vinylrooster

Well-Known Member

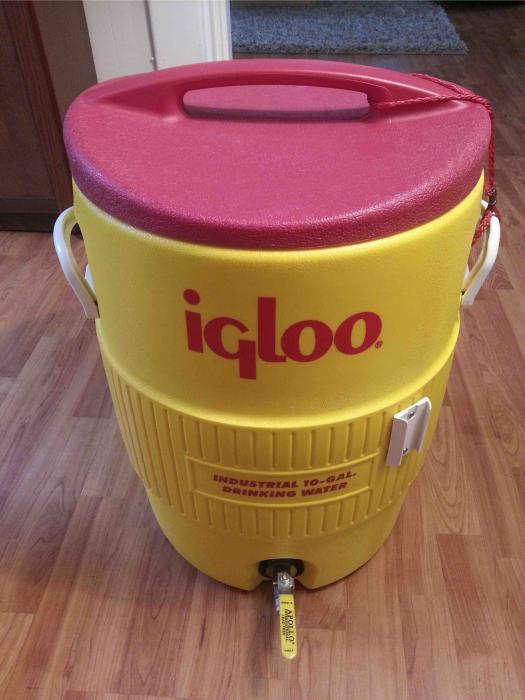

DIY Guide: MLT from Igloo 10-Gallon Commercial (yellow) Water Cooler

Let me start out this DIY guide by saying that the inspiration and instructions came almost verbatim from FlyGuy's original thread (https://www.homebrewtalk.com/f51/cheap-easy-10-gallon-rubbermaid-mlt-conversion-23008/). FlyGuy saved me multiple hours of making repeated trips to Home Depot in order to get all of the pieces for the build and I thank him immensely!

I had to change two or three minor things from his build in order to get a good tight seal to ensure no leaks on my Igloo 10 Gallon Industrial Water Cooler.

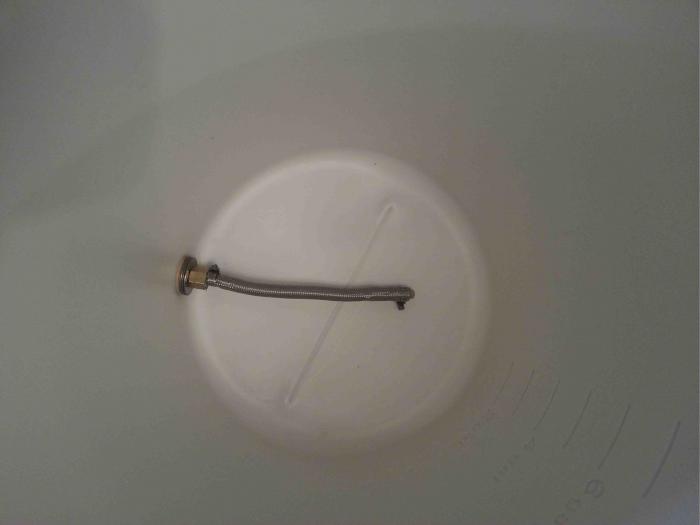

I'll start out with pictures of the final product and of the final inside view. I have also included a pdf document in case you would like to print the instructions out. It won't let me upload the pdf that contains all of the pictures for easy printing, but just PM me your email address if you would like them and I will gladly supply them for you.

Here was my parts list (again, thanks to FlyGuy for these product Cat #'s):

Here are the parts you will need for the conversion (see images 2 and 3):

Parts List:

- Igloo 10-Gallon Commercial (yellow one) Water Cooler

- Two stainless steel ¼ hose clamps

- One brass square head plug (Watts A-737)

- One ½ x 12 braided stainless steel supply hose

- One 3/8 female barb adapter (Watts A-298)

- Three 5/8 stainless steel fender washer

- One 3/8 MIP x 1-1/2 brass nipple (Watts A-786)

- One roll Teflon tape

- One 5/8 O-ring

- One neoprene 5/8" fender-type washer

- Five non-stainless steel 5/8 fender washers

- One 3/8 threaded ball valve (threaded on BOTH sides)

- One 3/8 male barb adapter (Watts A-294)

All of the above products were purchased at Home Depot, with the exception of the "Three 5/8" stainless steel fender washers" and "One neoprene 5/8" fender-type washer", which were both purchased at Ace Hardware.

View attachment DIY Mash Tun Guide.pdf