You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Ugly Junk- Corona Mill Station...

- Thread starter Revvy

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

BeerMeThatBeer

Well-Known Member

Note: after launching my own thread - i was wisely advised to re-post this here. probably the natural home for this creation/monstrosity.

i'm way more into functional junk, than pretty junk. i've just started a mini-fridge kegerator build; will keep you posted. promises to be just as fugly

-beermethatbeer

Orig Post:

Hey All - figured I'd post this up for those of us who are not in the least DIY-Savvy, but still like to give it a shot!

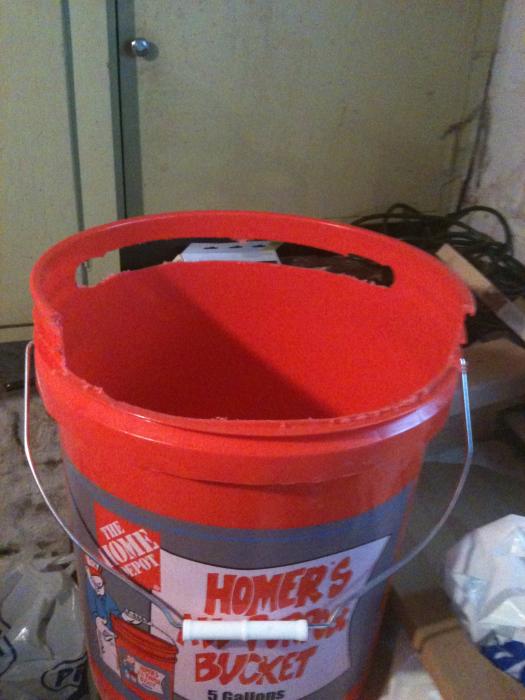

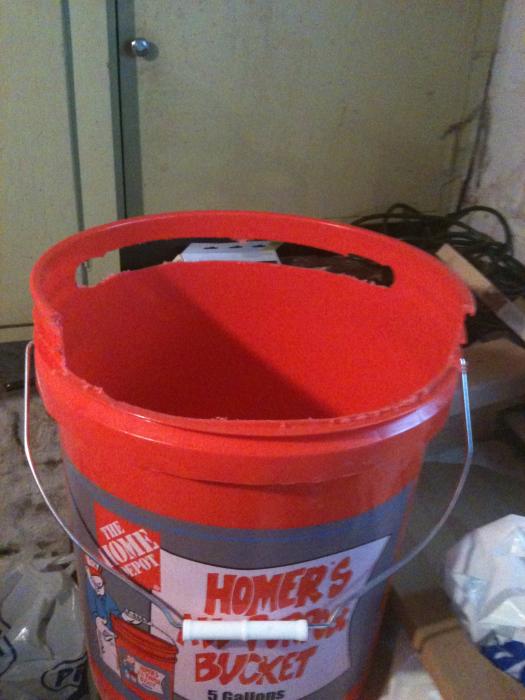

Been wanting to mill my own for awhile, picked up a $25 corona mill and a homer bucket and here you go. (pics at bottom)

Step1: massacre a homer bucket. notch the top on one side so a board sits flat, and make an opening in the other.

Step2: cut a hole in a board. attach Corona mill; grocery store bag attached to bottom to direct grains into homer bucket.

Step3: massacre a vinegar bottle for hopper. attach with post office tape.

Step4: is a little tilty, so counter weight on left side with something; random basement wood will do.

What do you think? my efficiency has been unpredictable (from the 60's to the 80's) - - so looking forward to crushing my own to pin down that variable.

Have an Amarillo Pale Ale planned for about 2 weeks; so hopefully I can report back that this mess didn't fall apart after 10lbs. (tests are looking positive).

_beermethatbeer

i'm way more into functional junk, than pretty junk. i've just started a mini-fridge kegerator build; will keep you posted. promises to be just as fugly

-beermethatbeer

Orig Post:

Hey All - figured I'd post this up for those of us who are not in the least DIY-Savvy, but still like to give it a shot!

Been wanting to mill my own for awhile, picked up a $25 corona mill and a homer bucket and here you go. (pics at bottom)

Step1: massacre a homer bucket. notch the top on one side so a board sits flat, and make an opening in the other.

Step2: cut a hole in a board. attach Corona mill; grocery store bag attached to bottom to direct grains into homer bucket.

Step3: massacre a vinegar bottle for hopper. attach with post office tape.

Step4: is a little tilty, so counter weight on left side with something; random basement wood will do.

What do you think? my efficiency has been unpredictable (from the 60's to the 80's) - - so looking forward to crushing my own to pin down that variable.

Have an Amarillo Pale Ale planned for about 2 weeks; so hopefully I can report back that this mess didn't fall apart after 10lbs. (tests are looking positive).

_beermethatbeer

Shakybones

Well-Known Member

I finally got some pics of my ugly junk and my grind, so I thought I'd contribute them to one of my favorite HBT threads. Many thanks to Revvy, wilserbrewer, and all the other awesome contributors!

First, the junk:

Then the grind:

The bucketful:

Next comes the drill attachment (boy are my arms tired), the bucket lid, and the water bottle hopper!

Please do comment on the grind and any adjustments you'd recommend!

First, the junk:

Then the grind:

The bucketful:

Next comes the drill attachment (boy are my arms tired), the bucket lid, and the water bottle hopper!

Please do comment on the grind and any adjustments you'd recommend!

WesleyS

Well-Known Member

- Joined

- May 1, 2012

- Messages

- 13,496

- Reaction score

- 4,217

Shakybones said:I finally got some pics of my ugly junk and my grind, so I thought I'd contribute them to one of my favorite HBT threads. Many thanks to Revvy, wilserbrewer, and all the other awesome contributors!

First, the junk:

Then the grind:

The bucketful:

Next comes the drill attachment (boy are my arms tired), the bucket lid, and the water bottle hopper!

Please do comment on the grind and any adjustments you'd recommend!

Don't be afraid to crank that thing down some more. It looks like quite a few whole grains are getting through.

idrinkstuffnthings

Well-Known Member

- Joined

- Jan 23, 2013

- Messages

- 135

- Reaction score

- 5

Ya I read somewhere "crank down till your scared, then just a little more" it's good advise. Haven't stuck a sparge yet and my stuff gets pretty floury.

Shakybones

Well-Known Member

I'm lazy, so I went ahead and mashed it, batch sparged. Got 63% efficiency. I'll definitely crank it down next time. Thanks, guys!

MMJfan

Well-Known Member

Just curious where did you guys get that metal cover that goes over the grinding area? Mine didn't come with one.

Mine came with...

MotorcycleMatt

Well-Known Member

Mines plastic, came with it. It does an ok job keeping tue kernels from flying

spkguitar

New Brew Dude

Yeah, mine came without a cover as well, and that's what I did; cut up a milk jug to direct the grain. Angled it to accomodate for the adjustment in the front, and then clamp it down with the wing nuts on the back. Cut the bottom out of an old pretzel bucket to use as a hopper too. Fits perfectly. I can get 10# of grain in the hopper at a time.

WyomingBrewer

Well-Known Member

Bucket grinder built this morning.....awesome idea! Thanks Homebrewtalk!!!!! Pictures coming soon as they arrive from cyber space somewhere!

WyomingBrewer

Well-Known Member

Here it is!

JoeyChopps

Well-Known Member

I think it needs some duct tape or gorilla glue. That thing is too pretty. Good job.

rico567

Well-Known Member

Needs a little more "ugly," but I bet it performs! I use the same design- I duct-taped an old water bottle to the funnel so I could load the whole grain bill at once (it will hold >20 lbs), and for a lot of my beers I cut a hole in the bottom of the bucket with the mill in it and set it into another bucket so I can mill the whole thing.

WyomingBrewer

Well-Known Member

So.....I need to ugly it up? Let me think about it...lol. Thanks folks.

WyomingBrewer

Well-Known Member

It is the only mill i have in my shop....got to grind 1 recipe so far today! This thing sings with a 4.2 amp motor drill on it though the drill heats up. But I bet I wont wear out the drill between uses....I hope I do, means business is great.....but prolly wont.!

chefcurt

Well-Known Member

I got a victoria mill for christmas and I am just now starting to tinker with it. I have it all put together but the crank is VERY difficult to turn. It is set pretty loose so that can't be the problem. The plates are not touching. I'm thinking it could be a slightly off casting and something is rubbing causing it to stick. I feel like if I can grind it down slightly where the rubbing is happening then that could solve my problem. Any reason why I shouldn't do this?

Try loosening and repositioning the two wing nuts at the front of the mill... My guess is the burr shaft is binding and it is clamped out of alignment

chefcurt

Well-Known Member

wilserbrewer said:Try loosening and repositioning the two wing nuts at the front of the mill... My guess is the burr shaft is binding and it is clamped out of alignment

Thanks! Ill give it a shot.

wickman6

Well-Known Member

Here's my junk, and it grinds out grain quite nicely as you can see. I started conditioning and its awesome! I highly recommend it if you don't already.

The drill died however, so now I rigged up an old Milwaukee buffer to run the mill. It's a beast.

The drill died however, so now I rigged up an old Milwaukee buffer to run the mill. It's a beast.

Here's my junk, and it grinds out grain quite nicely as you can see. I started conditioning and its awesome! I highly recommend it if you don't already.

The drill died however, so now I rigged up an old Milwaukee buffer to run the mill. It's a beast.

That is one of the ugliest POS I've seen in a long time on here....

YOU WIN!!!!! For the first half of 2013 I award you;

Indian_villager

Well-Known Member

I'm not sure that beats the one with the KFC bucket. For craps sake I'm confident that the bucket still had grease stains on it.

Did some updating of my ugly junk. Re-purposed a cabinet, screwed some pallets to the top to secure the hopper from tipping over, made a cut-out for the drill (bungee'd to the bucket), and then cut the top of a bucket off so I could slide it up on the mill bucket, put the "catcher" bucket underneath, then nest the cut-off inside the catcher. Does that make sense? You can probably tell in the pic.

Real fancy.

Real fancy.

Lookin good!

Just a heads up to all "ugly Junkers", I recently had my drill temporarily rigged to the mill, well apparently not very well!

I guess the drill had some wobble and eventually snapped the bolt flush with the handle shaft of the mill.

I thought my corona might be a goner, but after ample cussing, drilling, and chasing the threads with a tap, I'm back in business w/ a new cut off bolt.

In hindsight, it might be cleaner to drive the mill w/ a hex bolt and socket, rather than chucking on to the bolt shaft.

My pain hopefully your gain all...cheers!

Just a heads up to all "ugly Junkers", I recently had my drill temporarily rigged to the mill, well apparently not very well!

I guess the drill had some wobble and eventually snapped the bolt flush with the handle shaft of the mill.

I thought my corona might be a goner, but after ample cussing, drilling, and chasing the threads with a tap, I'm back in business w/ a new cut off bolt.

In hindsight, it might be cleaner to drive the mill w/ a hex bolt and socket, rather than chucking on to the bolt shaft.

My pain hopefully your gain all...cheers!

rico567

Well-Known Member

Lookin good!

Just a heads up to all "ugly Junkers", I recently had my drill temporarily rigged to the mill, well apparently not very well!

I guess the drill had some wobble and eventually snapped the bolt flush with the handle shaft of the mill.

I thought my corona might be a goner, but after ample cussing, drilling, and chasing the threads with a tap, I'm back in business w/ a new cut off bolt.

In hindsight, it might be cleaner to drive the mill w/ a hex bolt and socket, rather than chucking on to the bolt shaft.

My pain hopefully your gain all...cheers!

I've been chugging along ever since I built my setup with the same 13mm x 2 inch 25-cent bolt I started out with. I had the socket and adapter already, so it seemed the logical way to go. No problems, and I think that the fact that the bolt head & socket are able to "wobble" a bit actually helps take some stress out of it, although it's just slapped together.

In hindsight, it might be cleaner to drive the mill w/ a hex bolt and socket, rather than chucking on to the bolt shaft.

That's what I do, hex bolt and socket.

Favorite part of my "new" setup is that I can walk away from the milling station. Before I had to keep my eye on the drill, hopper, etc. to make sure I didn't have 15lbs. of grain on the floor when I got back.

Fwiw, the broken bolt was self inflicted, about a year ago I grab Ed what was in reach to support the drill for hands free milling, I guess a bungee cord and a scrap of PVC pipe weren't enough haha, likely had large load and wobble equals broken bolt.

Starting to regret passing on the nice wooden kitchen cart I saw at a garage sale few weeks ago

Starting to regret passing on the nice wooden kitchen cart I saw at a garage sale few weeks ago

user 78027

Well-Known Member

- Joined

- Apr 15, 2011

- Messages

- 274

- Reaction score

- 13

I'm struggling with my efficiency, I brewed yesterday and the result was a dismal 46%. So, I am going back and looking at everything to figure out how to improve somehow. I have my grain milled at the LHBS and yesterday I milled it twice. I went back today and got two one lb samples, one milled once and the other milled twice. I have included the images here hoping someone will tell me if it needs to be better or if I need to look elsewhere.

In the first image the grain was ground once and in the second image twice.

Thanks for your help.

In the first image the grain was ground once and in the second image twice.

Thanks for your help.

I'm struggling with my efficiency, I brewed yesterday and the result was a dismal 46%. So, I am going back and looking at everything to figure out how to improve somehow. I have my grain milled at the LHBS and yesterday I milled it twice. I went back today and got two one lb samples, one milled once and the other milled twice. I have included the images here hoping someone will tell me if it needs to be better or if I need to look elsewhere.

In the first image the grain was ground once and in the second image twice.

Thanks for your help.

Those pics are so small and not expandable, so I can't really tell. Bottom line is that you don't want ANYTHING that looks like a whole grain. You want pieces of husks and chunks of endosperm, along with flour, yes, flour.

user 78027

Well-Known Member

- Joined

- Apr 15, 2011

- Messages

- 274

- Reaction score

- 13

Those pics are so small and not expandable, so I can't really tell. Bottom line is that you don't want ANYTHING that looks like a whole grain. You want pieces of husks and chunks of endosperm, along with flour, yes, flour.

I added larger images. I don't know how big I can upload here.

rico567

Well-Known Member

Hard to tell.....too far away. But my impression is that you need to crank your Corona down a turn or so, then try it. The rule, first espoused by "wilserbrewer, " is "crank it down 'til you're scared, then give it another half-turn."

Three words is all you need, "all grains crushed".

user 78027

Well-Known Member

- Joined

- Apr 15, 2011

- Messages

- 274

- Reaction score

- 13

So, your telling me I don't really have a choice but to buy one of those corona mills, urgh. Its not the money, if I didn't I would have to buy more grain so the money gets spent. I just don't need more variables in the equation while I figure this process out. By the same token, I am really tired of the result not getting much better as I keep making changes. I have the feeling this is more fundamental and things won't get that much better until I get this done.

So, your telling me I don't really have a choice but to buy one of those corona mills, urgh. Its not the money, if I didn't I would have to buy more grain so the money gets spent. I just don't need more variables in the equation while I figure this process out. By the same token, I am really tired of the result not getting much better as I keep making changes. I have the feeling this is more fundamental and things won't get that much better until I get this done.

That's a piss-poor crush by the LHBS. Some of the old guard believe you just barely want to crack the grains. I've lost 10% efficiency when I had even a fraction of my grains whole or nearly-whole. My runoff has been slow at times, but I am stuck on 80% efficiency no matter what else changes, as long as I crush my grains the way I always have. It's nice to know you'll hit your numbers.

n240sxguy

Well-Known Member

So which version of these mills do you guys use? I've seen a Corona, Victoria, and some generic that has "500" cast into the side that doesn't have a shield over the plates. The cheap "500" looks like a POS, but it's cheaper. I'm already questioning this type of mill. If I get one, I want it to be a good one; not a piece of junk that's gonna break.

Shakybones

Well-Known Member

I got mine from Discount Tommy (through Amazon - http://www.amazon.com/gp/product/B000U5NZ4I). It is a cheap piece of shizz ($27, free shipping), but it does the job very well. I didn't even need the adjustments (washers, etc.) that others did to get it to grind. I've now hooked a monster drill up to it and run it on full speed. Hasn't broken yet. I haven't heard many others that abuse their junk complain about breakage.

Do it!

Do it!

Last edited by a moderator:

rico567

Well-Known Member

I got mine from Discount Tommy (through Amazon - http://www.amazon.com/gp/product/B000U5NZ4I). It is a cheap piece of shizz ($27, free shipping), but it does the job very well. I didn't even need the adjustments (washers, etc.) that others did to get it to grind. I've now hooked a monster drill up to it and run it on full speed. Hasn't broken yet. I haven't heard many others that abuse their junk complain about breakage.

Do it!

This is what I did, three years ago when DT had them for $23. Yes, they are very cheap and crudely made. No, it has never broken, through milling dozens of batches of malt. And I hit my numbers when I mash with almost boring consistency, which means that the mill (mine is a "Victoria" with "500" on the side) is as capable of milling malt as any roller mill out there. Just crank it down until all grains are crushed.

Last edited by a moderator:

Similar threads

- Replies

- 15

- Views

- 2K