BrewingCanuck

Member

- Joined

- Oct 22, 2018

- Messages

- 11

- Reaction score

- 5

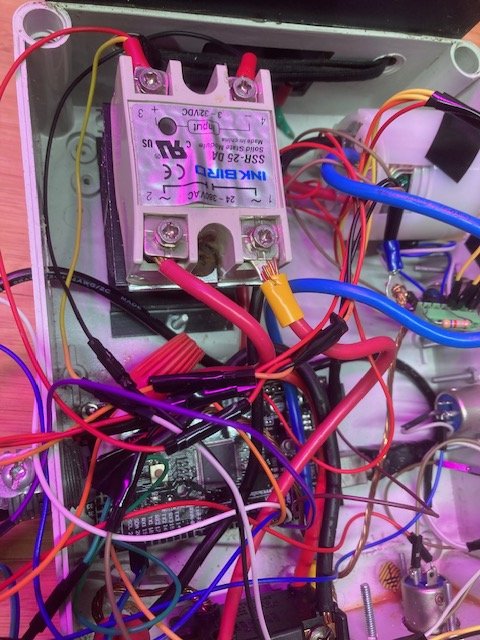

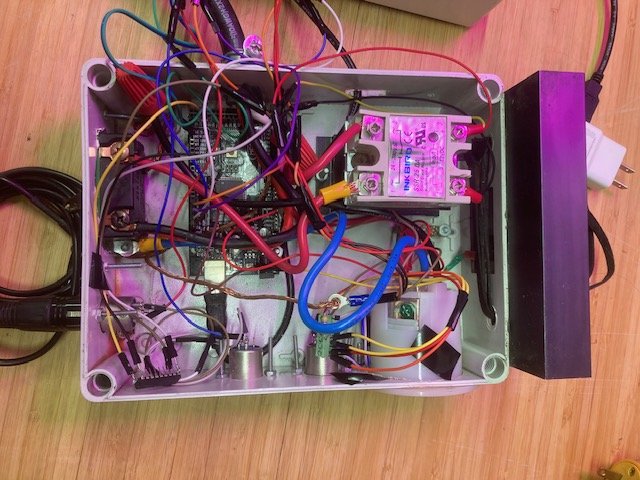

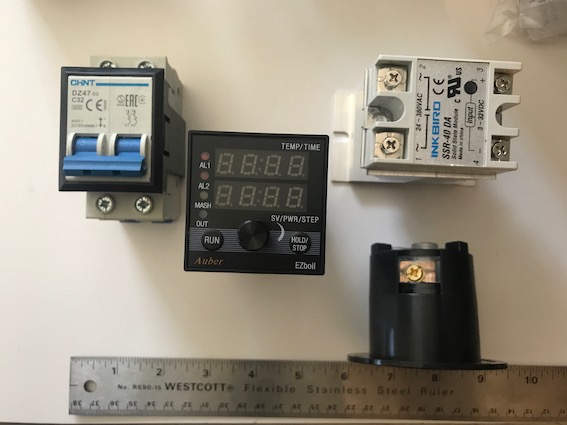

I recently bought a used brew pot and a controller was included, the PO said it was based on "https://github.com/wizbrewery/wiz-O...1Te5s2Xkt9k0o8tbUBLpOS7sshLdFIkirTj9ay2nOl1I8" what i have salvaged from this mess

is

SainSmart Mega 2560 https://www.sainsmart.com/products/mega ... compatible

LCD 2004A Module https://vegaprocessors.in/blog/lcd-2004 ... hejas-soc/

4 relay module https://www.arduinolearning.com/code/5- ... e_vignette

so what can I make? Wiring diagrams would be appreciated.

System is 240v

Thank you in advance.

is

SainSmart Mega 2560 https://www.sainsmart.com/products/mega ... compatible

LCD 2004A Module https://vegaprocessors.in/blog/lcd-2004 ... hejas-soc/

4 relay module https://www.arduinolearning.com/code/5- ... e_vignette

so what can I make? Wiring diagrams would be appreciated.

System is 240v

Thank you in advance.