Brewpastor

Beer, not rocket chemistry

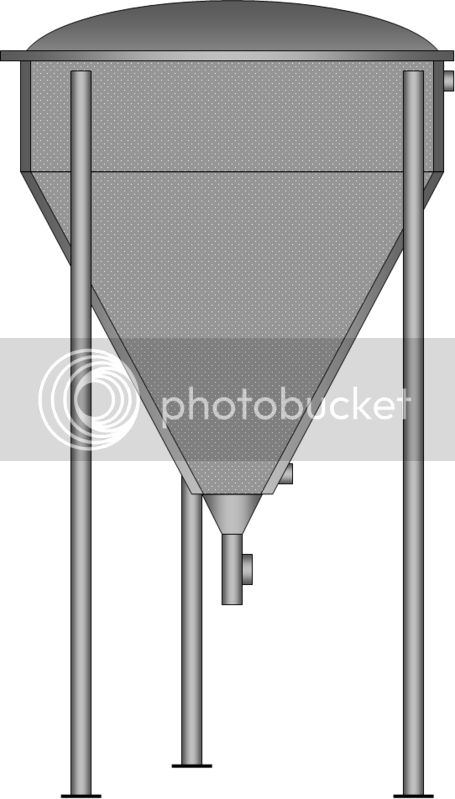

Here are my plans for The Pastorizer jacketed conical fermenter.

I have been threatening to do this for 3 years and I think the time has come!

I have two slightly different size hoppers from Toledo Metal Spinning. One hopper nests in the other with about a 1/4" space between. I will have the bottom of the outer jacket cut a few inches up from the bottom of the inner cone and sealed with a welded ring/plate to the inner cone at that point. 1" inlet and outlet ports will be welded to the outer jacket and the top lips of the hoppers (which have been cut by Toledo Metal Spinning to be the same OD) will be welded together.

I have been threatening to do this for 3 years and I think the time has come!

I have two slightly different size hoppers from Toledo Metal Spinning. One hopper nests in the other with about a 1/4" space between. I will have the bottom of the outer jacket cut a few inches up from the bottom of the inner cone and sealed with a welded ring/plate to the inner cone at that point. 1" inlet and outlet ports will be welded to the outer jacket and the top lips of the hoppers (which have been cut by Toledo Metal Spinning to be the same OD) will be welded together.