Sure. there are several variants of beer engine. I stuck with Angram as they are still in business and most bars you go into in the UK you will see the Angram logo on the front of the plinth. Parts and documentation are readily available. Beer Engines are available in 1/4 pint per pull and 1/2 pint. I strongly recommend for Homebrew, you use the 1/4pint which wastes less beer. The first ’pull’ will dispense beer that has been sitting in the beer engine’s cylinder. You throw that away if it’s been sitting there for more that an hour or so - 1/4 pint is a lot easier to throw away than 1/2 pint!

The other decision is where you want the beer engine’s cylinder to be cooled or not. For Homebrew use most will forgo this luxury. If you are pulling a pint, then thats four pulls (with a 1/4 pint model). The first pull will be warmer - close to room temp - and the other three will be at kegerator temperature - 39F. This results in a beer that is much closer to the recommended temperature for cask ales 50-55F.

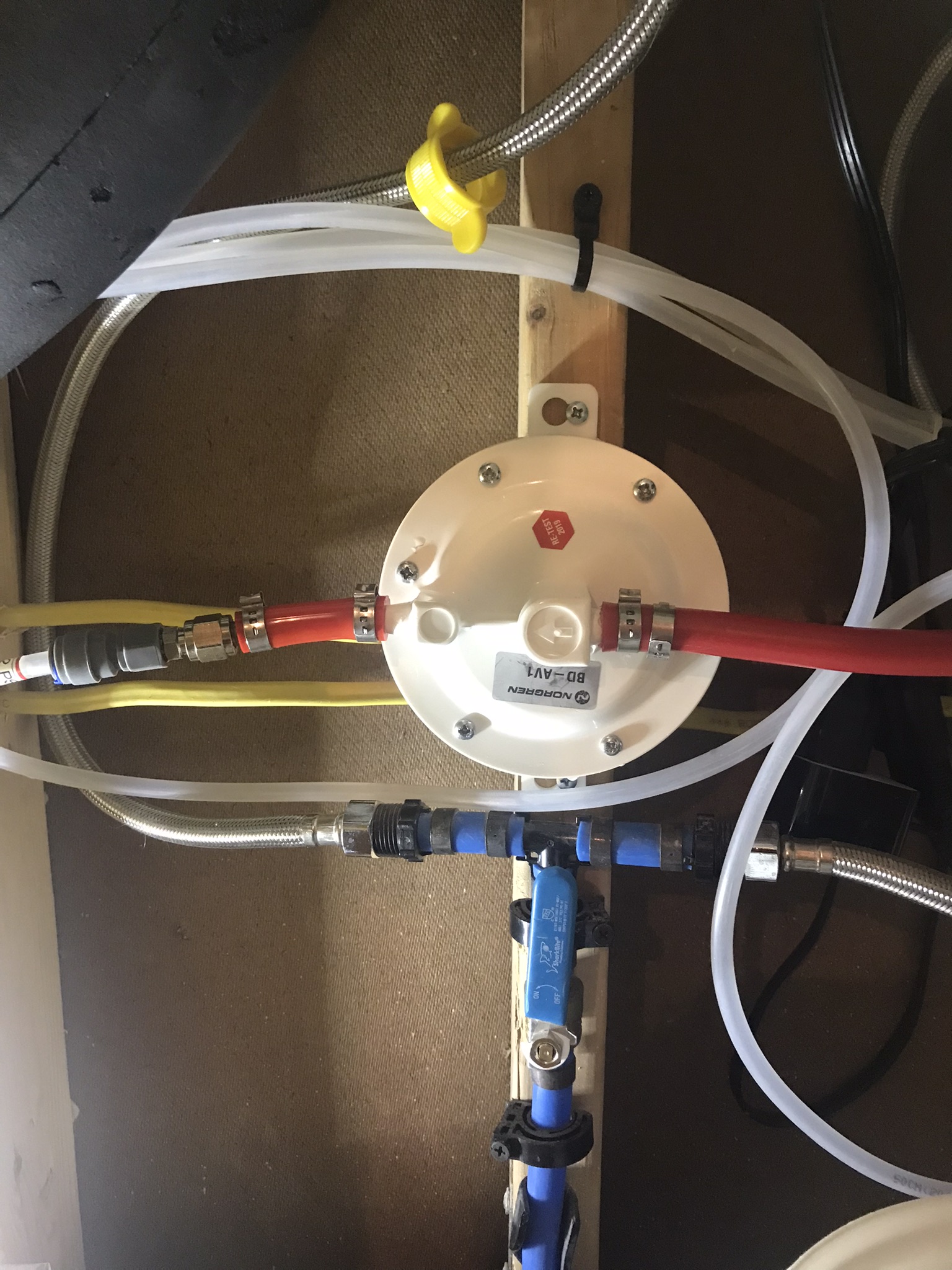

This is my setup:

View attachment 809053

There are two problems that have to be overcome when hooking up a beer engine (hand-pull) to a corny keg. The first one is that when beer is pulled out of the corny keg, CO2 at a low pressure needs to be admitted. This is what the demand valve is used for. The demand valve allows CO2 at around 2psi to flow into the keg but only when there is a lower pressure in the keg. This is not the same as just dialing the regulator down to 2psi. If you do this, then the beer will have 2psi on it all the time and eventually become carbonated.

the best illustration of how the demand valve works is when I first hooked it up to the CO2 regulator and had no hose on the ‘out’ side. I put my finger over it and sniffed it expecting there to be CO2 coming out and it wasn’t. I then sucked on the outlet tube and immediately got a mouthful of CO2! It needs that negative pressure for the demand valve to turn on.

This is the demand valve:

View attachment 809048

The next problem is that you have to prevent beer from the beer engine from draining back into the keg and any pressure in the keg forcing beer out the beer engine. This is what the check valve does. They are available with or without an over-ride lever that is used to disable the one way function for beer line cleaning. This should be mounted right behind the hand-pull.

This is the check valve:

View attachment 809049

I paid $18 for this direct from England.

Resources:

1) Paul Pendyck who runs uk brewing.com is a mine of information with videos on his site and YouTube describing what you have to do to set up a beer engine. His sire also has all the supplies you need. My previously owned beer engine needed a new piston and seal and Paul was able to provide this quickly.

2) In the UK, RLBS is the big elephant in the cage. I have bought from them directly although I think their minimum is $60. I bought a couple of extra parts and sold them on this forum which worked well. Shipping is reasonable.

Let me know if you need help,

Paul