Just bought myself a Chinese TIG welder - just a 150A DC with HF, but should be perfect for my needs for brewing equipment.

One thing I have noticed though is there are a number of similar units that look to use the same PCB but with different features.

For example my unit has control for amps and post flow duration, but no digital amp setting display, switch for MMAW/TIG, or option to use a foot pedal.

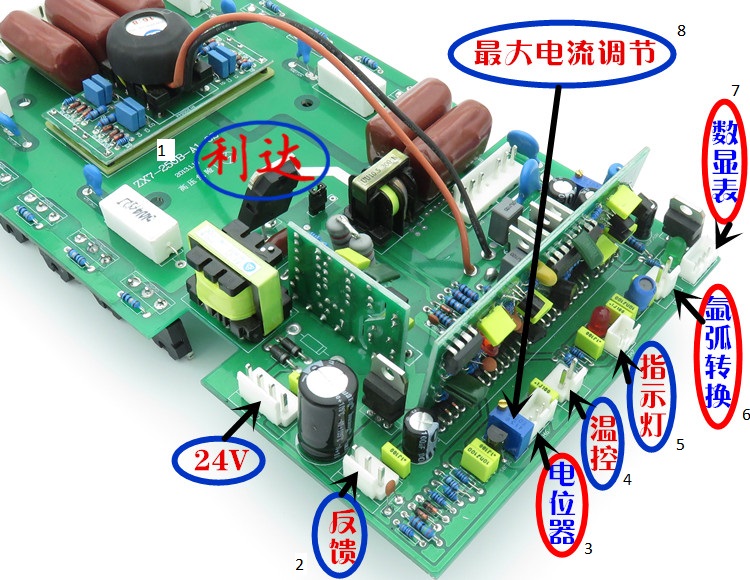

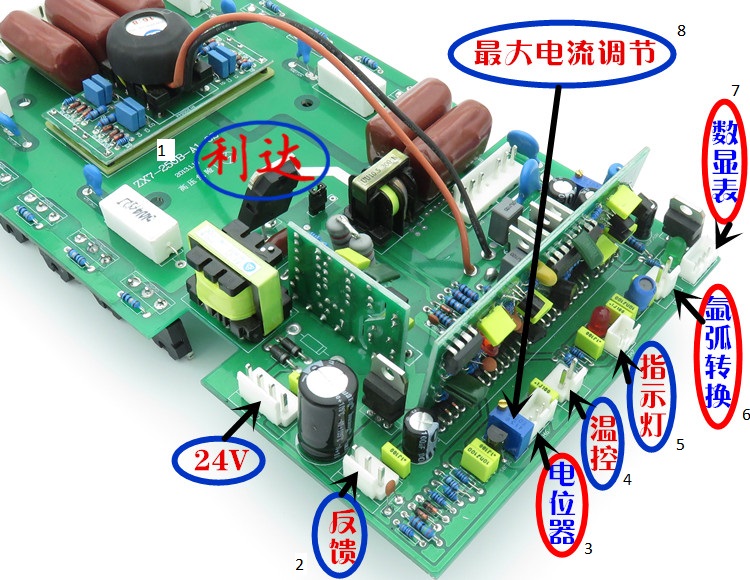

I found a notated picture of the PCB online, problem is it is in Chinese!

Can anyone translate the attached picture? I have numbered them 1-8 to avoid confusion.

Cheers

One thing I have noticed though is there are a number of similar units that look to use the same PCB but with different features.

For example my unit has control for amps and post flow duration, but no digital amp setting display, switch for MMAW/TIG, or option to use a foot pedal.

I found a notated picture of the PCB online, problem is it is in Chinese!

Can anyone translate the attached picture? I have numbered them 1-8 to avoid confusion.

Cheers