marcb

Well-Known Member

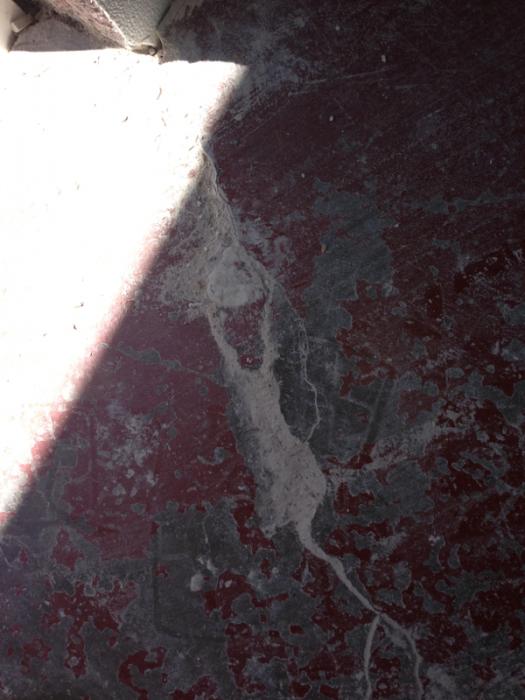

Here's the boil kettles. 200 liter, dished bottom. Tri Clover sanitary ferrules welded from the inside for outlet, thermowell, two elements, and a tangential inlet for whirl pooling. Lids have an additional ferrule for a yet-to-be-designed/built auto sparge assembly and a spray ball for cleaning.

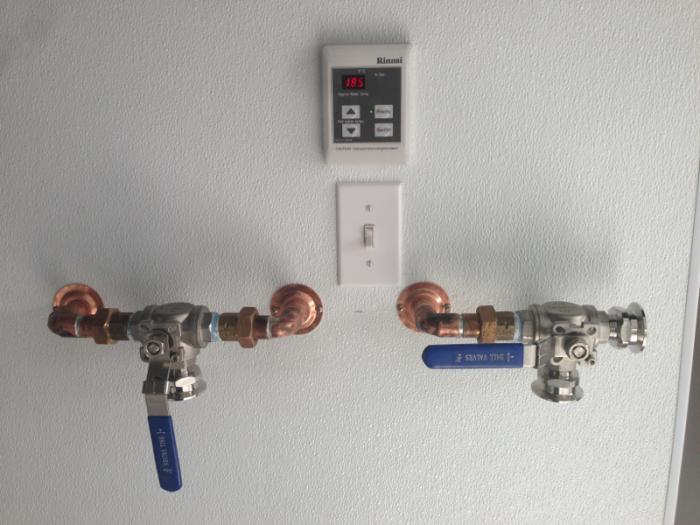

Marc, the last pic is the "mountain of stainless" as you called it I have to move so Christy can park in the garage again. I HAVE to get Humberto over to build my storage area...

Evan,

Thanks for posting the pics and putting the watchdog on guarding the kettles!