AtticBrewing

Member

- Joined

- Feb 24, 2014

- Messages

- 11

- Reaction score

- 6

I'm new to HBT, but I've been lurking for a few years now. My keg washer build was inspired by many HBT users so I naturally cannot take full credit for it. So thanks to this awesome community!

I figured I'd post a quick album to document my build in case anyone was interested... Forgive the ****ty washed out cell phone pics!

It all starts with this 1" PVC flow-through spa manifold with (4) x 3/8" hose barb outlets. I installed a 3/8" ball valve on one barb for recirculating/dissolving cleaning chemicals

The heart of the system is the most powerful <$100 submersible oil-free mag drive pump I could find. It is a ~1600 GPH 245w (1/3hp!) unit that set me back $80, but this thing is a beast - http://www.amazon.com/dp/B0012V5VNW/?tag=skimlinks_replacement-20

First test fit in the 6.5gal bucket - you can also see the three holes for the panel-mount shutoff quick disconnects I will be using. I used a threaded ball valve on top so I can quickly install/uninstall various nozzles/attachments, as you will see below!

This is the first shot of the (mostly) completed assembly - showing the pump, panel-mount QD's, and keg/carboy washing nozzle. I used Colder QD's purchased from http://www.freshwatersystems.com/c-974-plc-series-acetal-couplings.aspx

This is the first test run - I had no support for the better bottle so I had to hold it!

Washing my first keg - I, like everyone else, made some liquid/gas jumpers to clean the dip tubes

I spent forever trying to find a large, shallow funnel I could use to catch fluid from a fermentation bucket or kettle - I had no luck... Until I stumbled upon this - http://www.amazon.com/dp/B000Z555P0/?tag=skimlinks_replacement-20 - it is actually the lid to a drum funnel. But 18.5" OD, shallow, and $12. Sold!

10 gallon, 15" OD Kettle - looking uncharacteristically shiny

The next challenge was connecting Ball Lock posts to the QD's. I unfortunately had to use a stack-up of 3 different adapters - Ball Lock Post --> Ball Lock x 1/4" FFL adapter --> 1/4" MFL x 1/4" FNPT --> 1/4" MNPT x QD. These ball lock posts cost some bucks, but cleaning three lines at a time makes it all worth it!

First run in beer line cleaning mode! Works like a charm!

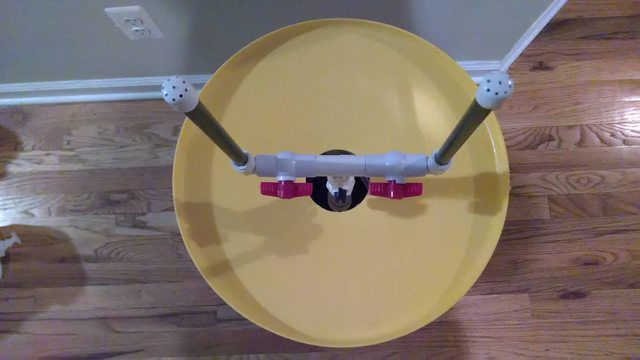

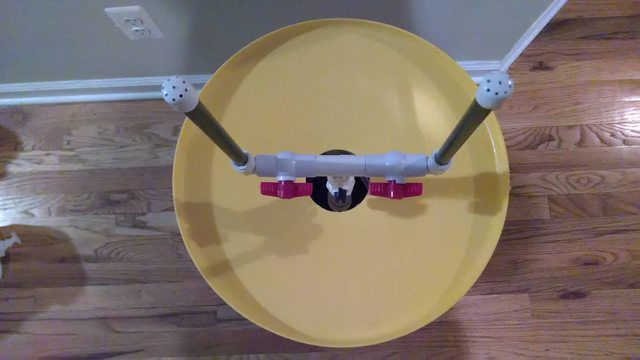

Since I had already gone through all this effort, I figured I might as well build a growler cleaning attachment. This snowballed into a dual growler cleaning attachment and here we have it. 3/8" PVC pipe is nearly impossible to find - I had to order a 5 ft. length from McMaster

Top view of growler cleaning setup. I use short 1.5" or 2.5" (depending on the growler) PVC collars to hold up the growlers and let them drain

The whole kit and caboodle laid out for your viewing pleasure

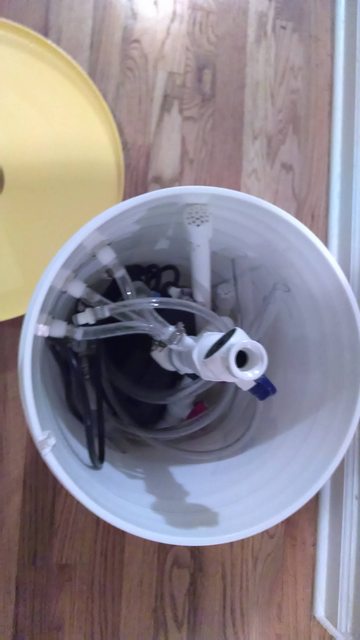

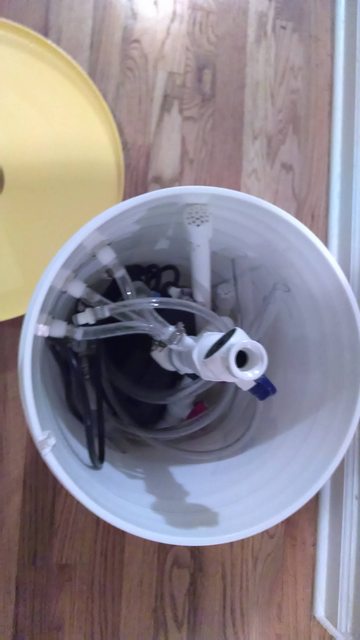

And everything fits in the bucket for storage (except for the big ass yellow drain pan)

And there you have it! I hope this post inspires some people to build their own contraptions or incorporate some of my ideas into their existing ones.

I'd also love to hear suggestions as to how this could be improved. I'm always tinkering.....

I figured I'd post a quick album to document my build in case anyone was interested... Forgive the ****ty washed out cell phone pics!

It all starts with this 1" PVC flow-through spa manifold with (4) x 3/8" hose barb outlets. I installed a 3/8" ball valve on one barb for recirculating/dissolving cleaning chemicals

The heart of the system is the most powerful <$100 submersible oil-free mag drive pump I could find. It is a ~1600 GPH 245w (1/3hp!) unit that set me back $80, but this thing is a beast - http://www.amazon.com/dp/B0012V5VNW/?tag=skimlinks_replacement-20

First test fit in the 6.5gal bucket - you can also see the three holes for the panel-mount shutoff quick disconnects I will be using. I used a threaded ball valve on top so I can quickly install/uninstall various nozzles/attachments, as you will see below!

This is the first shot of the (mostly) completed assembly - showing the pump, panel-mount QD's, and keg/carboy washing nozzle. I used Colder QD's purchased from http://www.freshwatersystems.com/c-974-plc-series-acetal-couplings.aspx

This is the first test run - I had no support for the better bottle so I had to hold it!

Washing my first keg - I, like everyone else, made some liquid/gas jumpers to clean the dip tubes

I spent forever trying to find a large, shallow funnel I could use to catch fluid from a fermentation bucket or kettle - I had no luck... Until I stumbled upon this - http://www.amazon.com/dp/B000Z555P0/?tag=skimlinks_replacement-20 - it is actually the lid to a drum funnel. But 18.5" OD, shallow, and $12. Sold!

10 gallon, 15" OD Kettle - looking uncharacteristically shiny

The next challenge was connecting Ball Lock posts to the QD's. I unfortunately had to use a stack-up of 3 different adapters - Ball Lock Post --> Ball Lock x 1/4" FFL adapter --> 1/4" MFL x 1/4" FNPT --> 1/4" MNPT x QD. These ball lock posts cost some bucks, but cleaning three lines at a time makes it all worth it!

First run in beer line cleaning mode! Works like a charm!

Since I had already gone through all this effort, I figured I might as well build a growler cleaning attachment. This snowballed into a dual growler cleaning attachment and here we have it. 3/8" PVC pipe is nearly impossible to find - I had to order a 5 ft. length from McMaster

Top view of growler cleaning setup. I use short 1.5" or 2.5" (depending on the growler) PVC collars to hold up the growlers and let them drain

The whole kit and caboodle laid out for your viewing pleasure

And everything fits in the bucket for storage (except for the big ass yellow drain pan)

And there you have it! I hope this post inspires some people to build their own contraptions or incorporate some of my ideas into their existing ones.

I'd also love to hear suggestions as to how this could be improved. I'm always tinkering.....

Last edited by a moderator: