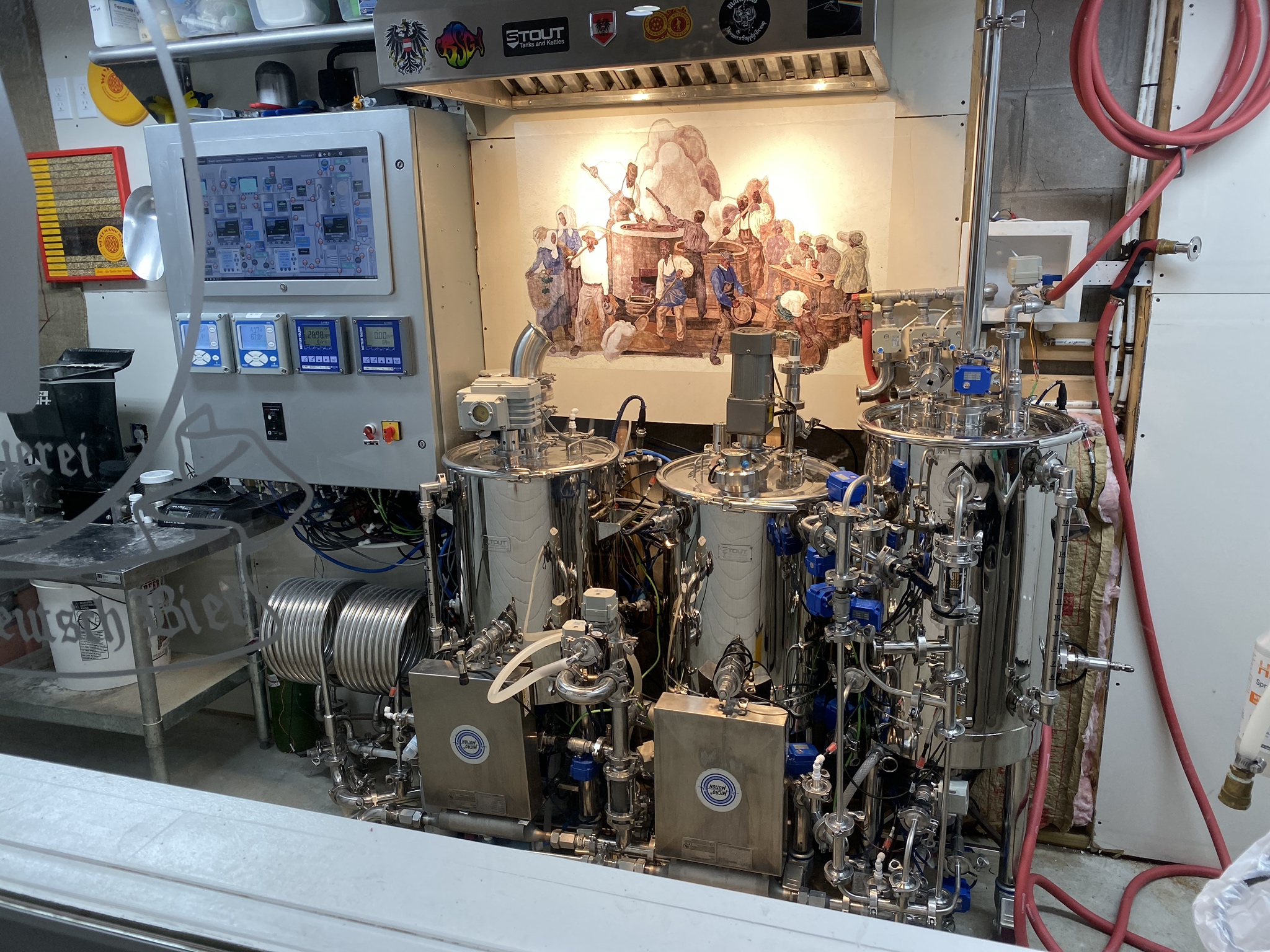

I have a three vessel RIMS system and just picked up an interesting kettle that was able to pressurize to transfer the boiled wort into the fermentor.

When I'm done boiling I run the boiled wort through a counterflow chiller....I let it recirculate in the BK so the cold break precipitates out. I use a Riptide pump to pump the wort into the fermenter.

Is there an advantage to using pressure? Is the pressure that of CO2, and the goal is to eliminate O2 pickup as you go from BK to fermenter?

I'm not sure it would matter much--we need to oxygenate the wort anyway if we used a starter, so it's not clear how much difference that makes.

If using dry yeast....maybe. You don't generally have to oxygenate the wort if using dry yeast. I don't know how much of the headspace above the wort in a BK could actually be replaced with CO2, though you could clearly knock down the amount of O2 occupying that space.

I don't know if im going to use it for my BK as I'm pretty happy with my current BK... But what about as a mash tun. once you have boiled off all the O2 in the HLT and started recirculating LODO strike water wouldn't a co2 purged sealed Mash tun virtually eliminate any risk of O2 effecting the wort?

I've given thought to the same thing from a different angle--I use a stainless kettle lid as a mash cap but it doesn't cover all the surface, just about maybe 85 or 90 percent. I've wondered about things like slowly bleeding CO2 into the headspace of the mash tun (same kind of idea, more or less), to eliminate intake of O2 into the mash.

If yours was enclosed, you could theoretically purge the headspace.....

<thinking out loud ON> One reason I use campden tablets (crushed) in my strike water after pre-boiling is to act as an oxygen scavenger during the mash. That's to offset my imperfect mash cap. I'm wondering just how much O2 uptake there is during the mash. The wort coming out of the mash tun is much more flavorful than w/o LODO concern, so I know what I'm doing is working....at least to some extent.

Wondering how much gain I could have if I could completely isolate the mash from the atmospheric O2.....

<still thinking> Along the same lines, after I add the crushed grain to the MT but before I begin underletting, I hit that mash tun with 30-60 seconds of CO2 through the valve and sight glass, trying to purge that MT from the bottom up. Then when the strike water is going in, the theory is the water pushes the CO2 up through the grain as it rises, ending up with a MT headspace of more CO2 than would otherwise be the case.

And I thought my setup looked complicated. Holy cow! Would you give us a detailed explanation of what's going on there?