triskelion

Well-Known Member

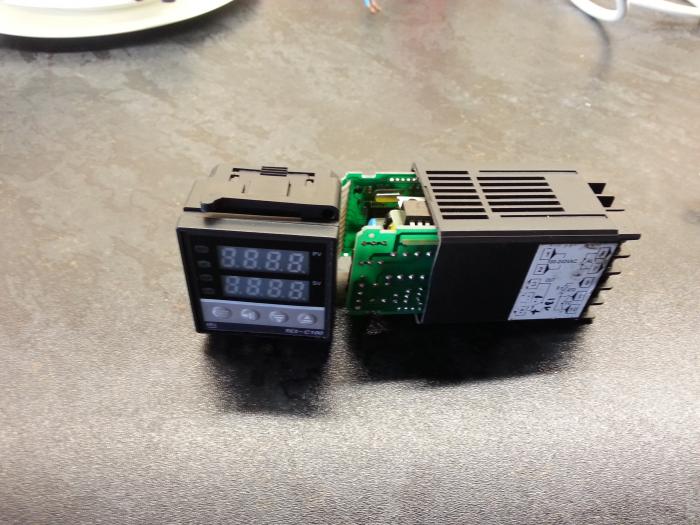

Got a keg and made a hole in it. this is the jig i made to guide the grinder. I decided not to use the top of the keg for a drain because I might be using a burco element, which would fit nicely in the flat part at the bottom of the keg. also, here's my orange hefeweizen which i am now drinking in toast to a perfectly cut circle

Still haven't decided on an element yet and am open to suggestion, btw camcos are going to be fairly expensive on this side of the pond after import tax.

Still haven't decided on an element yet and am open to suggestion, btw camcos are going to be fairly expensive on this side of the pond after import tax.