toadhall

Well-Known Member

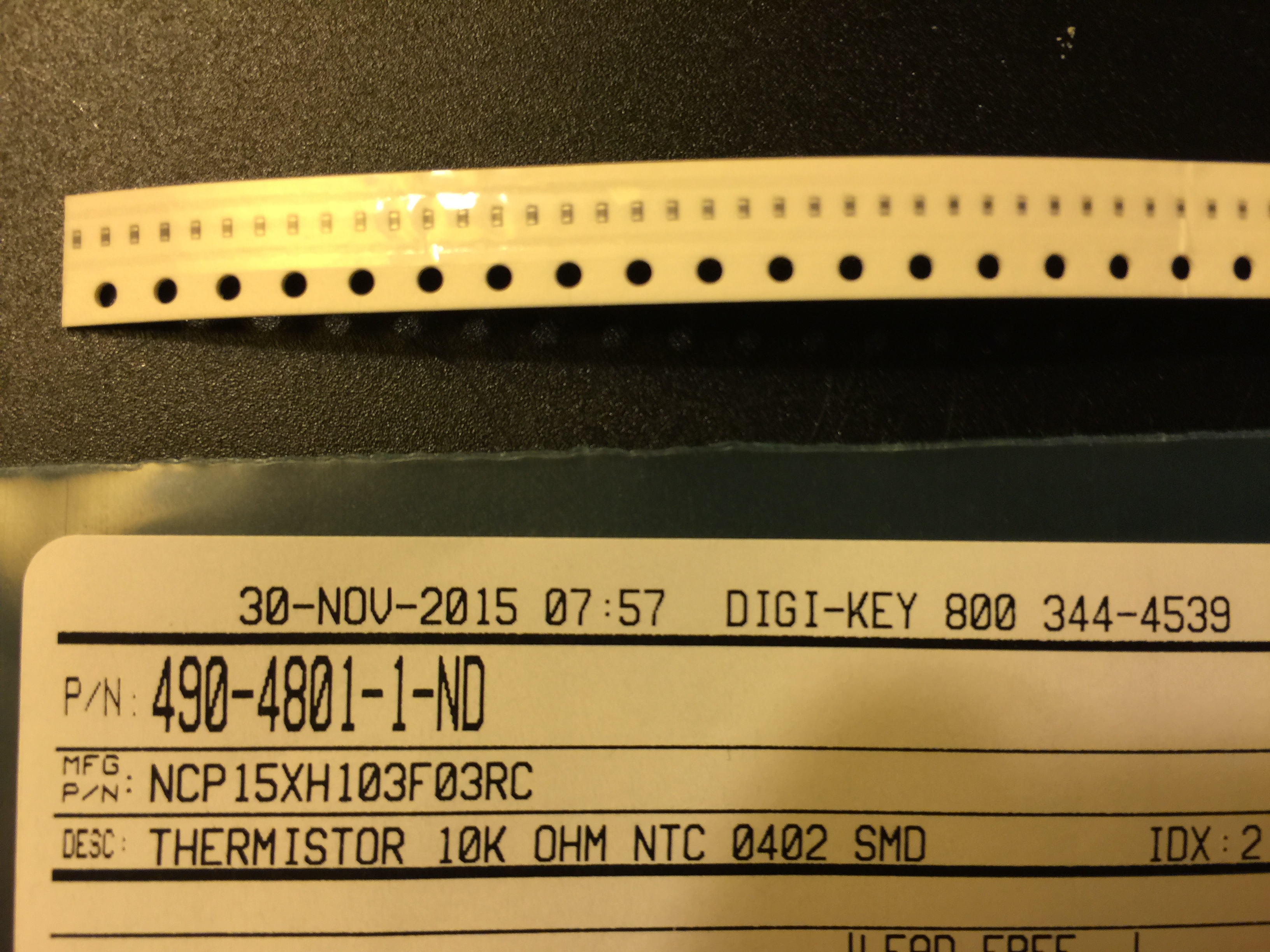

I found some old threads having to do with using the Coolbot and a window air conditioner for refrigeration of a coldroom. I got involved with some agriculture folks who were going to use a Coolbot to chill produce and when I looked into it and saw the simplicity of this concept I built a controller for them based on an Arduino (I used the Pro Mini 328P, but it could be done with any of the Arduino family). This is a very simple control concept; I worked out how to make inexpensive probes of very good quality and a "heater" using a simple 3W power resistor ($1.50), so I have a $15 mimic of Coolbot - without display or buttons - fits in a small mint tin - you just program it for a temperature you like (I set for 42F) and that's it - easy to reprogram as needed, and easy to add more features (settable temperature, display, etc) if you need that. It should control an AC in the same way as the Coolbot. I wanted a very stripped down controller for this prototype for simplicity and reliability, and have done the testing to show it is working as planned and the prototype is off to the growers for actual testing to start in June 2015; the control program may require some revision since I don't have an AC unit for testing and will have to see how it works in actual practice.

I am referring to this as the "Coldsnap". Nothing is for sale - this is info for DIY people. I'm just putting the info out there to save people some development time; it is a starting point that could be easily modified to include more features - the prototype assumes you want a cold room, like a fridge, and don't need a lot of temperature setting once your decision is made.

The info, code and images are on my website: http://people.umass.edu/~dac/projects/ColdSnap/ColdSnap.html

The page/info is under construction but I've got the essence of it up, including a schematic for the controller.

Hope this is useful to someone.

Cheers!

I am referring to this as the "Coldsnap". Nothing is for sale - this is info for DIY people. I'm just putting the info out there to save people some development time; it is a starting point that could be easily modified to include more features - the prototype assumes you want a cold room, like a fridge, and don't need a lot of temperature setting once your decision is made.

The info, code and images are on my website: http://people.umass.edu/~dac/projects/ColdSnap/ColdSnap.html

The page/info is under construction but I've got the essence of it up, including a schematic for the controller.

Hope this is useful to someone.

Cheers!