WesP

Active Member

So I decided to get into some serious kegging with my latest purchase of six Sankey 1/4 BBL tall kegs. Since I don't want to deal with pulling out the spears every time I want to clean them, I'm building a cleaning station to make my life a lot easier.

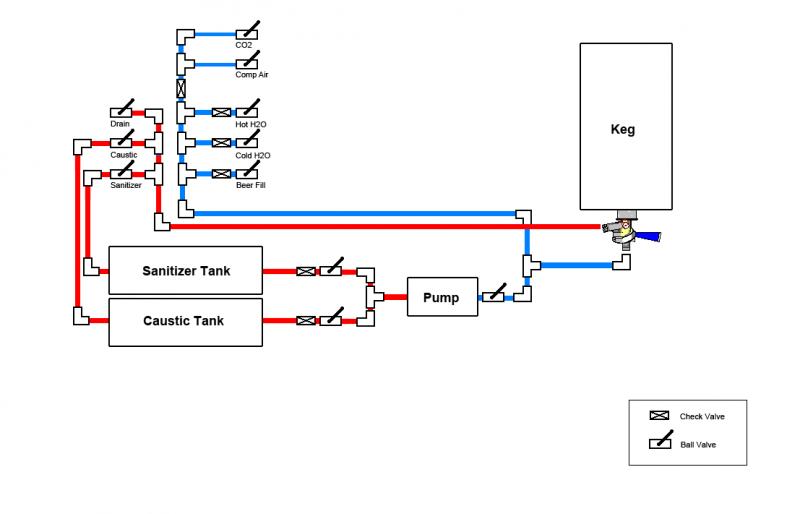

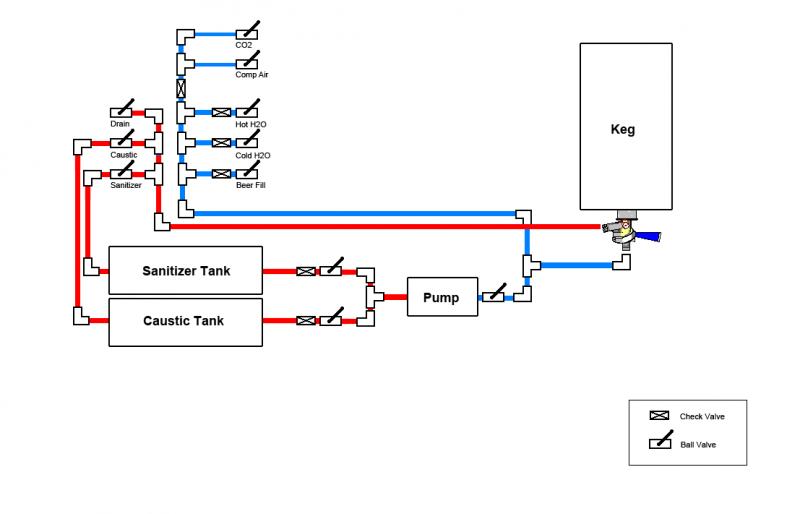

I wanted to get some feedback on my schematic for a sankey keg cleaning station that i'm planning on building in the next few weeks. It's a manual system which allows for 2 cleaning agents such as a caustic and sanitizer.

Let me know your thoughts!

-Wes

I wanted to get some feedback on my schematic for a sankey keg cleaning station that i'm planning on building in the next few weeks. It's a manual system which allows for 2 cleaning agents such as a caustic and sanitizer.

Let me know your thoughts!

-Wes