daphatgrant

Well-Known Member

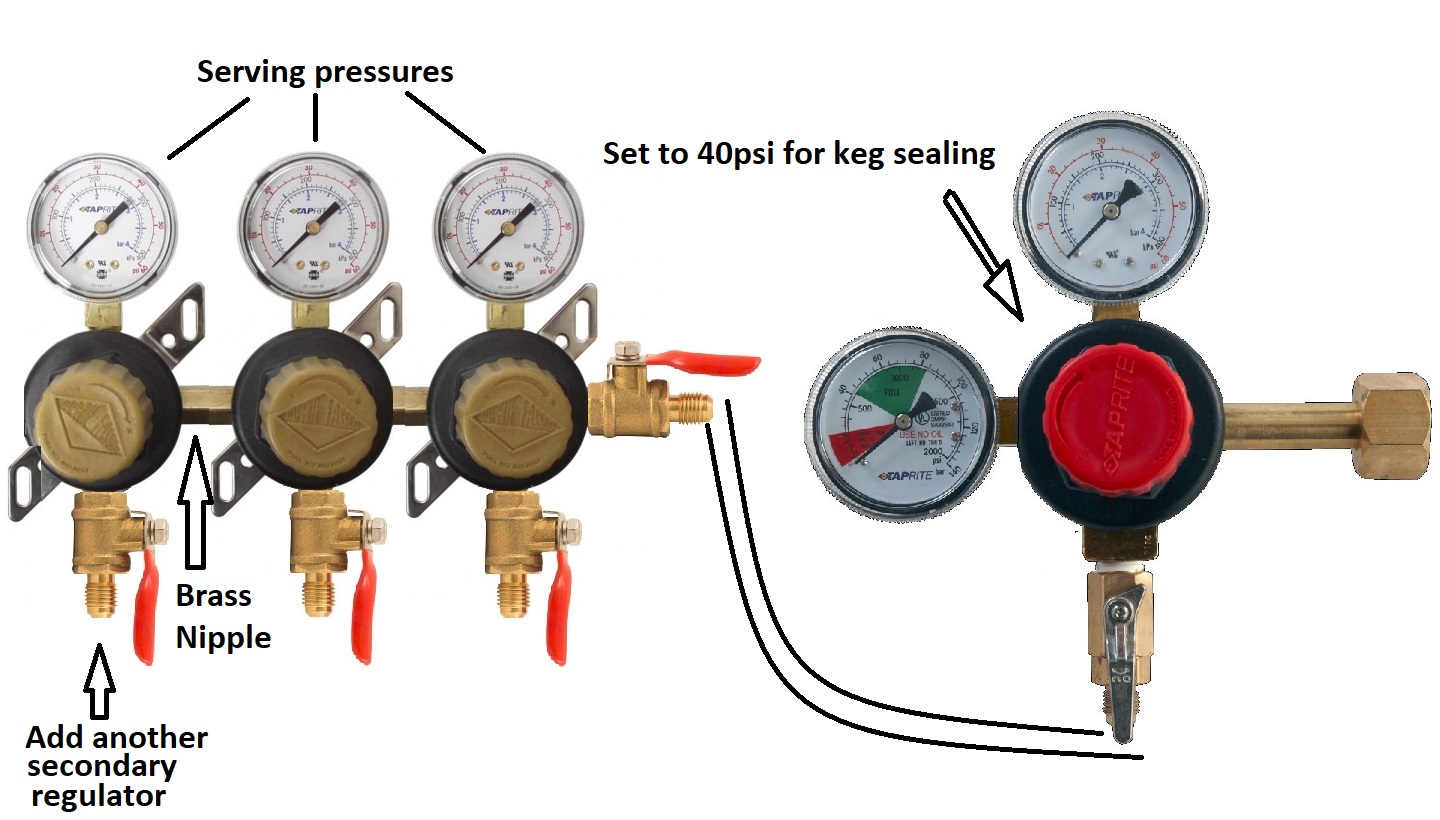

So, I thought that this would be easy, ha. I have a Taprite dual gauge regulator that I was hooking to a 3-way distributor to go to my 3 kegs. I'd like to start kegging things other than beer along with my beer. I did some research and thought that adding a secondary regulator would be perfect. I figured I could keep using my dual gauge regulator, remove the high pressure gauge and place it on secondary regulator, add a 1/4"npt tp 1/4" mfl, throw some hose in there and be happy. I even made up some nice diagrams before hand. Well tonight I went to put everything together and the the high pressure gauge is left hand threaded...

So... I've been meaning to buy another regulator for my 20# "utility" tank that I use for purging kegs and the occasional unsuccessful force carbing. Should I buy another dual gauge regulator that has right hand thread gauges and do what I had intended originally? Or should I use the dual gauge regulator I have and buy a high pressure right hand thread gauge and a left hand thread shut-off with check valve (if they exist)?

Here's are the regulators that I currently have and the shut-offs.

Primary - https://www.midwestsupplies.com/taprite-co2-regulator-with-1-4-mfl

Secondary - https://www.morebeer.com/products/secondary-regulator-2.html?site_id=7#

Replacement Shut-offs - https://www.morebeer.com/products/shutoff-valve-14-mpt-mfl.html

Original plans:

So... I've been meaning to buy another regulator for my 20# "utility" tank that I use for purging kegs and the occasional unsuccessful force carbing. Should I buy another dual gauge regulator that has right hand thread gauges and do what I had intended originally? Or should I use the dual gauge regulator I have and buy a high pressure right hand thread gauge and a left hand thread shut-off with check valve (if they exist)?

Here's are the regulators that I currently have and the shut-offs.

Primary - https://www.midwestsupplies.com/taprite-co2-regulator-with-1-4-mfl

Secondary - https://www.morebeer.com/products/secondary-regulator-2.html?site_id=7#

Replacement Shut-offs - https://www.morebeer.com/products/shutoff-valve-14-mpt-mfl.html

Original plans: