snowtires

Well-Known Member

- Joined

- Sep 7, 2012

- Messages

- 621

- Reaction score

- 92

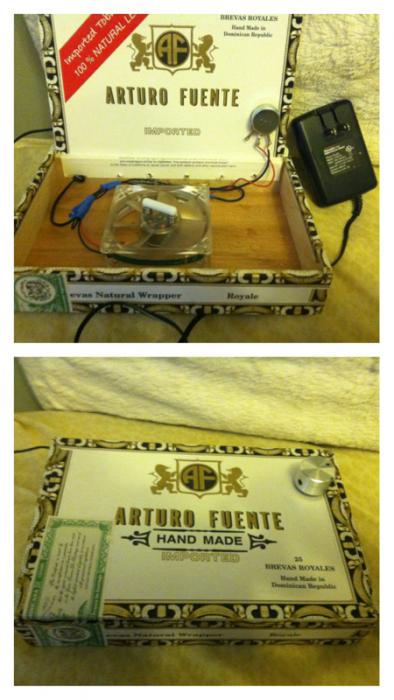

Hi im working on a stir plate build and looking around for items i have around the house i found a pair of computer speakers so i got the volume control knob off it but I dont even know if it would work for a stir plate. I have found it online but dont know how i would wire it up. So if anyone out there knows if this would work and how, that would be much appreciated.

http://www.alibaba.com/product-gs/346285679/16mm_DIP_Rotary_potentiometer_with_switch.html

http://www.alibaba.com/product-gs/346285679/16mm_DIP_Rotary_potentiometer_with_switch.html