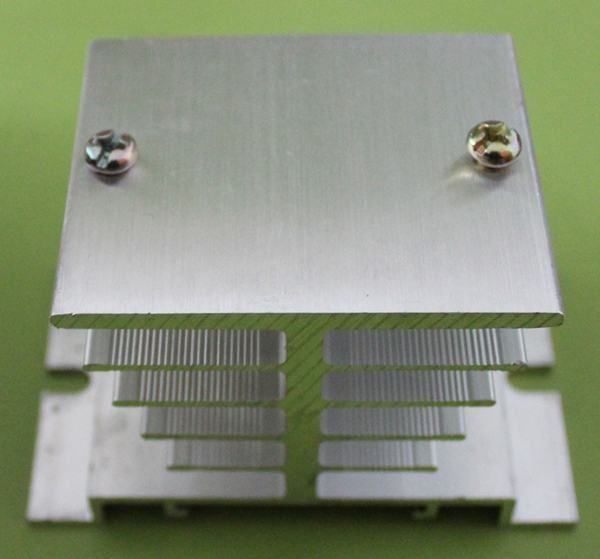

Would one not expect that the supplied DIN mounted heat sink for the SSR should be designed to allow correct operation of the SSR. A big factor would also to not max out your SSR, go for a 40A for a 20A load. I have one 40A SSR mounted on a DIN heatsink inside my box, under load the back of the box is barely warm to the touch.

As long as you have a heat sink to mount to the SSRs, you're good. If you mount a SSR to some DIN rail, it isn't going to last a long time. Switching a 20amp load is a lot of energy... that creates alot of heat, it needs to go somewhere.