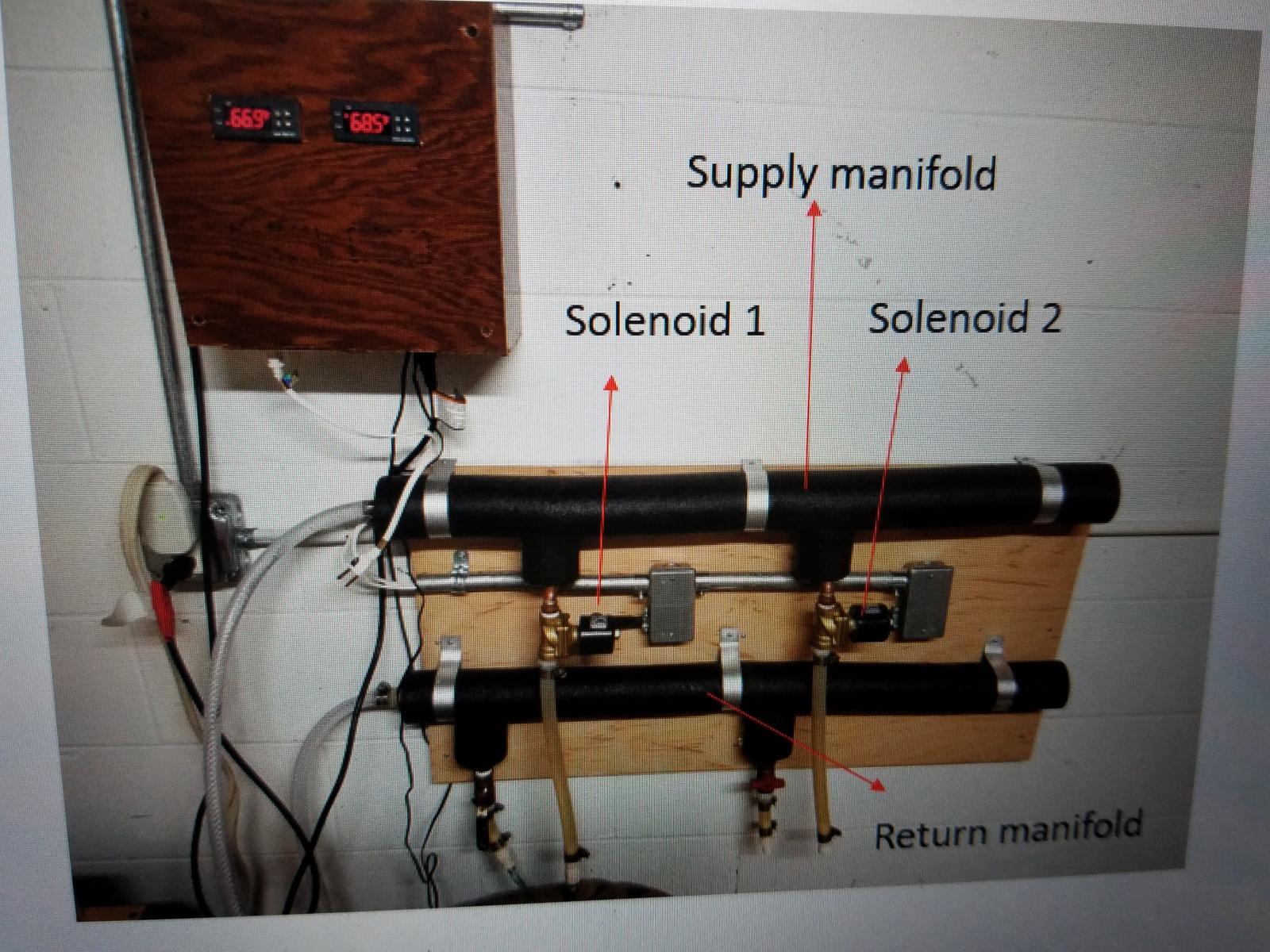

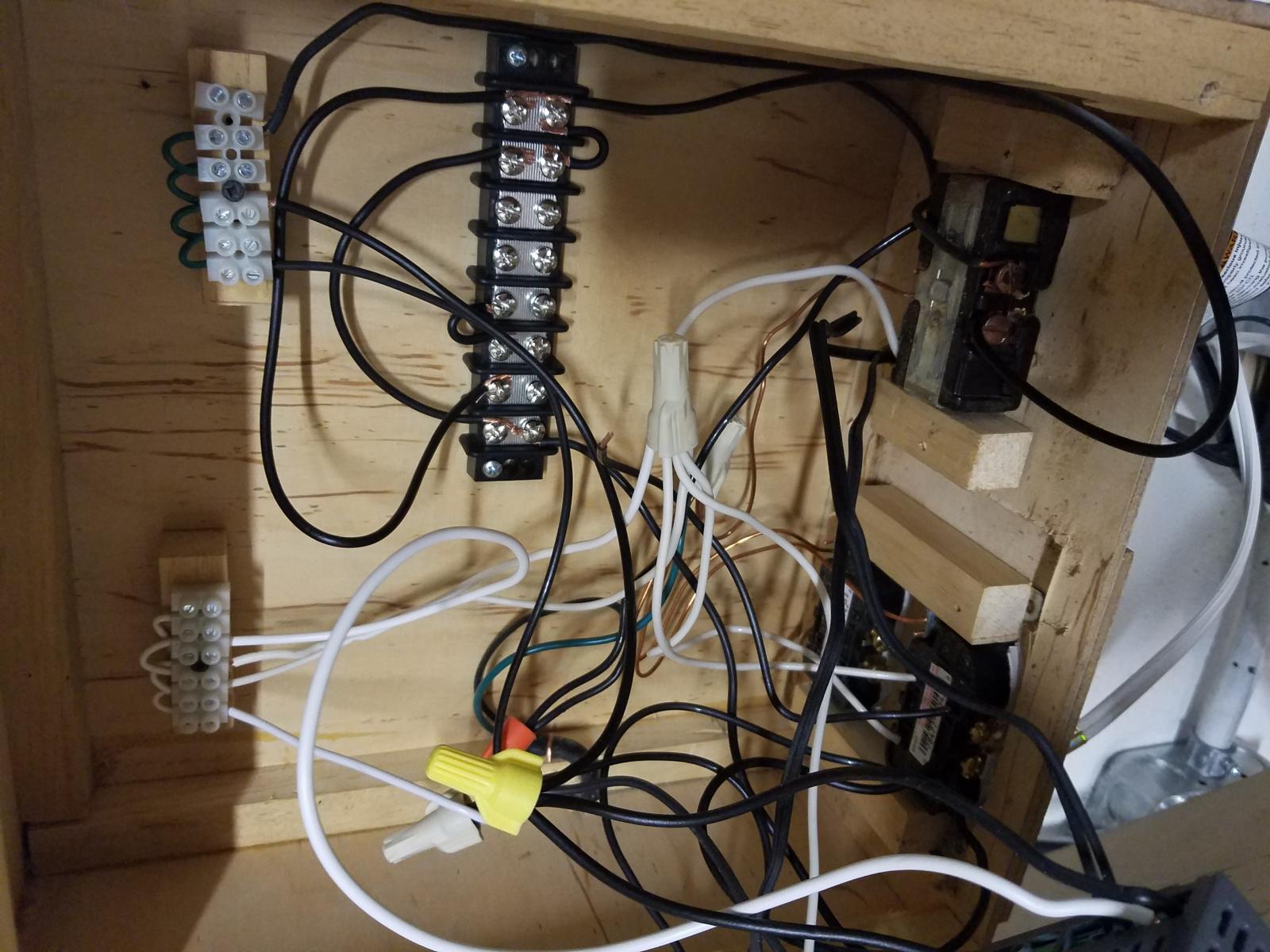

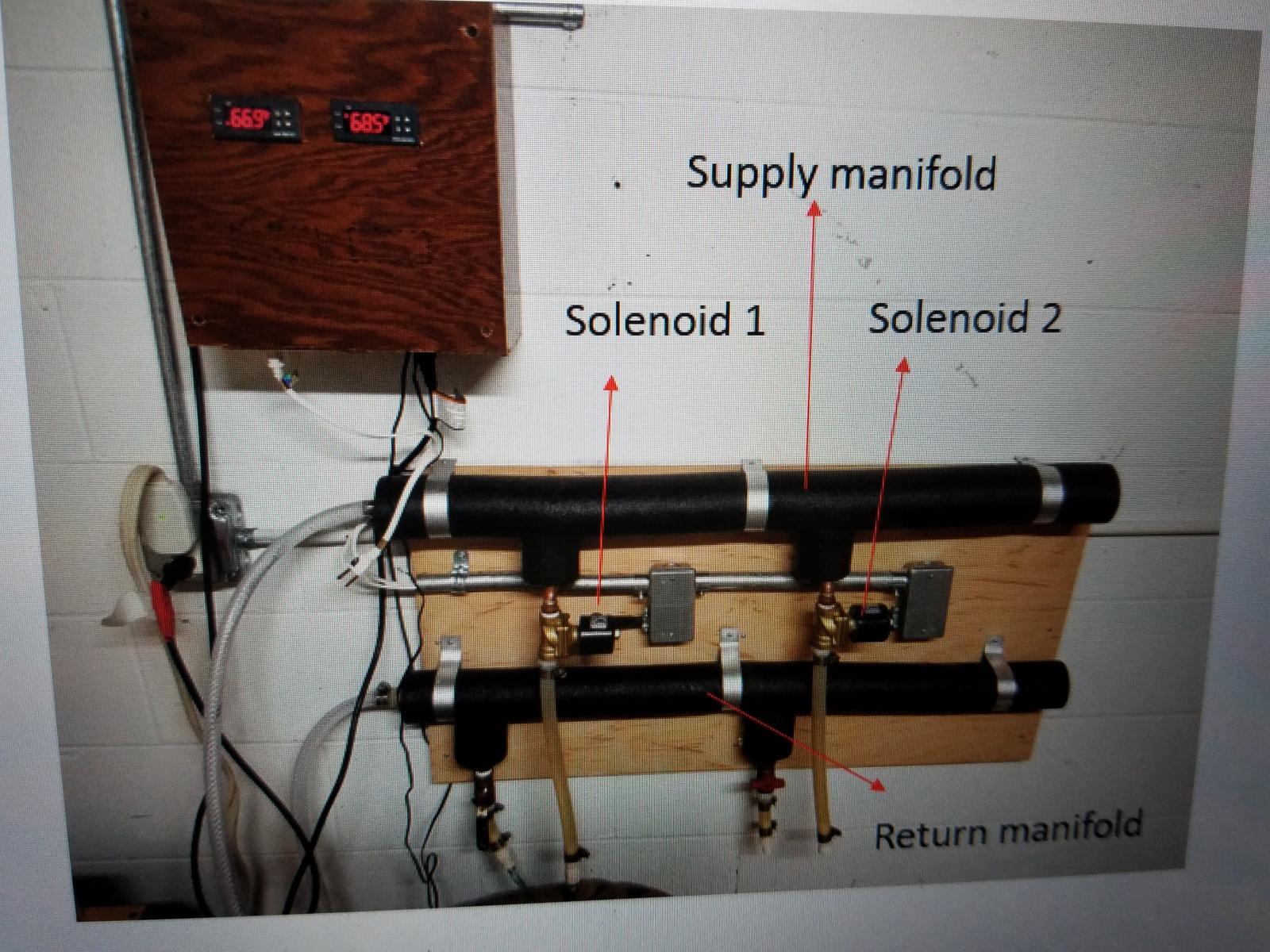

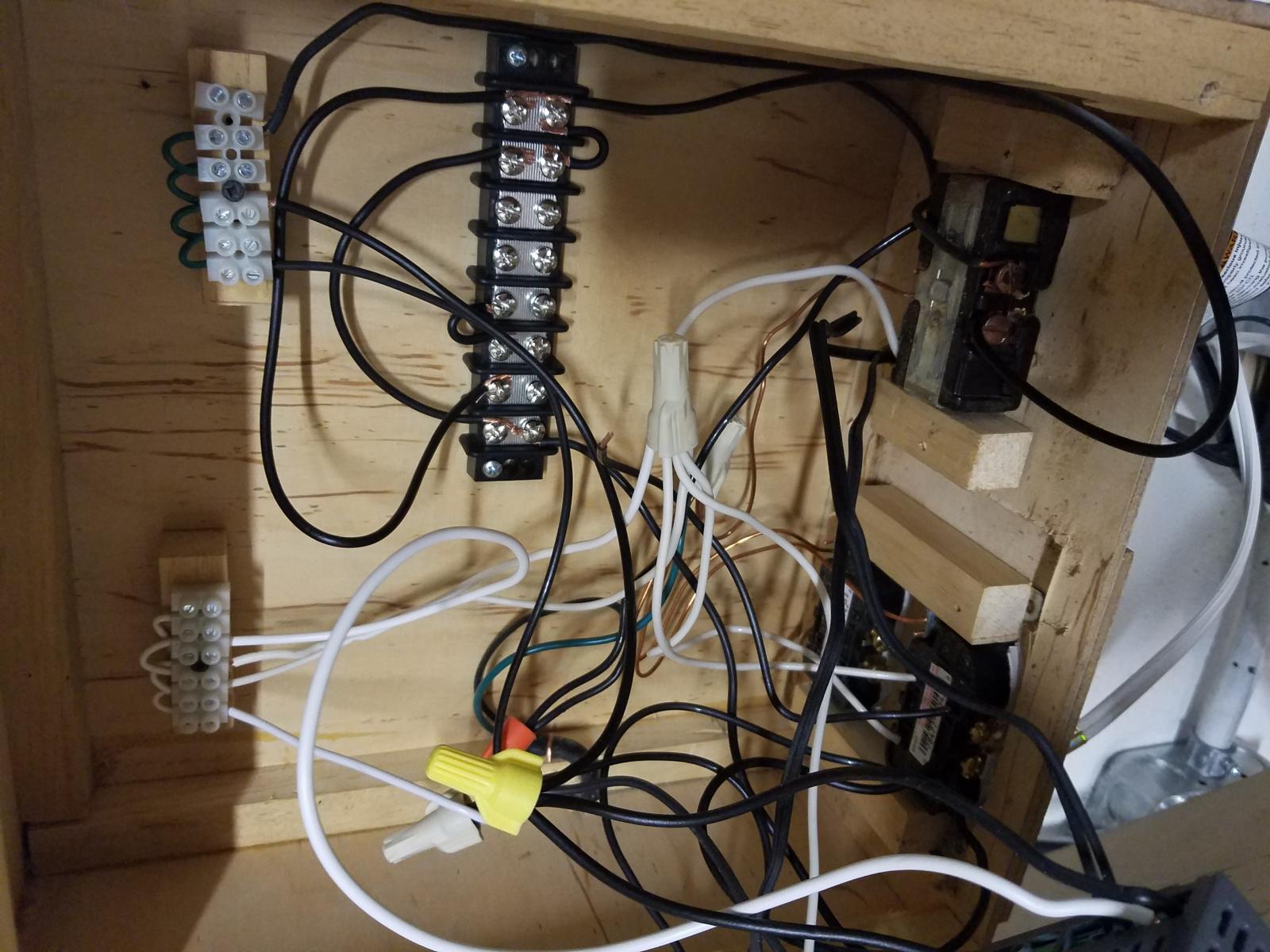

I have a question for the electrical engineer types out there. I've built a glycol chiller with a prototype control panel for fermentation. I currently have the manifold and control panel set up for for two fementers but it's expandable up to four, or as many as I want really. The manifold is supplied by one submersible pump that is energized when any solenoid is opened. It worked great with only one batch fermenting but when I tried to set it up for 2 I realized anytime a solenoid was opened and supplying power to the pump the other solenoid would also be energized because of the single pump. When power is supplied by one of the controllers to the solenoid/pump the power would just travel through to the other solenoid and open it. I think a relay between the solenoid and pump is the solution but I don't know what kind to use. Power goes from controller to solenoid outlet, solenoid outlet to pump outlet. Please excuse the sloppy wiring, like I said, it's just a prototype. The image with the wiring needs to be rotated to the right.