GreenEnvy22

Well-Known Member

- Joined

- Sep 17, 2015

- Messages

- 172

- Reaction score

- 155

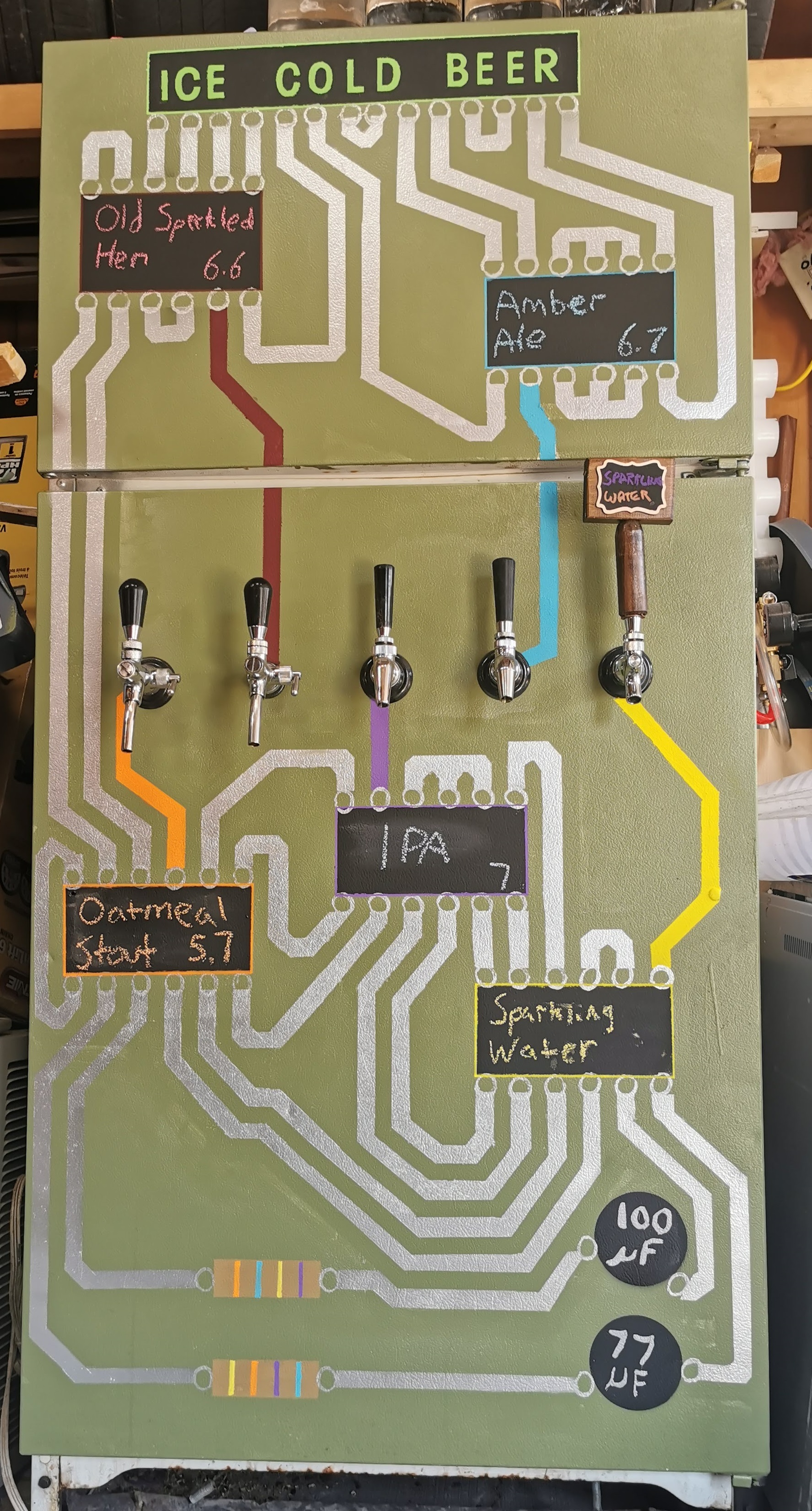

I've just had a plain white old beer fridge that I had converted into a kegerator.

I decided I want to paint it to make it look better. I'm an IT guy so I got the idea of doing a circuit board look, with the various chips on the board being chalkboard labels.

I've already painted the fridge green, haven't done anything else yet but wanted to get feedback on the general concept.

I'm a horrible artist, and even worse in MS-paint, but I drew up this rough concept, thoughts?

Now:

Concept:

I decided I want to paint it to make it look better. I'm an IT guy so I got the idea of doing a circuit board look, with the various chips on the board being chalkboard labels.

I've already painted the fridge green, haven't done anything else yet but wanted to get feedback on the general concept.

I'm a horrible artist, and even worse in MS-paint, but I drew up this rough concept, thoughts?

Now:

Concept: