Hartwa

Member

Hi All...

This is my 1st post on this site.

I have been home brewing all grain for a couple of years. I have little difficulty brewing ales... I have tried a few lagers with no luck. They always seem to come out with low alcohol and really bitter.

I have given up on lagers for the most part..butI am thinking of trying one again. I hear that lagers are harder to get good fermentation so I have already tried the following things...

> Get O2 in the wort by shaking the fermentor and splashing the wort around...Lagers need more O2.

> Start the fermentation at a higher temp to get it going...

I have done these things with still poor results. I buy fresh yeast that comes in the bag that you punch for a starter....

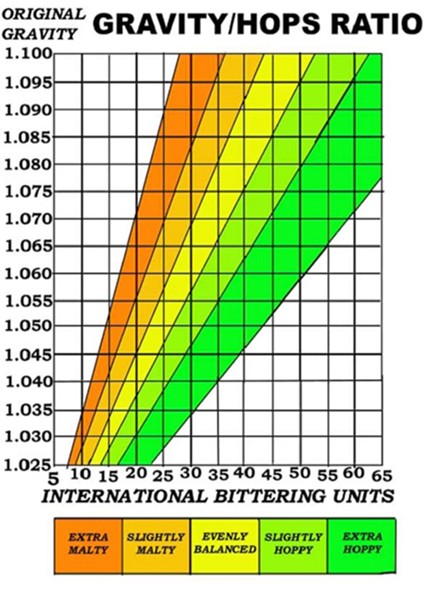

I appreciate any insight into what else I should be doing... I am most upset with the bitterness of the beer. I think that it is not from the hops...it just tastes like green beer that needs to sit for a long while. That makes me think that the lagers may not be something that is even drinkable in 3 months after brewing... Maybe this is an aging problem?

Apprecitate any help..

Hartwa

This is my 1st post on this site.

I have been home brewing all grain for a couple of years. I have little difficulty brewing ales... I have tried a few lagers with no luck. They always seem to come out with low alcohol and really bitter.

I have given up on lagers for the most part..butI am thinking of trying one again. I hear that lagers are harder to get good fermentation so I have already tried the following things...

> Get O2 in the wort by shaking the fermentor and splashing the wort around...Lagers need more O2.

> Start the fermentation at a higher temp to get it going...

I have done these things with still poor results. I buy fresh yeast that comes in the bag that you punch for a starter....

I appreciate any insight into what else I should be doing... I am most upset with the bitterness of the beer. I think that it is not from the hops...it just tastes like green beer that needs to sit for a long while. That makes me think that the lagers may not be something that is even drinkable in 3 months after brewing... Maybe this is an aging problem?

Apprecitate any help..

Hartwa