brad2157

Well-Known Member

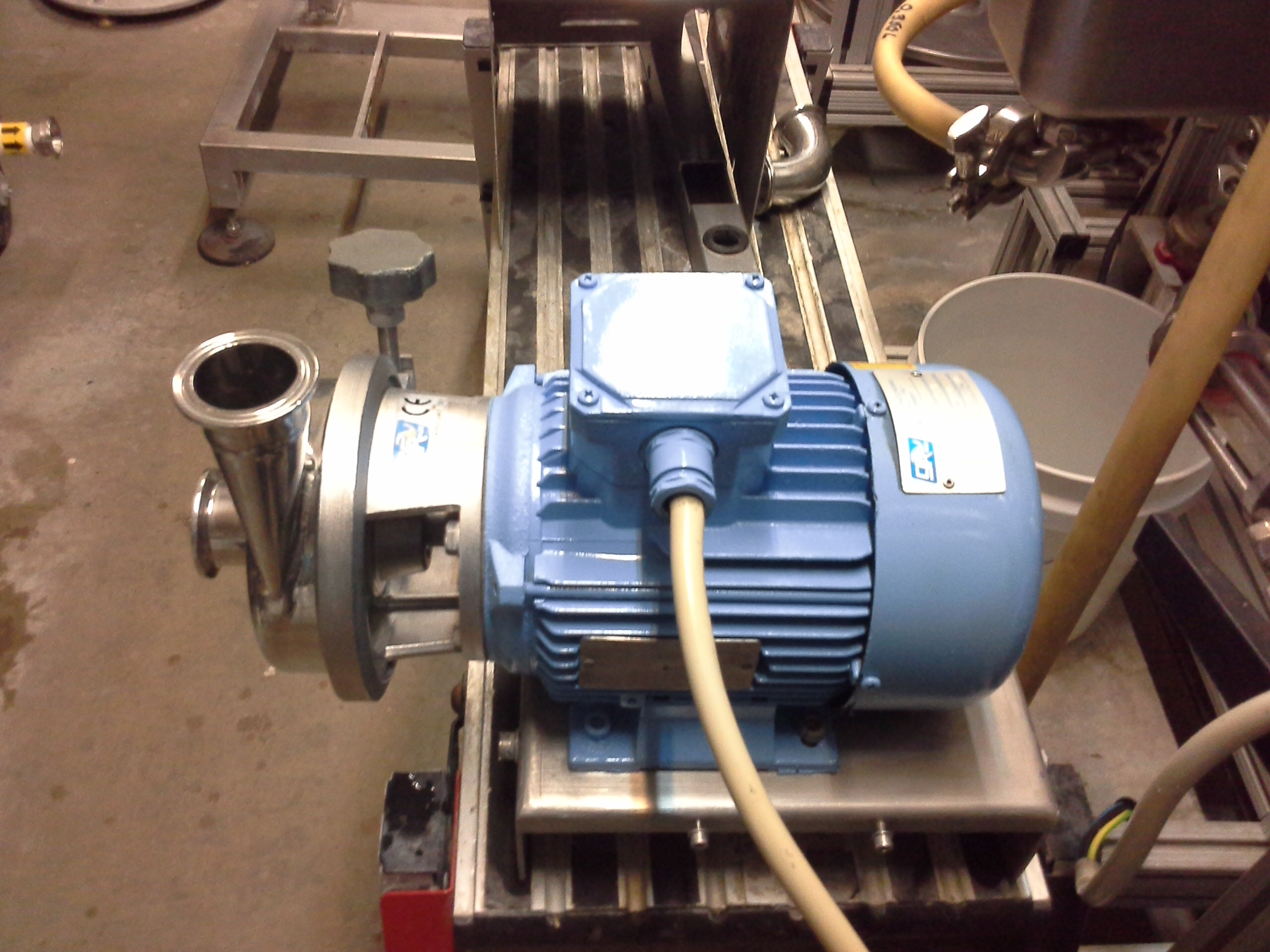

I am starting a motorized grain mill build. I picked up an electric motor, mm2 grain mill, and lovejoy couplers on eBay as a package deal a little while back. I’m always just as much concerned about appearance as well as functionality. I was wondering if I can paint the aluminum electric motor? Has anyone done this before? I know the motor is all aluminum and has heat sinks around the casing itself, but I’m not sure this will be running long enough at any given time (for home-brewing quantities) that it would ever get hot enough. I haven’t been able to find much online, other than I would need self-etching primer to get paint to adhere to the aluminum properly.

Thanks ahead of time for any help regarding this.

Thanks ahead of time for any help regarding this.