So without giving it much thought last year, I bought two of these 11 gallon Bayou Classic Kettles:

http://www.amazon.com/dp/B000VXHKMC/?tag=skimlinks_replacement-20

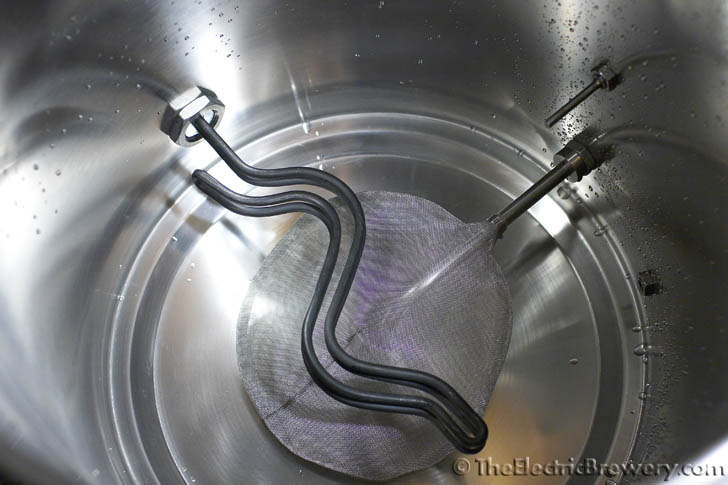

My plan was to install the following heating element in the two kettles to serve as my HLT and BK:

http://www.amazon.com/dp/B000BPG4LI/?tag=skimlinks_replacement-20

The issue is that the ID of the kettles are ONLY 13.5"! I'm struggling to find any other ultra low watt density elements that are less than 14" long (and still affordable).

I was thinking if I could find a 1" NPT coupler to essentially "extend" the threaded portion so I could "shorten" the heating element length in the kettle, I may be able to solve my problem. Do you guys have any other thoughts that could help me out?

Thanks

http://www.amazon.com/dp/B000VXHKMC/?tag=skimlinks_replacement-20

My plan was to install the following heating element in the two kettles to serve as my HLT and BK:

http://www.amazon.com/dp/B000BPG4LI/?tag=skimlinks_replacement-20

The issue is that the ID of the kettles are ONLY 13.5"! I'm struggling to find any other ultra low watt density elements that are less than 14" long (and still affordable).

I was thinking if I could find a 1" NPT coupler to essentially "extend" the threaded portion so I could "shorten" the heating element length in the kettle, I may be able to solve my problem. Do you guys have any other thoughts that could help me out?

Thanks

Last edited by a moderator: