TheCarbinator

New Member

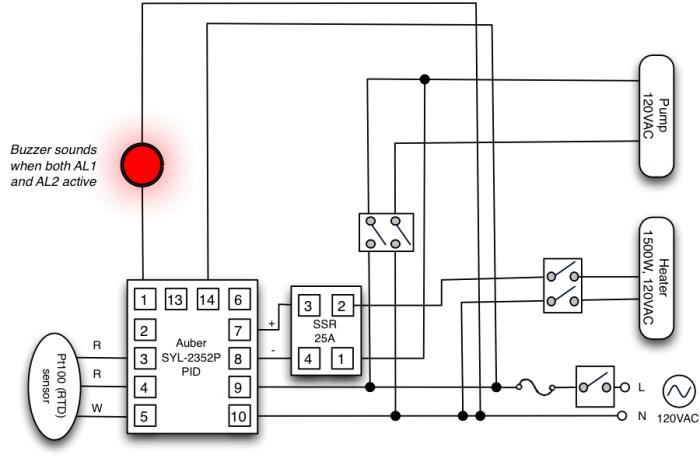

So I bought the following items a couple of weeks ago to make up my HERMS temp controller.

Auber PID Model: SYL-2352P

http://www.auberins....1&products_id=4

Temp probe (PT 100)

http://www.auberins....products_id=261

Also bought the appropriate SSR and heatsink to suit.

I had them hooked up by an electrician while carefully reading the instructions.

Then when I turn it on, the temperature is showing (as far as I can work out) minus two hundred and something degrees.

That was after I changed the settings to celcius.

Then I swapped the two red wires on terminals 3 and four.

Now it is showing 636 degrees celcius (as in photo)

Has anyone come across this?

Any advice would be great!

Cheers

Andrew

Auber PID Model: SYL-2352P

http://www.auberins....1&products_id=4

Temp probe (PT 100)

http://www.auberins....products_id=261

Also bought the appropriate SSR and heatsink to suit.

I had them hooked up by an electrician while carefully reading the instructions.

Then when I turn it on, the temperature is showing (as far as I can work out) minus two hundred and something degrees.

That was after I changed the settings to celcius.

Then I swapped the two red wires on terminals 3 and four.

Now it is showing 636 degrees celcius (as in photo)

Has anyone come across this?

Any advice would be great!

Cheers

Andrew