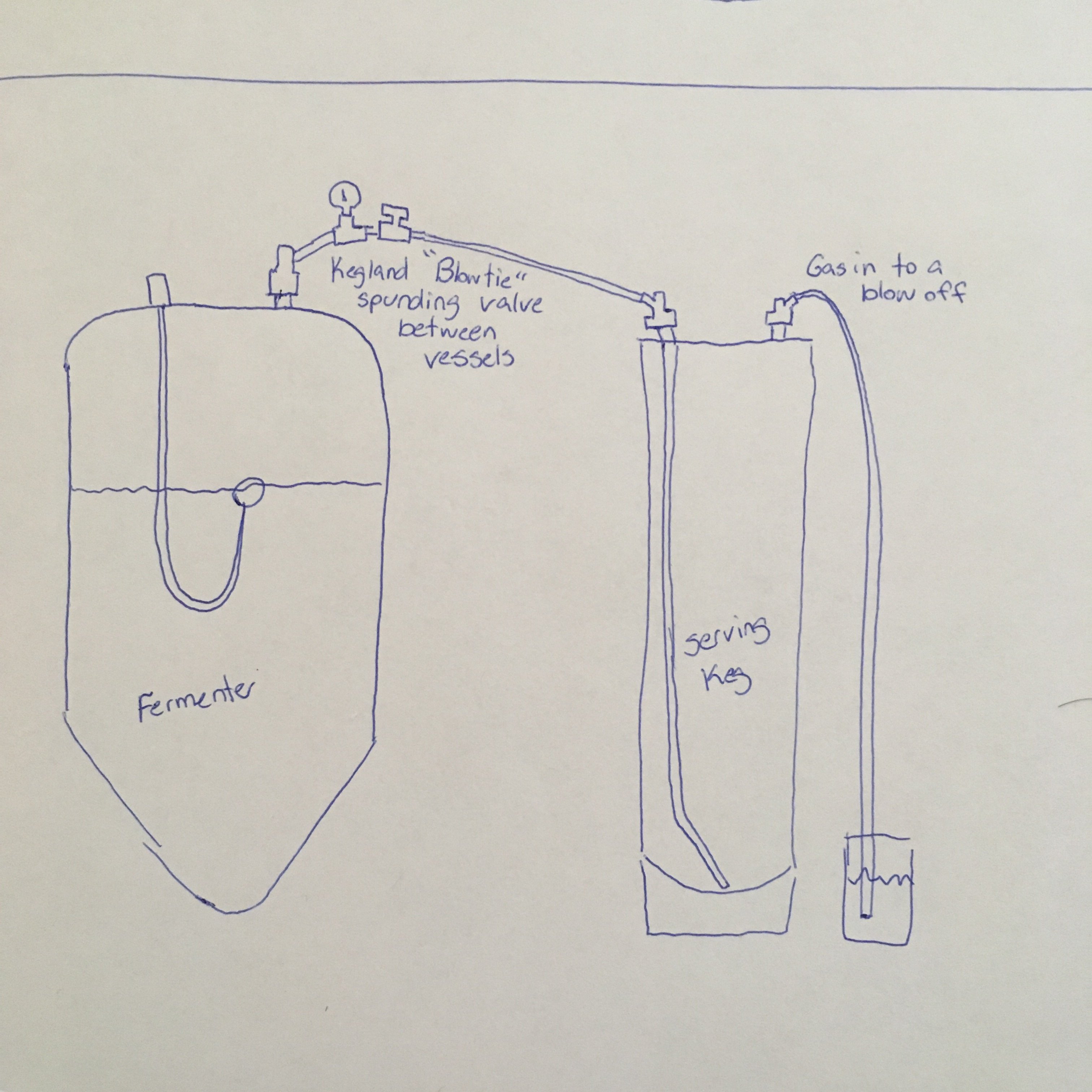

Option 2:

Use the kegland BlowTie spunding valve which allows tubing to be connected to the outlet. This way I can put the spunding setup directly on the fermenter and then route the gas that gets past the valve to purge the serving keg. A blow off tube or airlock would be needed on the serving keg but it would not be pressurized.

Pros:

The BlowTie is a diaphragm style valve so it’s supposed to be more accurate and shouldn’t leak.

Only the fermenter is being pressurized (I don’t know if that matters). With an airlock on the serving keg there is no chance of a leak causing o2 ingress.

Concerns:

Any possible blowoff going into the gauge and spunding valve.

I’m in Canada and the BlowTie and related parts are not available. I can order from MoreBeer and ship accross the border but obviously it’ll cost quite a bit more.

Just the need for an extra hose and container of sanitizer for an airlock.

So what say ye, wise brethren of the brew?

Option 1:

Jumper between the gas post of the fermenter to the liquid post of the serving keg. Put a typical spring and poppet style spunding valve on the gas post of the serving keg set to 5 psi and it’s ready to go

Pros:

No blow off liquid, airlock, or extra hose needed (less cleaning)

I can buy all the stuff at my LHBS

Concerns:

I’m concerned that 5 psi might not be enough to seal the lid which means the fermenter won’t get pressurized and krausen could get up in the jumper/serving keg.

I’ve heard that spring and poppet spunding valves tend to leak so I might have to keep a closer eye on this at the tail end of fermentation. I like to be pretty hands off and give plenty of time in primary 2 weeks plus so I’d rather not have to futz with it.

Option 2:

Use the kegland BlowTie spunding valve which allows tubing to be connected to the outlet. This way I can put the spunding setup directly on the fermenter and then route the gas that gets past the valve to purge the serving keg. A blow off tube or airlock would be needed on the serving keg but it would not be pressurized.

Pros:

The BlowTie is a diaphragm style valve so it’s supposed to be more accurate and shouldn’t leak.

Only the fermenter is being pressurized (I don’t know if that matters). With an airlock on the serving keg there is no chance of a leak causing o2 ingress.

Concerns:

Any possible blowoff going into the gauge and spunding valve.

I’m in Canada and the BlowTie and related parts are not available. I can order from MoreBeer and ship accross the border but obviously it’ll cost quite a bit more.

Just the need for an extra hose and container of sanitizer for an airlock.

So what say ye, wise brethren of the brew?