FloppyKnockers

Well-Known Member

A while ago I made a couple tap handles and created a thread about it here. The problem was I was pretty picture deficient in the Duff handle. Recently I had an opportunity to do another one of the same so I made use of the chance and took plenty of pictures and decided to create a new thread for both prosperity and assistance to others...enjoy.

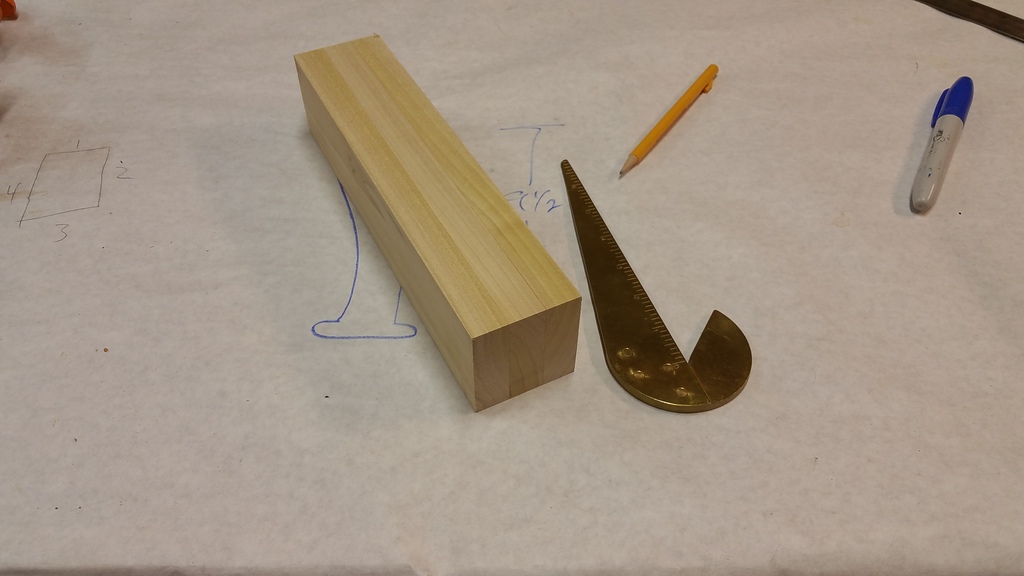

The very beginning. A 1 x 3 piece of poplar cut into 3, 10 1/2" pieces for glue-up.

The three pieces.

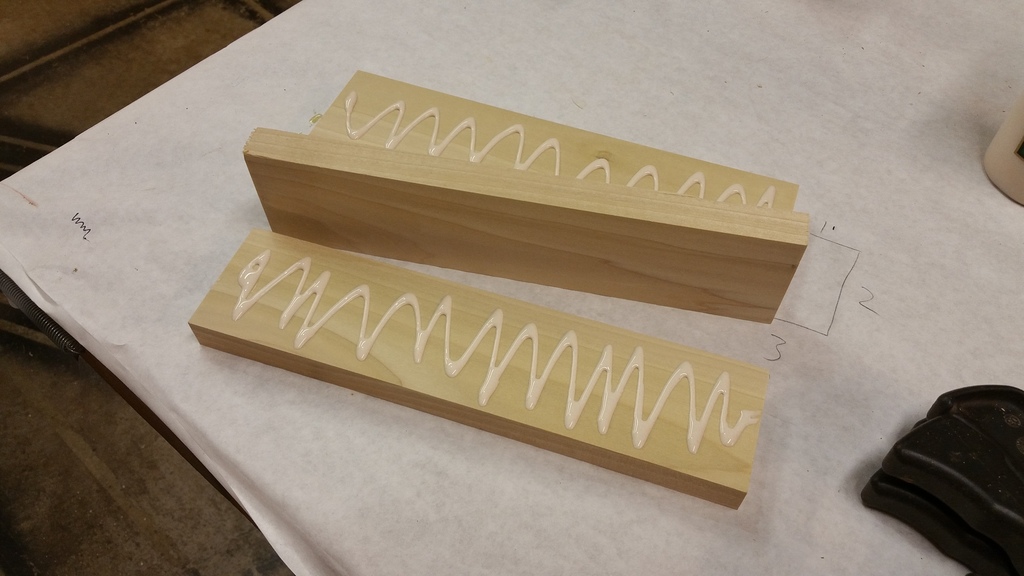

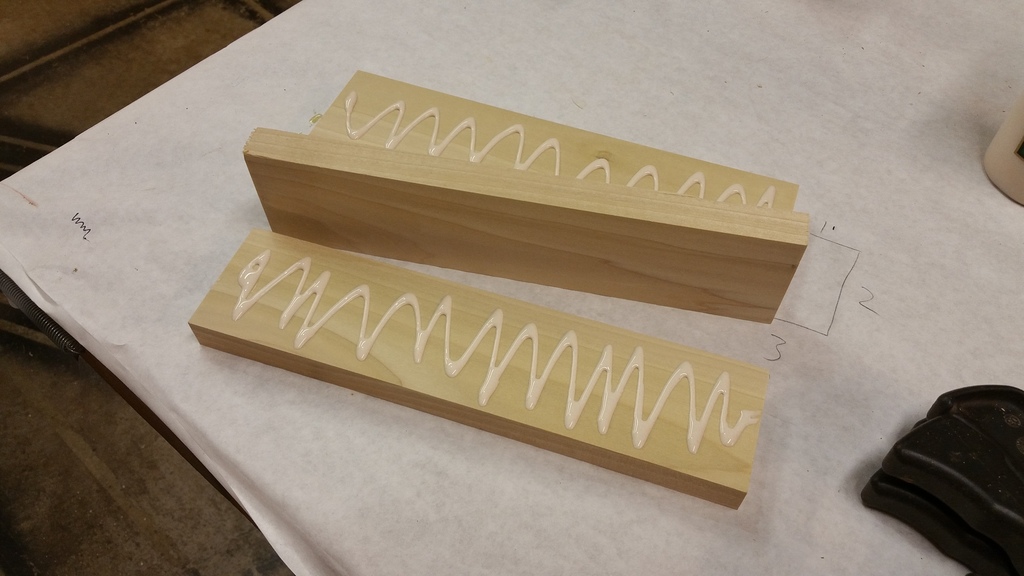

The three pieces with plenty of glue. Can't skimp on this. Better too much than not enough.

Glue all spread and all clamped up to cook overnight. After it's dry and cured I will cut the ends square, scrape the glue, and mark it for the lathe.

______________________________________________________________

Day 2

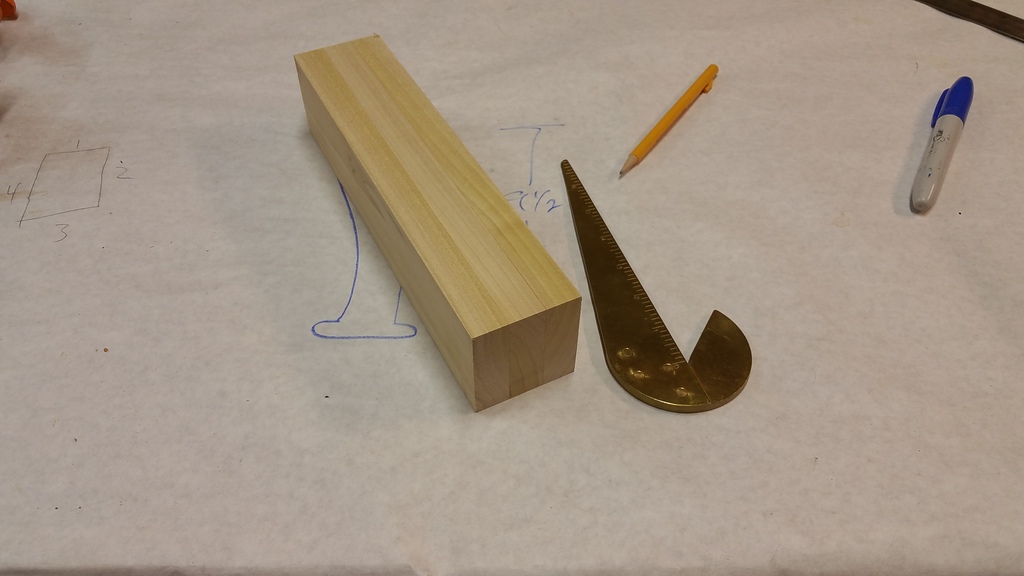

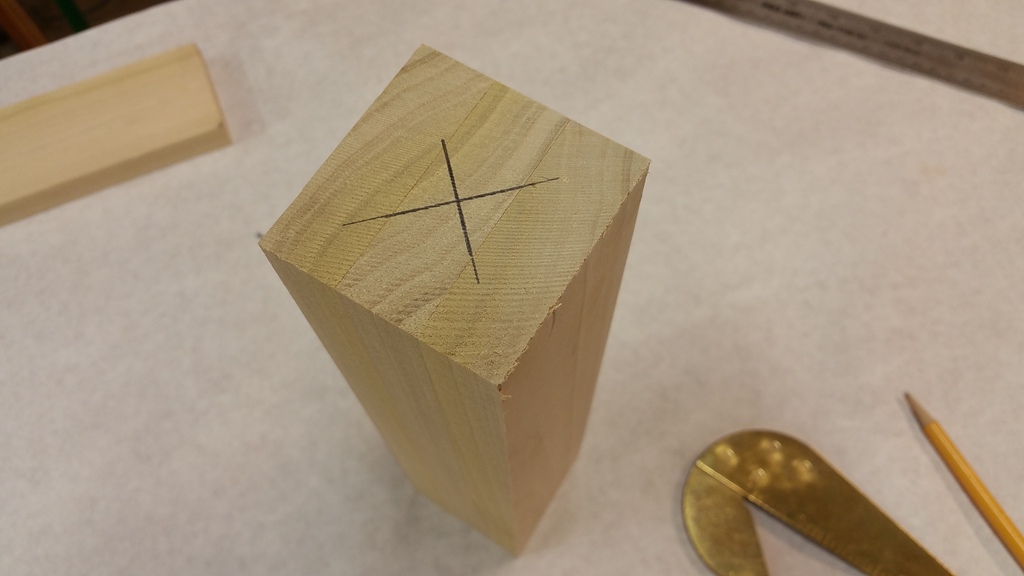

Here we have the blank squared up ready to be marked for centers. It now measures about 2 1/4 square by 10 1/4.

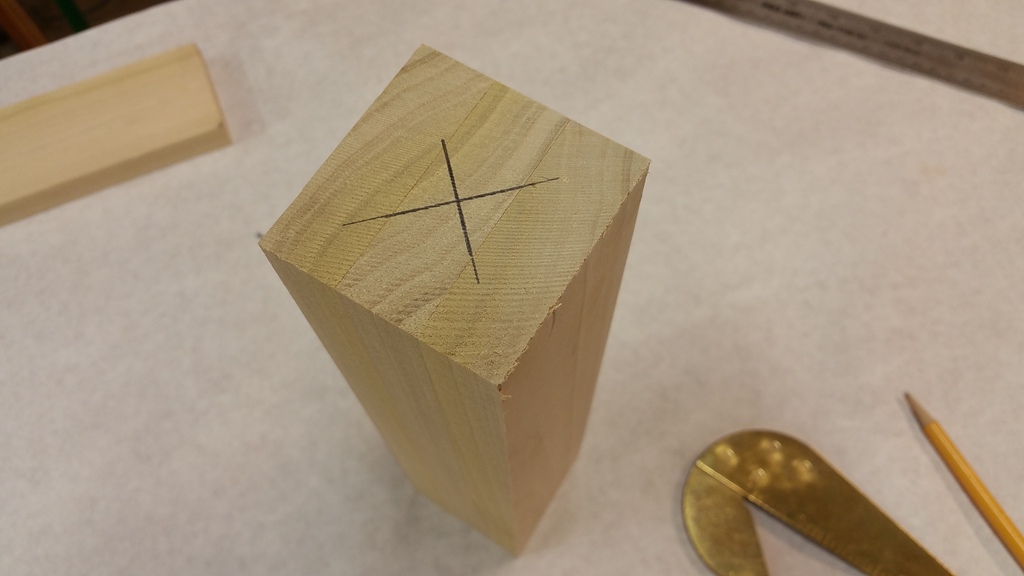

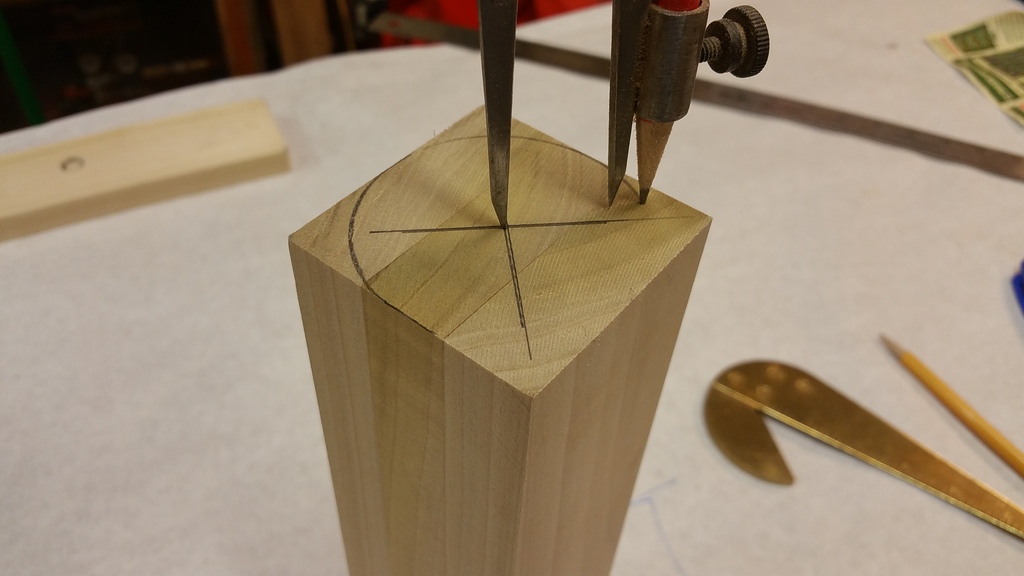

Marked for center on both sides.

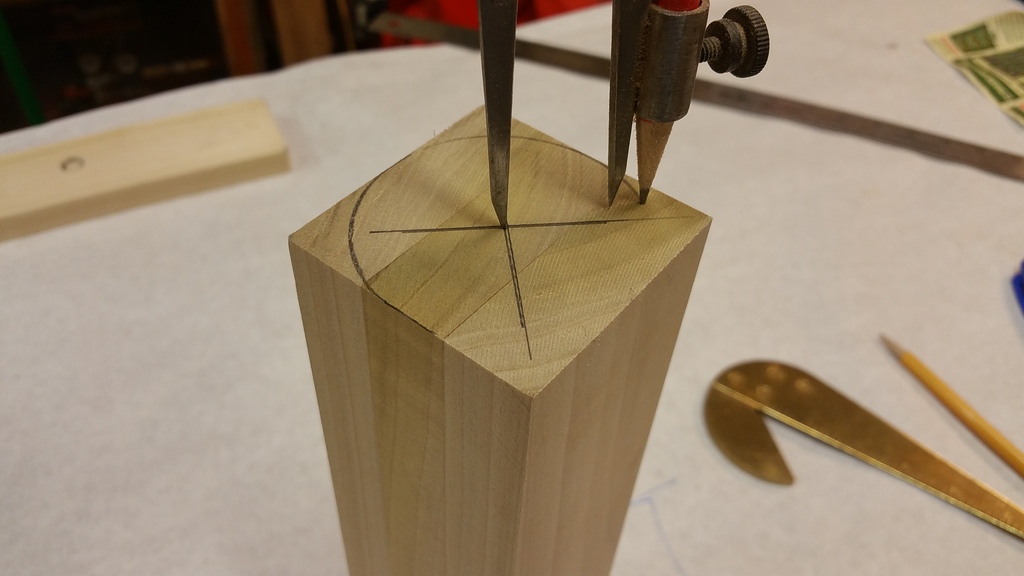

Next I drew the biggest circle that would fit on the end. This will tell me the maximum diameter that can be achieved on the lathe.

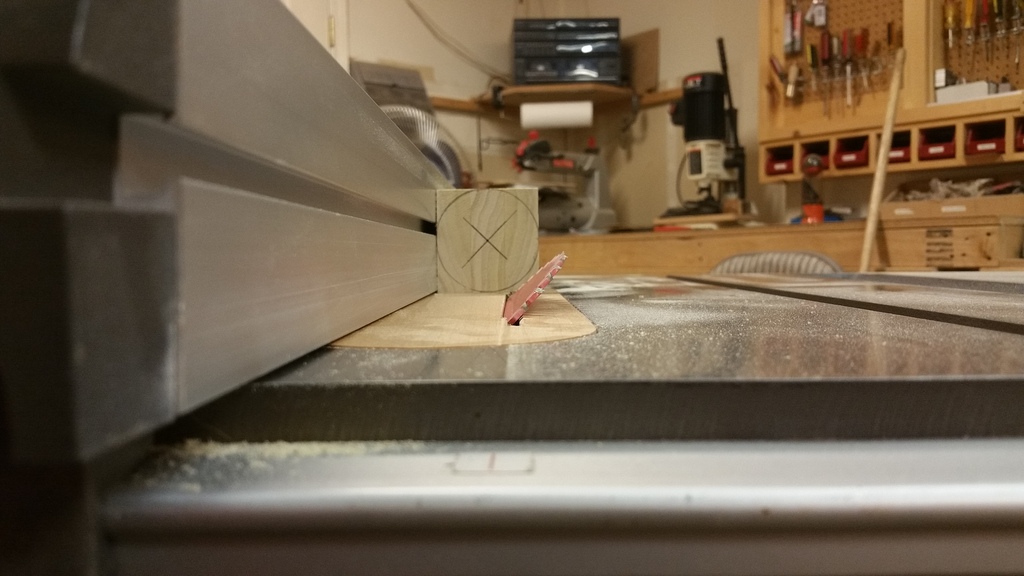

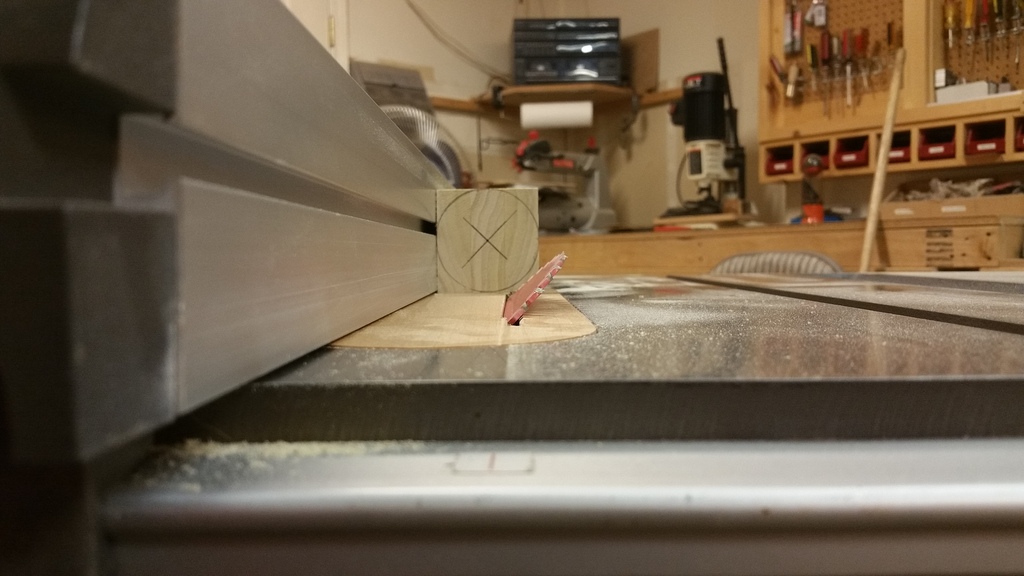

With the blade tipped at 45° I will knock off the corners to save some time at the lathe.

Here it is ready to go on the lathe. I will turn it tomorrow and if I can I will try to shoot video of that.

______________________________________________________________________________

Day 3

Back in the shop. Got some short ribs on the grill, hanging with the wife, and sipping on some cold ones. Time to turn the handle...

[ame]

The one thing I couldn't do on the lathe was the very top. Here I spent a bit of time hand sanding to get the top smooth.

The very beginning. A 1 x 3 piece of poplar cut into 3, 10 1/2" pieces for glue-up.

The three pieces.

The three pieces with plenty of glue. Can't skimp on this. Better too much than not enough.

Glue all spread and all clamped up to cook overnight. After it's dry and cured I will cut the ends square, scrape the glue, and mark it for the lathe.

______________________________________________________________

Day 2

Here we have the blank squared up ready to be marked for centers. It now measures about 2 1/4 square by 10 1/4.

Marked for center on both sides.

Next I drew the biggest circle that would fit on the end. This will tell me the maximum diameter that can be achieved on the lathe.

With the blade tipped at 45° I will knock off the corners to save some time at the lathe.

Here it is ready to go on the lathe. I will turn it tomorrow and if I can I will try to shoot video of that.

______________________________________________________________________________

Day 3

Back in the shop. Got some short ribs on the grill, hanging with the wife, and sipping on some cold ones. Time to turn the handle...

[ame]

The one thing I couldn't do on the lathe was the very top. Here I spent a bit of time hand sanding to get the top smooth.

Last edited: