Klickmania

Well-Known Member

I've been kegging for about a year now and this has just recently become a problem. For some reason a lot of my beers have been ridiculously foamy. I chalked the first few batches up to over carbing because I tried the 30 psi and shake method. I reverted back to the set and forget method which I thought would solve the problem, but I'm still getting foamy pours. If I'm pouring a few beers in a row the second pint isn't nearly as foamy as the first. After thinking about it some, I did some investigating. I noticed I was getting air gaps in my beer lines near the connectors after I let it sit for a while.

I recently added a Co2 diffuser block and a second tap line but this started with just a single tap line. I usually carb and serve at or around 10 PSI and 35-40 degrees F (no temp controller yet), and that usually gets me around 2.0 to 2.3 volumes. I also had an issue with a 5 gallon batch not carbonating after close to 2 weeks at 10 psi. And I mean, flat as can be after 10 days on the gas. It showed no signs whatsoever of carbonation, which I though was weird. I swapped out to a spare tank I had laying around that I'm still using now. That tank currently carbonated and is now serving 10 gallons of foamy first pour beers. I also have 5 foot beer lines if that matters. I've used the online balancing calculators and my system is pretty balanced from what I can tell.

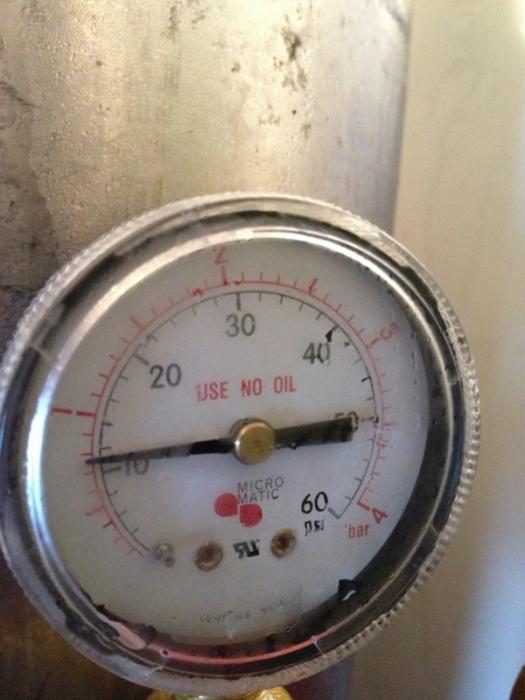

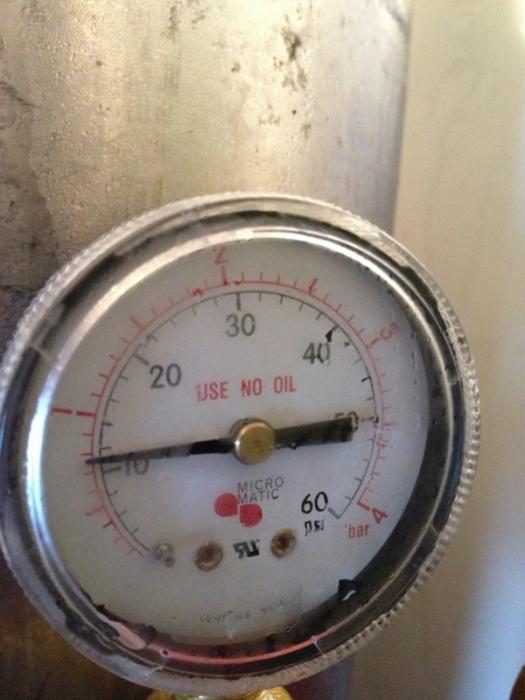

FYI I have a dual stage regulator on my five pound tank. All this has happened with the main gauge reading near or under the red portion, but I was still getting 10-11 psi at the line regulator. I thought as long as I had the correct psi going into the keg/diffuser I wouldn't have any issues until I ran out of gas.

My question is, what is causing the air gaps in my beer lines?? I'm pretty sure that's why it's foaming so bad. Thanks ahead for any input.

Here's what my lines look like a few minutes after I pour a pint, as well as my current pressure readings.

I recently added a Co2 diffuser block and a second tap line but this started with just a single tap line. I usually carb and serve at or around 10 PSI and 35-40 degrees F (no temp controller yet), and that usually gets me around 2.0 to 2.3 volumes. I also had an issue with a 5 gallon batch not carbonating after close to 2 weeks at 10 psi. And I mean, flat as can be after 10 days on the gas. It showed no signs whatsoever of carbonation, which I though was weird. I swapped out to a spare tank I had laying around that I'm still using now. That tank currently carbonated and is now serving 10 gallons of foamy first pour beers. I also have 5 foot beer lines if that matters. I've used the online balancing calculators and my system is pretty balanced from what I can tell.

FYI I have a dual stage regulator on my five pound tank. All this has happened with the main gauge reading near or under the red portion, but I was still getting 10-11 psi at the line regulator. I thought as long as I had the correct psi going into the keg/diffuser I wouldn't have any issues until I ran out of gas.

My question is, what is causing the air gaps in my beer lines?? I'm pretty sure that's why it's foaming so bad. Thanks ahead for any input.

Here's what my lines look like a few minutes after I pour a pint, as well as my current pressure readings.