I removed the lid liner and luckily there was a space already hollowed out and it could fit the STC-1000. The hollow may have been intended for an option I did not have, like a light.

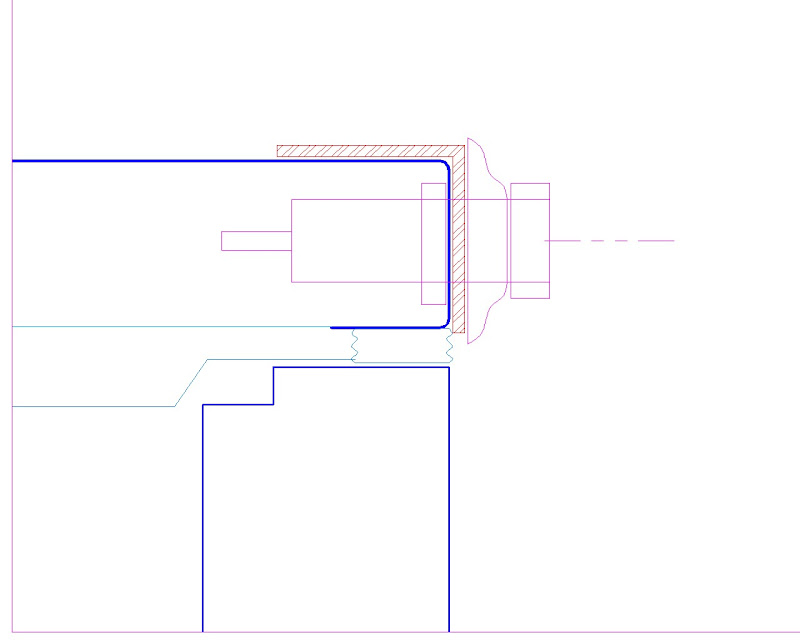

Below: I removed the lid and the lid liner. I had to cut off an inch of the plastic lift handle. That exposed a small sheet metal hole, which I enlarged with a sheetmetal nibbler to exactly fit the STC-1000.

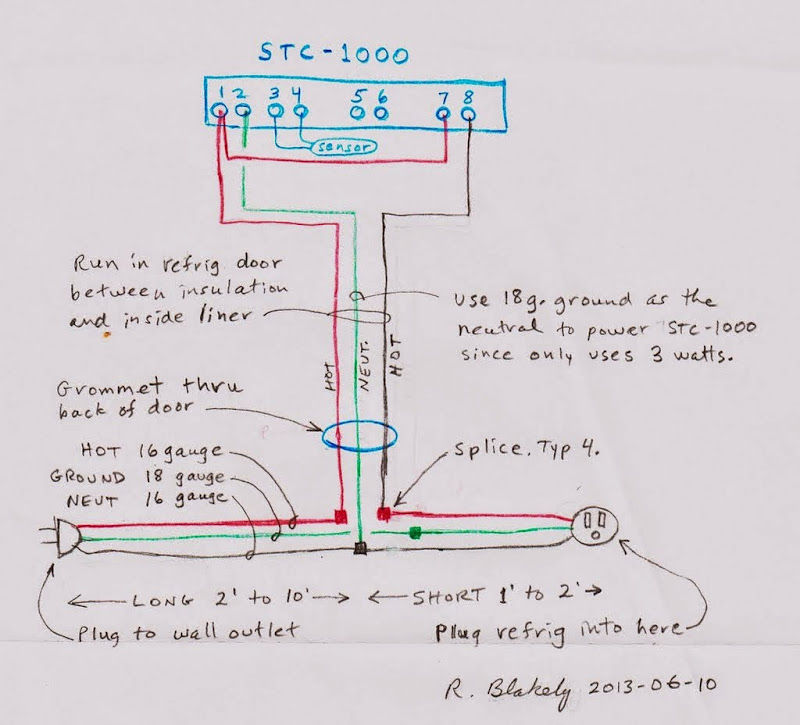

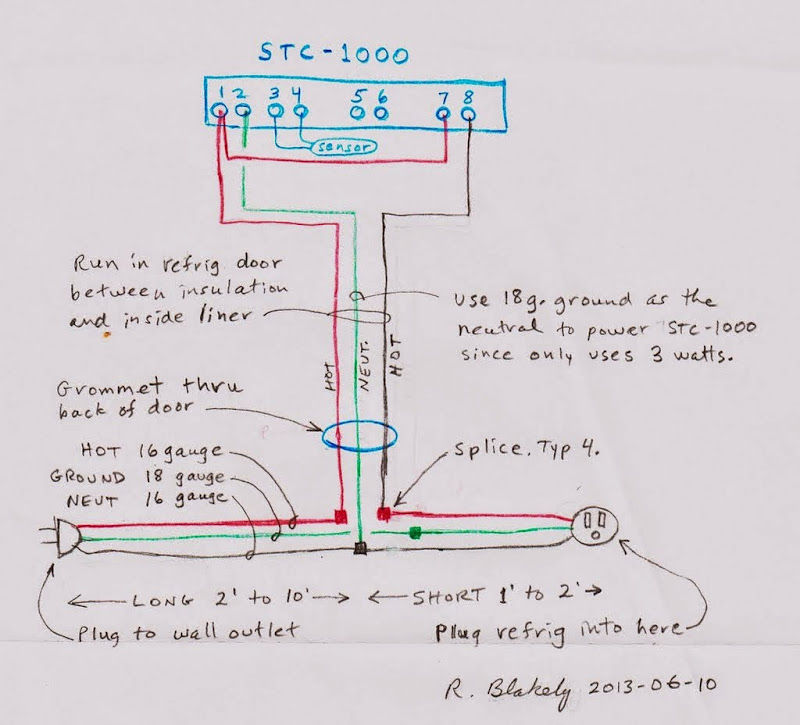

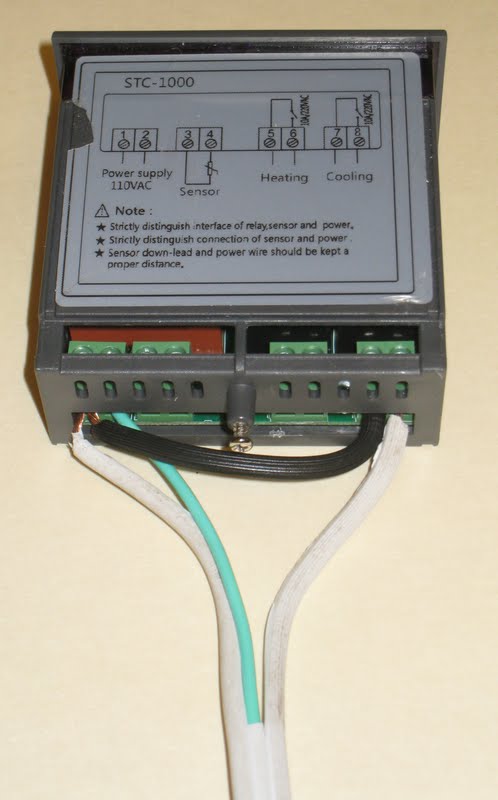

Below: I was able to use a 15' extension cord. The hot and neutral conductors are 16 gauge, the ground is 18 or 20 gauge. My keezer compressor only draws 150 watts (1.2 amps) so 16 gauge is plenty. I cut it into 3 pieces as shown on wiring diagram further down. 1) a short piece for the female part that the freezer plugs into, 2) a long piece for the male plug, and 3) a 5' long piece that connects to the STC-1000.

For the piece that went to the STC-1000 I changed the use of the green ground to be power for the STC-1000 which is only 3 watts, so a 20 gauge is plenty.

Below: The cavities were factory stuffed with fiberglass batting. I put that back in but it is not in photo. The cavities also had about 1/4" foam on the thin side. So the STC-100 is insulated all around before I clipped the liner back on the lid.

The cable did not need to be grooved or sunken into the foam. It just layed over the foam like the photo, and after I covered it with the liner, you could not tell it was there.

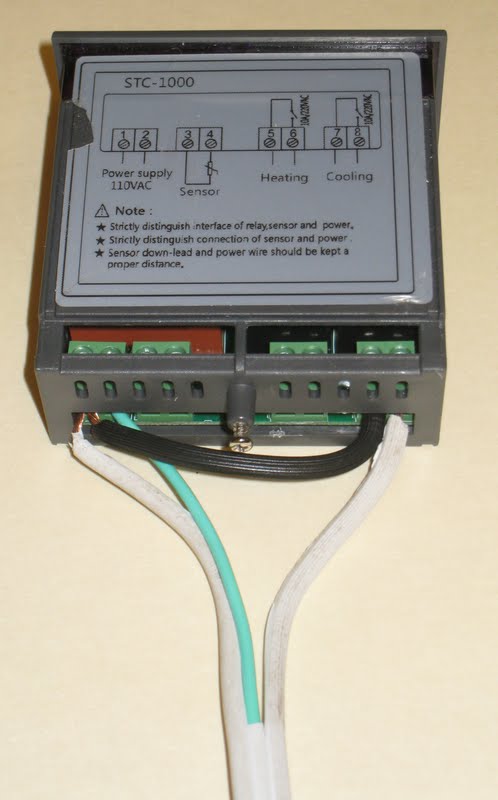

Below are the 4 splices shown on the wiring diagram. They were soldered and covered with shrink tube. No bulky boxes needed. I could have put some big shrink tube to bundle the splices.

Below: The temperture sensor pokes thru the lid liner near the back (the black wire). I can put it anywhere but I like it touching the top of keg.

This setup is only using about 0.4 kilowatt per day as measured by the "kill-a-watt" meter. http://www.p3international.com/products/p4400.html

I am a freak for using less energy, so I may have done things you would not do. Not having a wood collar for tap faucets, and no penetrations for a tower, keeps the heat out better. Wood conducts heat 5 times faster than polystyrene foam. The entire beer line stays cold since it is stored inside. I have been running it for about 10 days now and I am very happy with it.

Below: I removed the lid and the lid liner. I had to cut off an inch of the plastic lift handle. That exposed a small sheet metal hole, which I enlarged with a sheetmetal nibbler to exactly fit the STC-1000.

Below: I was able to use a 15' extension cord. The hot and neutral conductors are 16 gauge, the ground is 18 or 20 gauge. My keezer compressor only draws 150 watts (1.2 amps) so 16 gauge is plenty. I cut it into 3 pieces as shown on wiring diagram further down. 1) a short piece for the female part that the freezer plugs into, 2) a long piece for the male plug, and 3) a 5' long piece that connects to the STC-1000.

For the piece that went to the STC-1000 I changed the use of the green ground to be power for the STC-1000 which is only 3 watts, so a 20 gauge is plenty.

Below: The cavities were factory stuffed with fiberglass batting. I put that back in but it is not in photo. The cavities also had about 1/4" foam on the thin side. So the STC-100 is insulated all around before I clipped the liner back on the lid.

The cable did not need to be grooved or sunken into the foam. It just layed over the foam like the photo, and after I covered it with the liner, you could not tell it was there.

Below are the 4 splices shown on the wiring diagram. They were soldered and covered with shrink tube. No bulky boxes needed. I could have put some big shrink tube to bundle the splices.

Below: The temperture sensor pokes thru the lid liner near the back (the black wire). I can put it anywhere but I like it touching the top of keg.

This setup is only using about 0.4 kilowatt per day as measured by the "kill-a-watt" meter. http://www.p3international.com/products/p4400.html

I am a freak for using less energy, so I may have done things you would not do. Not having a wood collar for tap faucets, and no penetrations for a tower, keeps the heat out better. Wood conducts heat 5 times faster than polystyrene foam. The entire beer line stays cold since it is stored inside. I have been running it for about 10 days now and I am very happy with it.