So after getting some advice here on setting my barley crusher (which was great and appreciated) I found myself with another dilemma. The drill which I had gotten specifically to run it wouldn't turn it. This is the drill I had purchased and which I now need to replace after a lot of hand cranking this weekend:

http://www.menards.com/main/tools-h...lt-cordless-drill-driver/p-1974668-c-9072.htm

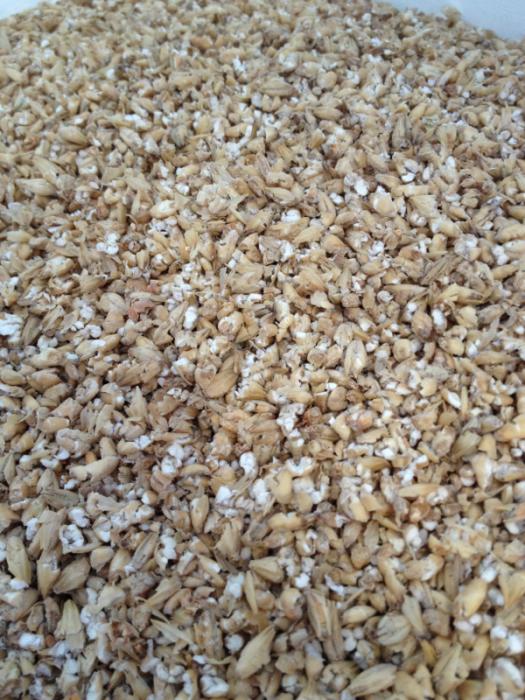

It wasn't cutting it. I tried a little test on it last night, putting a half pound of 2-row in there, setting it to the max torque, and it couldn't push anything through at all. It couldn't move. Just sat there stupefied.

So I was thinking about something like one of these two:

http://www.menards.com/main/tools-h...erforce-1-2-hammer-drill/p-1474371-c-9072.htm

http://www.menards.com/main/tools-h...e-speed-reversible-drill/p-1474370-c-9072.htm

The reading I have done says go for corded over cordless to get the torque you need. I don't have much in the way of tools around my house right now mainly because they aren't needed at this point and I'm renting. Would either of those be good choices? Would they work? Should I look for something else?

http://www.menards.com/main/tools-h...lt-cordless-drill-driver/p-1974668-c-9072.htm

It wasn't cutting it. I tried a little test on it last night, putting a half pound of 2-row in there, setting it to the max torque, and it couldn't push anything through at all. It couldn't move. Just sat there stupefied.

So I was thinking about something like one of these two:

http://www.menards.com/main/tools-h...erforce-1-2-hammer-drill/p-1474371-c-9072.htm

http://www.menards.com/main/tools-h...e-speed-reversible-drill/p-1474370-c-9072.htm

The reading I have done says go for corded over cordless to get the torque you need. I don't have much in the way of tools around my house right now mainly because they aren't needed at this point and I'm renting. Would either of those be good choices? Would they work? Should I look for something else?