- Joined

- Mar 12, 2007

- Messages

- 6,841

- Reaction score

- 857

Looking forward to hearing your final results.

Yes. See my comments in my last post (3 posts above).Have you tasted it yet?

Yes. See my comments in my last post (3 posts above).

Kal

It has not completeley carbed and settled yet. In 2-4 weeks will be best.

Kal

gandelf said:Have you tasted it yet? The last three batches of APA/IPA I have done the same way, with the exception I BIAB. For me, the 170F 80 minute hop stand provides the best taste and level of hop flavor and aroma. Again for me, fermentation does strip a significant amount ~50 - 70 percent of the aroma and ~ 25 percent flavor. So, I torpedo (march pump/whole house filter) 3 to 6 ounces of leaf hops at 65 degrees for 2 days. Torpedoing also brightens up my hoppy ales significantly.

It works for me; I have been torpedoing for aprox. 9 months and ALL of my hoppy beers get it and a few non-hoppy beers also. By the way, very nice documentation and pics.

Would you mind elaborating a bit on your torpedo process? Do you recirculate your fermenting/fermented beer to/from the fermentation vessel through your whole house filter packed with leaf hops continuously for 2 days?

How long do you recirculate for?My torpedo process is on here somewhere? I basically keg the beer, use another empty keg to push sanitizer through, put the hops in a sack and then use the keg to purge with co2.

How long do you recirculate for?

Do you find it produces a different taste than just dry hopping longer?

The main reasons for using a torpedo as told by Steve Dresler (brewmaster at SN) is to more effectively and efficiently extract the volatile hop oils. Prior to this using giant hop bags resulted in poor saturation and therefore slower extraction of hop oils. Longer contact time was needed with more hops.

So from what I understand, it's just to speed up the process but I'm curious what you think. In a commercial brewery where they're always looking to clear tanks for the next batch.

Kal

Kal. Just saw this thread on IBU testing.

Would be the perfect beer to test this service...

Yes it would! Very interesting. Thanks for posting.Kal. Just saw this thread on IBU testing.

Would be the perfect beer to test this service.

+1 on this. Take advantage of the service now before the guy realizes $5 per IBU test just isn't worth the bother!!!

I mashed mine at 150F, used US-05 in one fermenter and WY1056 in another as part of a separate test.Have multiple people brew either the exact same recipe or a recipe with restrictions so that participants show off their skills and to evaluate the differences between beers with minimal variables. This one is a little more open. Enjoy!

Style: American Pale Ale

Rules:

1. Sign Up

2. Brew the recipe. Only substitutes are those noted.

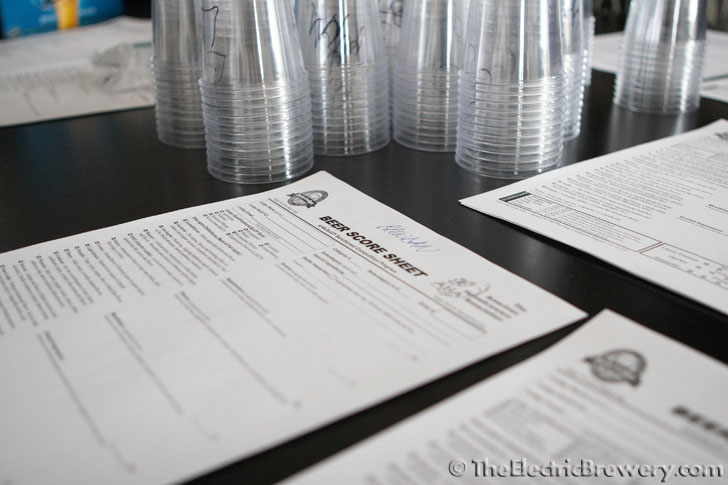

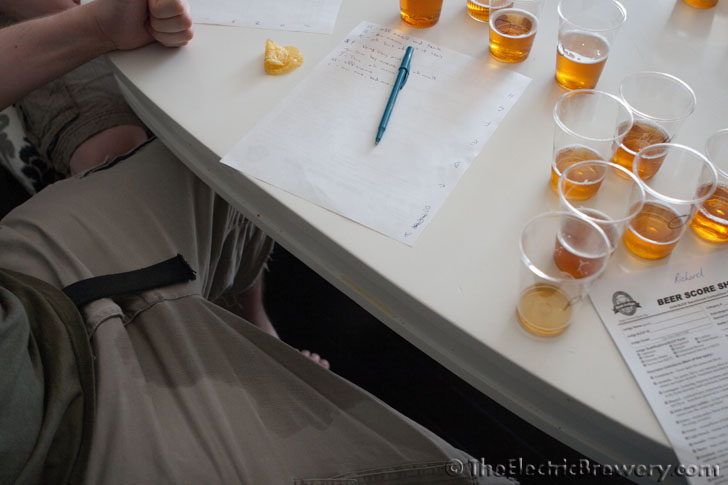

3. Present your sample at the Throwdown on May 4th.

4. Bring your recipe/brewsheet to the Throwdown for comparative purposes.

5. One official entry per person.

Targeted OG (adjust grain bill to hit this OG): 1.052

Grain: (Mash Temp: OPEN)

90% 2-row

5% Crystal 60L or Caramunich equivalent

5% Carafoam/Carapils/Oatmeal/Barley Flakes/Wheat (choice of 1 of the 5)

Hops (Targeted IBU is 40):

You can use 1 or any combination of ONLY the following hops: Chinook, citra, amarillo, cascade and centennial.

No specific hop schedule.

Dry Hopping:

0-2oz using hops listed above.

Yeast

US-05 or WLP001 or Wyeast 1056

Finings:

Whirfloc, Irish Moss, Gelatin (all optional)

The stated 40 IBU requirement caused me some concern. I knew I'd have no way of guessing what the results would be like but that also nobody could argue that mine was or wasn't 40 IBU.Electric Hop Stand Pale Ale (batch #154)

10-A American Pale Ale

Author: Kal Wallner

Size: 12.0 gal @ 68 °F

Original Gravity: 1.052 (1.045 - 1.060)

Terminal Gravity: 1.010 (1.010 - 1.015)

Color: 7.53 (5.0 - 14.0)

Alcohol: 5.46% (4.5% - 6.2%)

Bitterness: No friggin' idea

Ingredients:

17.5 lb Domestic 2-Row Malt (89.7%)

1 lb Crystal Malt 50-60L (5.1%)

1 lb Carapils®/Carafoam® (5.1%)

1 Whirlfloc Tablet (Irish moss) - added during boil, boiled 15 min

2.6 oz Centennial Hops (11.1%) - added end boil

1.0 oz Cascade (6.0%) - added end boil

1.0 oz Chinook (11.4%) - added end boil

1.0 oz Citra Hops (11.1%) - added end boil

5.0 oz Centennial Hops (11.1%) - added +30 m into hop stand

1.5 oz Cascade (6.0%) - added +30 m into hop stand

2.0 oz Chinook (11.4%) - added +30 m into hop stand

2.0 oz Citra Hops (11.1%) - added +30 m into hop stand

12 g Fermentis Safale US-05 dry yeast (fermenter #1)

Wyeast 1056 American Ale slurry (fermenter #2)

1.0 oz Centennial Hops (11.1%) - added added dry to secondary fermenter

0.5 oz Cascade (6.0%) - added dry to secondary fermenter

1.0 oz Chinook (11.4%) - added dry to secondary fermenter

1.0 oz Citra Hops (11.1%) - added dry to secondary fermenter

Notes:

Add 500mg potassium metabisulphite to 20 gallons water to remove chlorine/chloramine (as required).

Water treated with brewing salts to: Ca=110, Mg=18, Na=16, Cl=50, S04=275

1.25 qt/lb mash thickness.

Single infusion mash @ 150F for 90 minutes.

Sparge with 168F water for 1-2 hrs.

Boil for 90 mins.

Adding first hops at flameout (0 mins). Whirlpool by gently stirring every ~10 mins. Lid off.

Drop temp to 170F and hold at 170F, add +30 min hops. Steep for 80 mins total then chill.

Aerate well (60 seconds with Fizz-X). Hydrate dry yeast for 30-60 mins until frothy prior to pitching.

Ferment at 68F. Dry hop for 7-10 days in secondary.

Rack to brite tank (secondary), crash chill to near freezing (if possible), add 1 tsp of unflavoured gelatine dissolved in a cup of hot distilled water per 5 gallons of beer, and let clear for 2-3 days.

Package as you would normally. I keg and carbonate on the low side (around 2 to 2.2 volumes of C02) to minimize carbonic bite and let the hop/malt flavour come through.

For more information on the complete brewing process steps used, see my Brew Day: Step by Step guide.

As it turns out, out of the 11 blind samples I tried (as a brewer I was part of the 'peoples choice'), mine was the hoppiest. After trying all 11 I was able to pick mine out without difficulties. I found it had the most hop flavour but was surprisingly low in hop aroma given the amount of post boil kettle hops and dry hops used. I'm not sure why. I would have expected more hop aroma. I think next time I'll try lowering the amount of hops at flameout to about 1/2 and add some first wort hops instead. I may also brew it as an IPA (higher ABV). There's still room for lots of experimentation.

Good question. I don't know. There's so little information about this out there and I'm definitely not an expert.I'm wondering if perhaps the hop stand was a bit too warm and more of the aromatic oils isomerized that way?

00:00 - Upon turning off the power the temp dropped from 210F to 208F almost immediately.

+01:00 - Added 6 oz of room temp hops. Temp dropped to 206F.

+03:00 - Temp at 203F

+08:00 - Temp at 196F

+13:00 - Temp at 192F

+25:00 - Temp at 182F

+30:00 - Temp at 178F. Added second dose (10 oz) of hops.

+30:00 to 80:00 - At this point I set the boil kettle to 170F to avoid going any lower. The temperature settled out at 170F and stayed there for the rest of the hop stand with the boil kettle element firing periodically. The firing of the element does not create a violent boil or stir, just enough movement to keep the hops moving around without me having to stir as much.

What do you consider the "flavor stand" range?

What's the thought behind lowering the temp on the second stand?

Enter your email address to join: