I have been reading the DIY forum and digesting the plethora of information contained in the forum for a few months. I feel I need to give the obligatory "Thank You" to everyone on this forum. If it was not for the generosity and wealth of knowledge shared on the forum I would not of been able to start this project.

After jealously watching and reading thread after thread of "Check out my HERMS" In November I finally decided to build my own. I created some plans using SketchUp and started a parts lists.

An old friend from school is a metal fabricator and after a few home brews he agreed to do most of the metal fab work. As long as I pay for materials and kep him supply of good home brew.

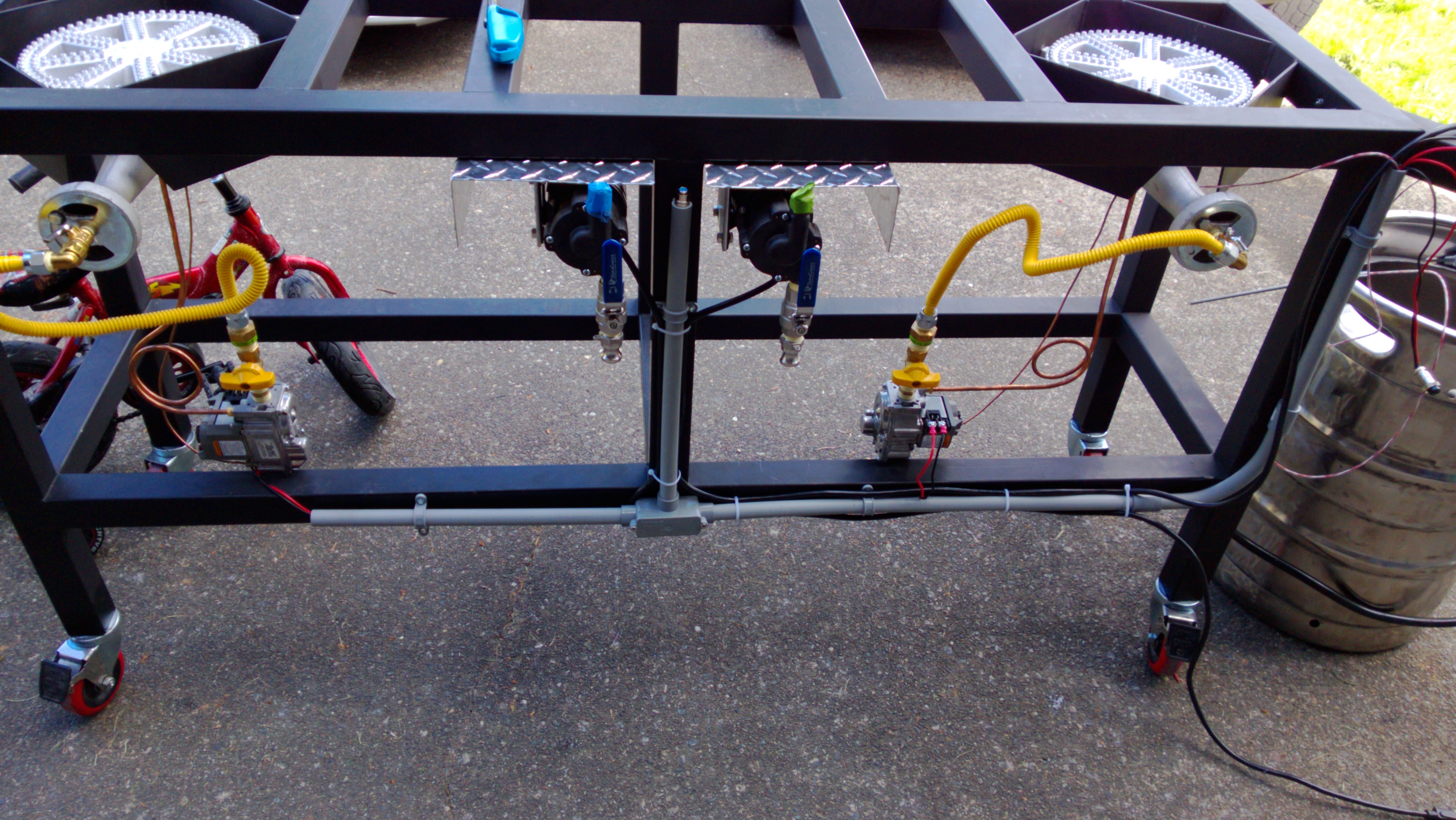

We completed the base on Thursday

Brought it to my house on Friday for painting and installing the gas system.

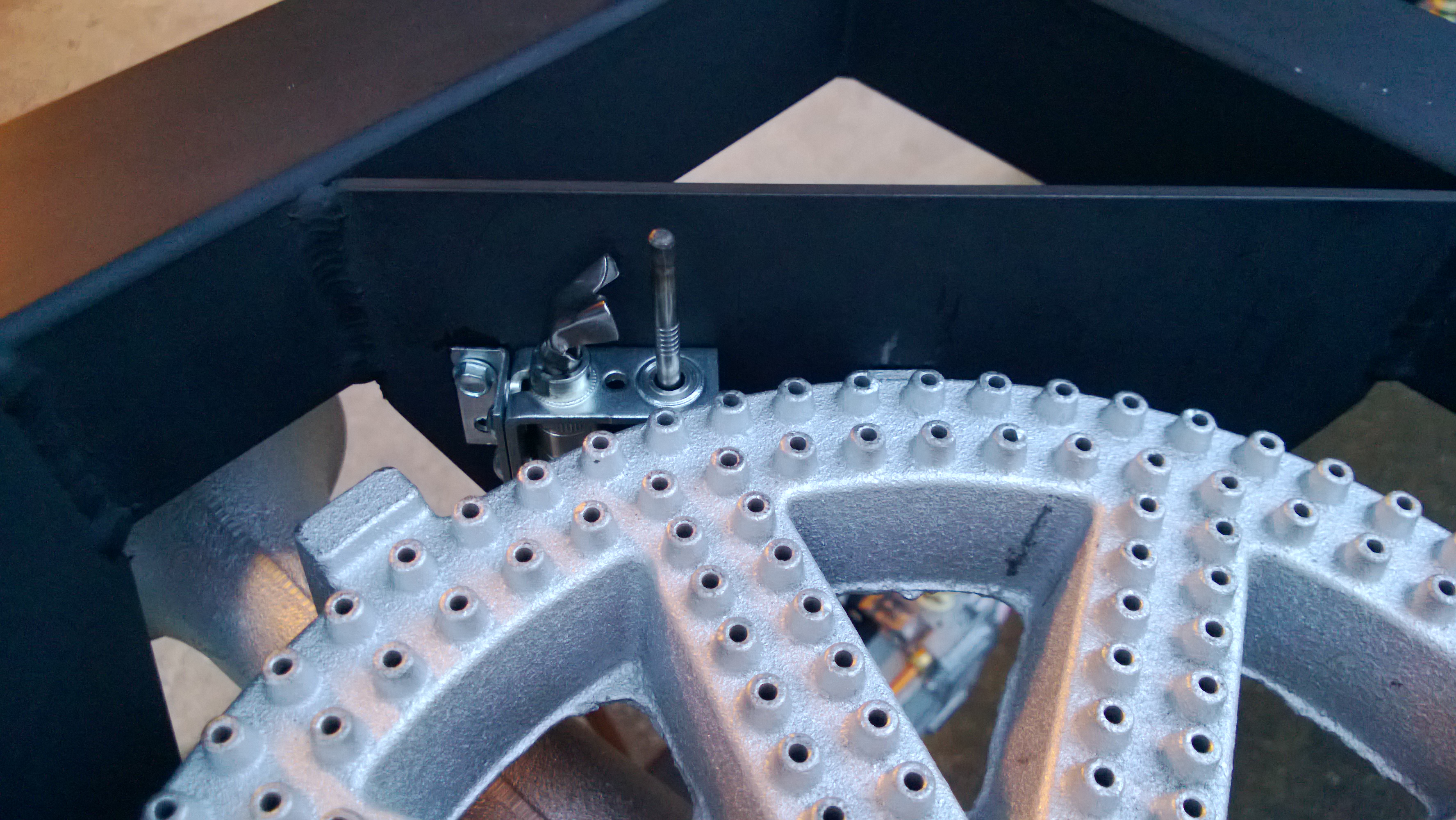

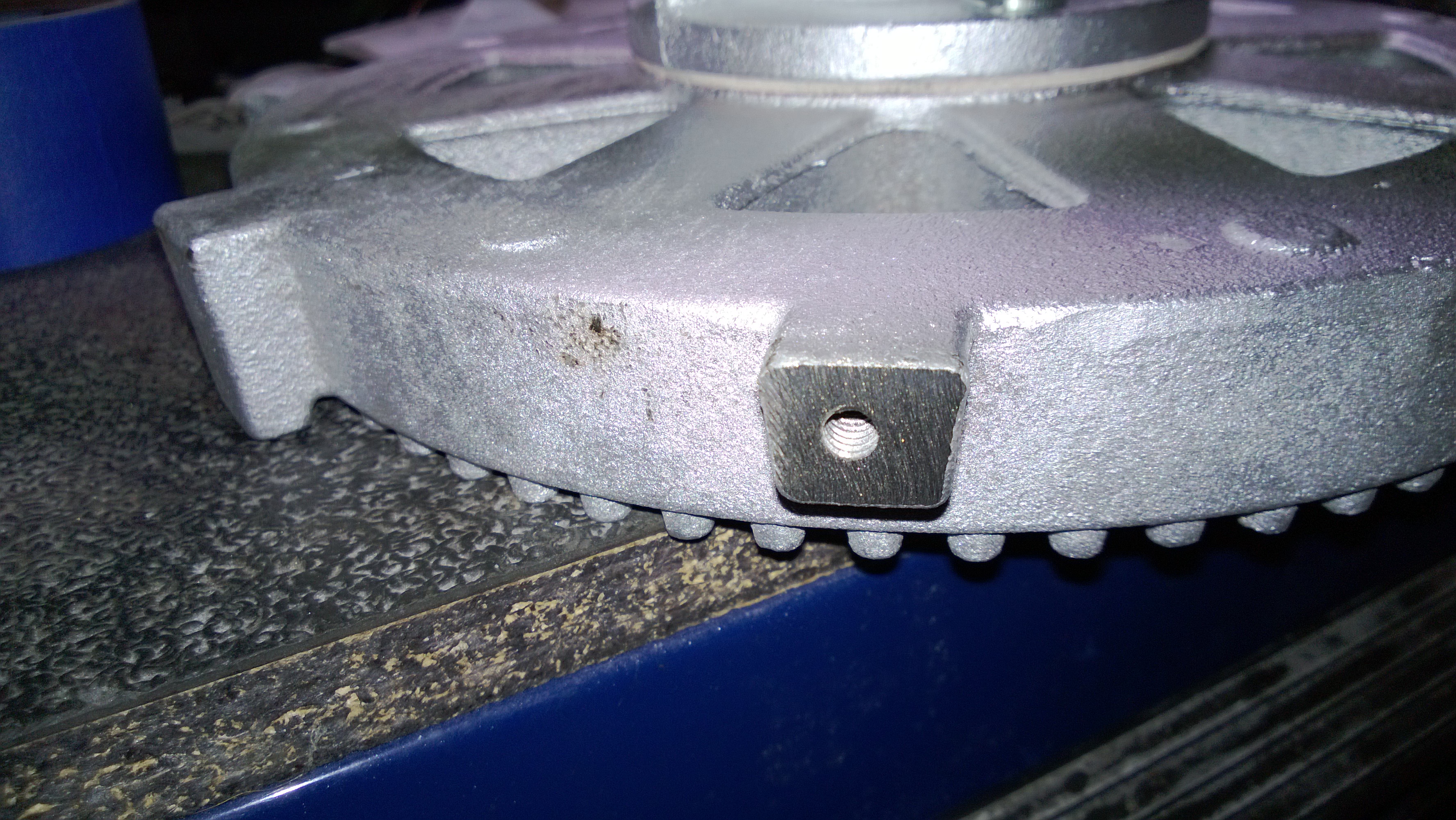

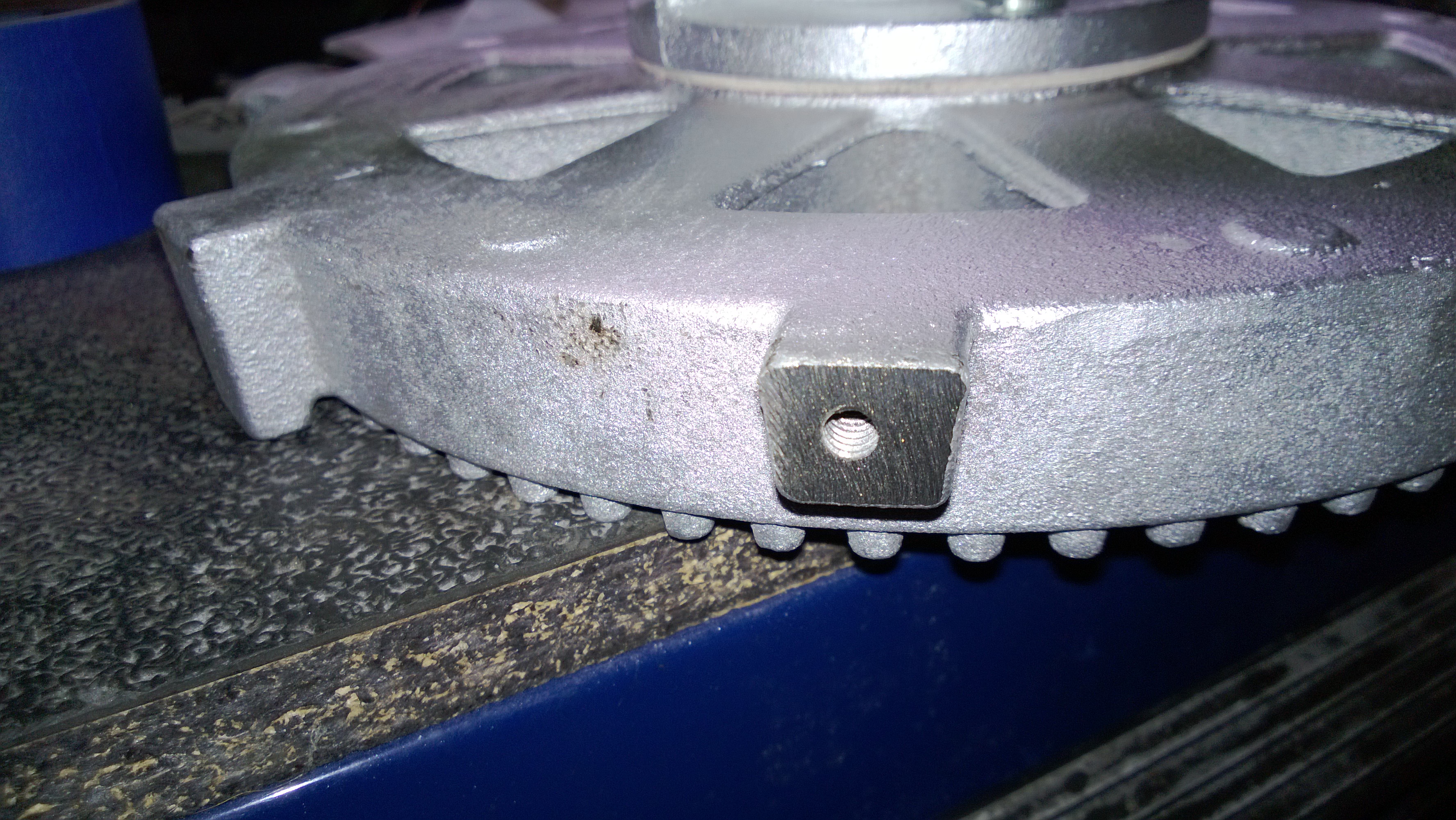

needed to adjust the burner mounts a little.

I would suggest anyone building a stand similar with the BG-14 bruners. Give yourself about 11 1/8 cleaners for the burners.

EDIT: Another tip - if you can make the holes for the burners mounts rectangles. not all of the screw holes line up.

Next up...

Gas parts are on order from PEX Supply and will be here next thursday.

The stand will be painted on Wednesday.

The control arm will be completed and bolted on next Saturday.

Can't wait to get this bad boy up and running!

After jealously watching and reading thread after thread of "Check out my HERMS" In November I finally decided to build my own. I created some plans using SketchUp and started a parts lists.

An old friend from school is a metal fabricator and after a few home brews he agreed to do most of the metal fab work. As long as I pay for materials and kep him supply of good home brew.

We completed the base on Thursday

Brought it to my house on Friday for painting and installing the gas system.

needed to adjust the burner mounts a little.

I would suggest anyone building a stand similar with the BG-14 bruners. Give yourself about 11 1/8 cleaners for the burners.

EDIT: Another tip - if you can make the holes for the burners mounts rectangles. not all of the screw holes line up.

Next up...

Gas parts are on order from PEX Supply and will be here next thursday.

The stand will be painted on Wednesday.

The control arm will be completed and bolted on next Saturday.

Can't wait to get this bad boy up and running!