Stymingersfink

Member

- Joined

- Sep 21, 2017

- Messages

- 8

- Reaction score

- 2

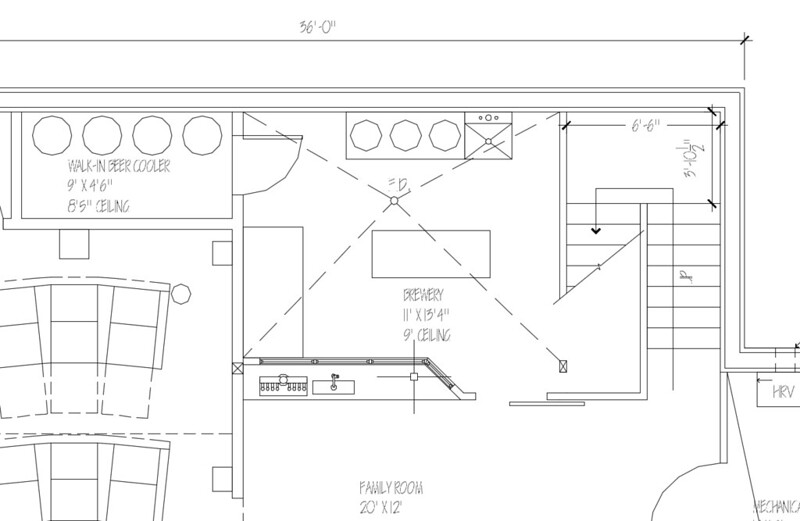

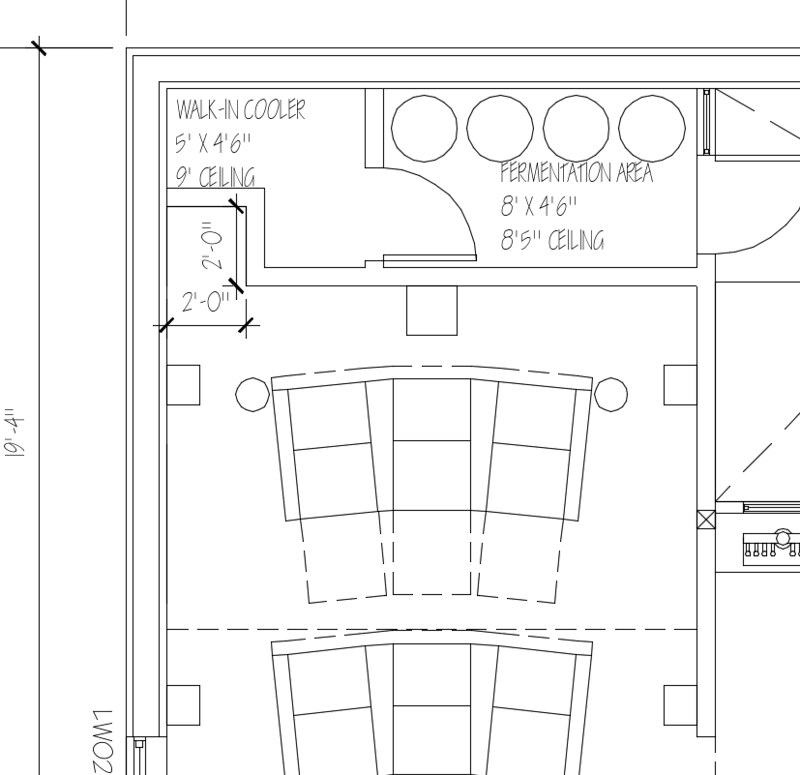

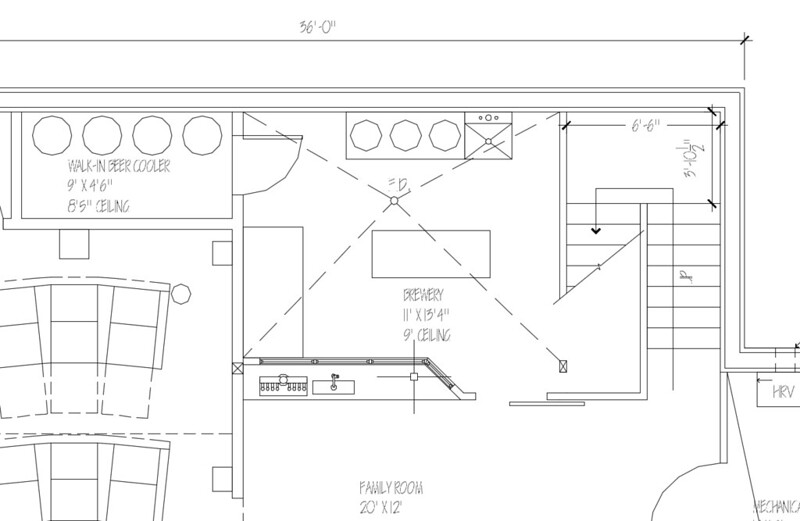

I am in the process of designing and building a new house which will be complete with a brewery in the basement. I have a small (4'6"x9'0") storage area off the brewery that I could turn into a walk-in beer cooler. I will be upping my game with this berewery and getting some conical fermenters. So my question is:

Is it better and more efficient to have an entire room that is refrigerated for the purposes of keeping the serving kegs cold as well as layering, Or is it better to use a keezer for serving and use a glycol chiller and coil in the fermenter for the fermentation process?

Any advice is appreciated. Here is a plan of the brewery so you can see the layout. The cooler is drawn with (4) 20 gallon conicals in it.

Is it better and more efficient to have an entire room that is refrigerated for the purposes of keeping the serving kegs cold as well as layering, Or is it better to use a keezer for serving and use a glycol chiller and coil in the fermenter for the fermentation process?

Any advice is appreciated. Here is a plan of the brewery so you can see the layout. The cooler is drawn with (4) 20 gallon conicals in it.