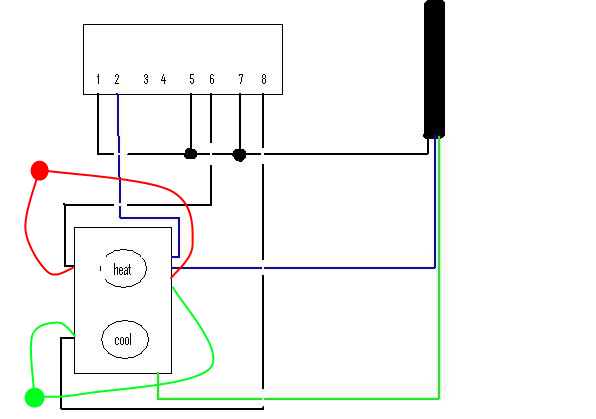

For those of you adding lamps or LEDs to signify cooling/heating, where in the circuit are you adding them? Parallel or in series? Before or after the receptacle?

In an AC circuit like this, the lamp gets wired in parallel. I expect that most people that put in an indicator wire it before the receptacle so that it shows what the control box is doing regardless to anything plugged into the receptacle.