AlfA01

...it ain't sold in heaven...

Cheers Everyone,

My wife and I have recently (by way of inheritance, lawyers and court) come into a hotel on the Greek island of Evia. The place needs a lot of work and money, but since we're masochistic enough to take it on, we're setting off to try our hand in the tourism business.

With that out of the way, on to the brewing stuff. We have it in our minds to brew and give complimentary beers to our guests initially. After some time, we will see if it takes off and move to another level of brewing. For now, we're keeping it 'homebrew' style and small scale.

The planned brew rig:

An 'All-In-One' similar to the 200 liter Spiedel Braumeister.

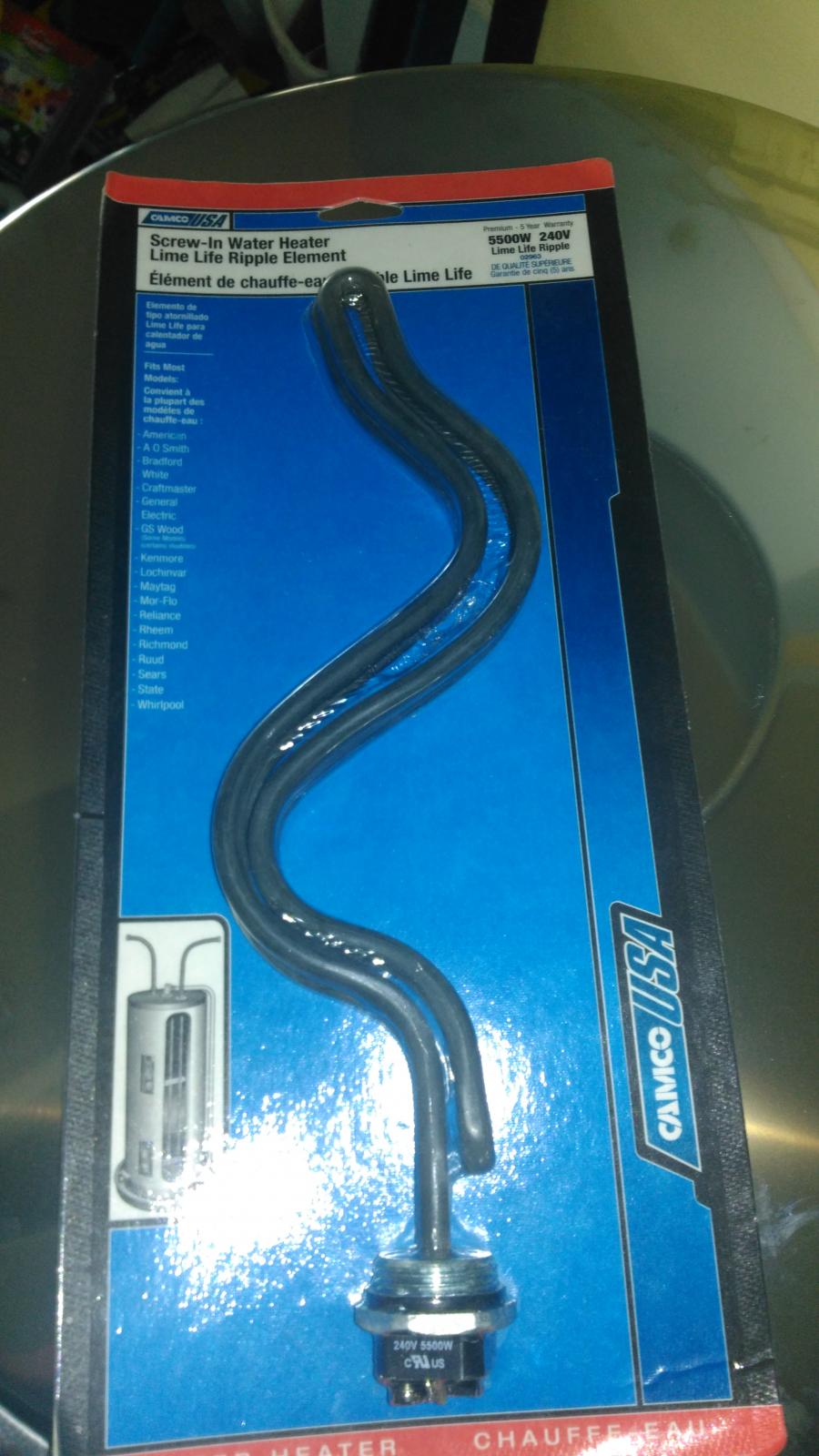

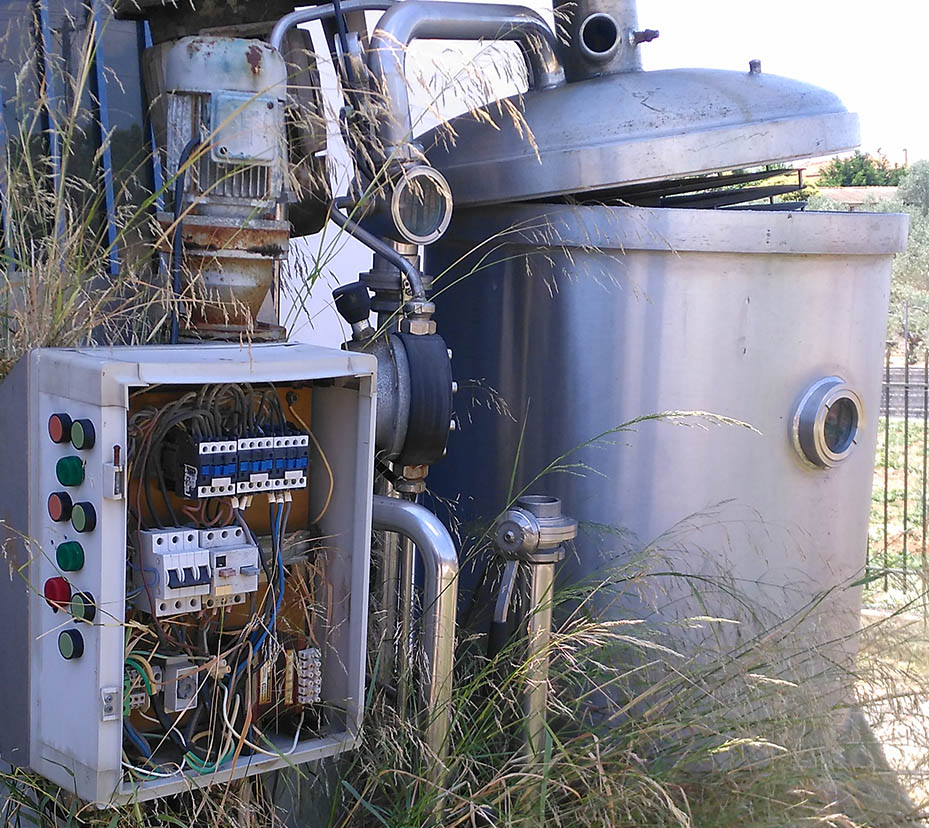

So far, we have a 200 liter stainless tank, control box (electric setup), two 5500 watt elements, 4500 watt element (on order), three PIDs, control panel lights, switches, circuit breakers, and sanitary tri-clamp fittings to setup the plumbing.

A 70 liter brew kettle will be sacrificed to become the malt pipe (grain basket). I plan to chop the bottom out of the kettle, while leaving a lip to hold inserts similar to a false bottom. The system should work like a BIAB, while offering the convenience and sustainability of stainless steel. :rockin:

My initial idea is to reverse sparge or make a constant Vorlauf during the lautering phase--meaning, the pump will take the wort from a bottom drain located outside of the malt pipe and slowly pump it back through the center bottom drain which is inside of the malt pipe. A piece of perforated stainless steel tubing would disperse to the wort through the lautering grains to extract as much convertible sugars as possible potentially give a very thorough grain wash.

Currently, the first design issue is establishing a variable speed for the pump. During lautering I would like the pump to run at very low RPM to simply circulate the wort through the malt pipe.

The second problem is that I will have two 5500W elements in the kettle. The 4500W I mentioned above will be a RIMS style, where the pump will circulate the strike water prior to adding grains in order to decrease 'time-to-boil' times. 180 liters of 13C water with 11000W takes approximately 90 minutes to boil By adding the third element, I can reduce the time-to-boil to 60 minutes.

By adding the third element, I can reduce the time-to-boil to 60 minutes.  My question is what setup should I use. I'm planning to use all stainless tri-clamp sanitary fittings. I could in corporate two reducers and straight pipe that would house the third element (4500W), which would only fire during strike water heating and maybe during the boil (depending on my test results after the build).

My question is what setup should I use. I'm planning to use all stainless tri-clamp sanitary fittings. I could in corporate two reducers and straight pipe that would house the third element (4500W), which would only fire during strike water heating and maybe during the boil (depending on my test results after the build).

That's it for now. I've ordered Kal's Electric Brewery build .pdf in order to setup my control panel. The Internet is really slow for me at the moment, as I only have a really low signal on 3G, so uploading photos is a pain. I will try to get some pics uploaded soon so everyone can have a look at what I've got at the moment.

Cheers and I look forward to the replies.

Dan

My wife and I have recently (by way of inheritance, lawyers and court) come into a hotel on the Greek island of Evia. The place needs a lot of work and money, but since we're masochistic enough to take it on, we're setting off to try our hand in the tourism business.

With that out of the way, on to the brewing stuff. We have it in our minds to brew and give complimentary beers to our guests initially. After some time, we will see if it takes off and move to another level of brewing. For now, we're keeping it 'homebrew' style and small scale.

The planned brew rig:

An 'All-In-One' similar to the 200 liter Spiedel Braumeister.

So far, we have a 200 liter stainless tank, control box (electric setup), two 5500 watt elements, 4500 watt element (on order), three PIDs, control panel lights, switches, circuit breakers, and sanitary tri-clamp fittings to setup the plumbing.

A 70 liter brew kettle will be sacrificed to become the malt pipe (grain basket). I plan to chop the bottom out of the kettle, while leaving a lip to hold inserts similar to a false bottom. The system should work like a BIAB, while offering the convenience and sustainability of stainless steel. :rockin:

My initial idea is to reverse sparge or make a constant Vorlauf during the lautering phase--meaning, the pump will take the wort from a bottom drain located outside of the malt pipe and slowly pump it back through the center bottom drain which is inside of the malt pipe. A piece of perforated stainless steel tubing would disperse to the wort through the lautering grains to extract as much convertible sugars as possible potentially give a very thorough grain wash.

Currently, the first design issue is establishing a variable speed for the pump. During lautering I would like the pump to run at very low RPM to simply circulate the wort through the malt pipe.

The second problem is that I will have two 5500W elements in the kettle. The 4500W I mentioned above will be a RIMS style, where the pump will circulate the strike water prior to adding grains in order to decrease 'time-to-boil' times. 180 liters of 13C water with 11000W takes approximately 90 minutes to boil

My question is what setup should I use. I'm planning to use all stainless tri-clamp sanitary fittings. I could in corporate two reducers and straight pipe that would house the third element (4500W), which would only fire during strike water heating and maybe during the boil (depending on my test results after the build).

My question is what setup should I use. I'm planning to use all stainless tri-clamp sanitary fittings. I could in corporate two reducers and straight pipe that would house the third element (4500W), which would only fire during strike water heating and maybe during the boil (depending on my test results after the build). That's it for now. I've ordered Kal's Electric Brewery build .pdf in order to setup my control panel. The Internet is really slow for me at the moment, as I only have a really low signal on 3G, so uploading photos is a pain. I will try to get some pics uploaded soon so everyone can have a look at what I've got at the moment.

Cheers and I look forward to the replies.

Dan

Last edited: