yoop89

Well-Known Member

Starting a thread to keep me focused and get some insights on some of the processes that I have yet to do. We closed on our house this past 4th of July and progress has been slow and steady getting stuffed fixed up and organized. I have found some spare time to get the basement/brewery/bar cleaned up and modified slightly

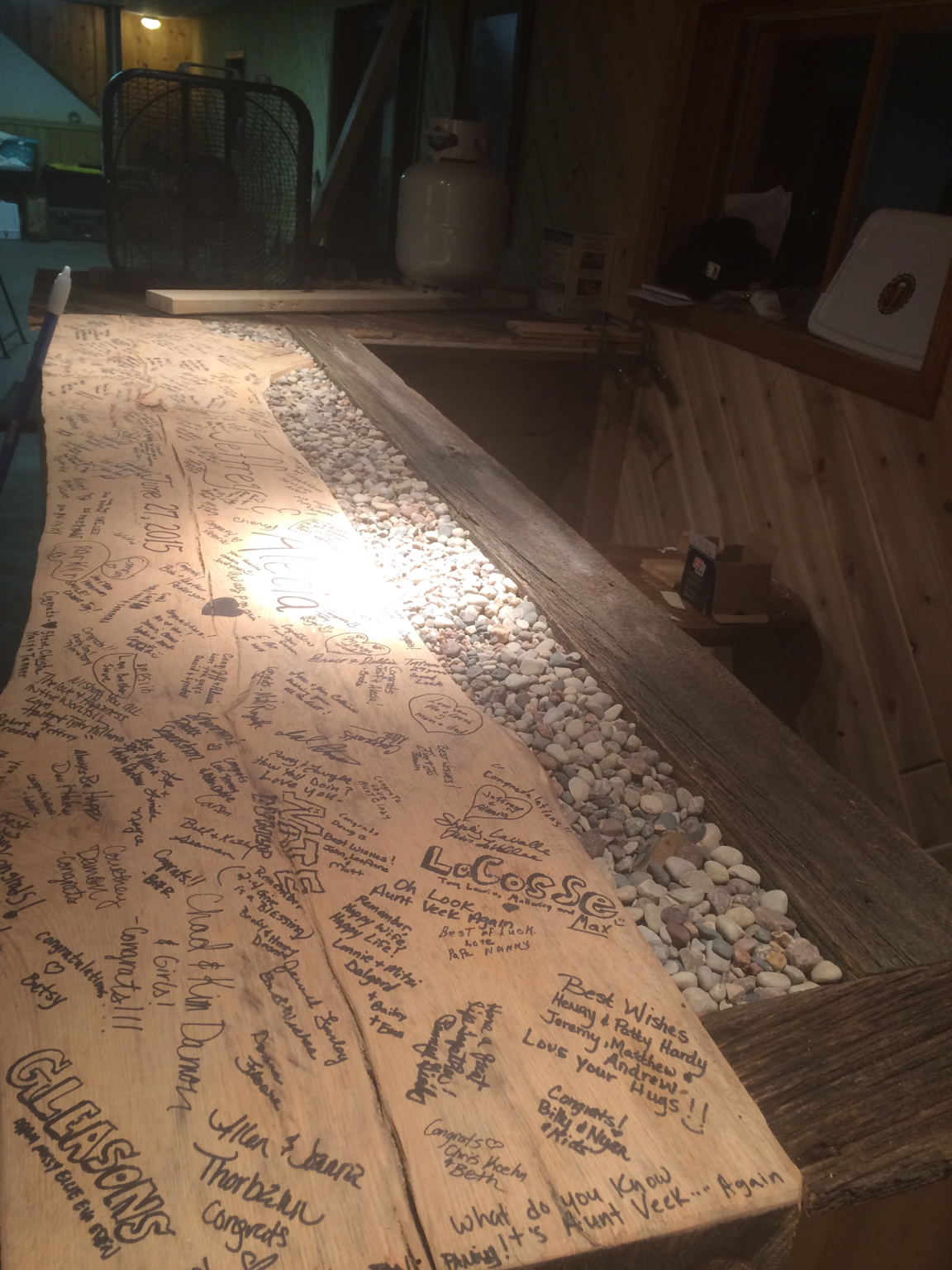

This is the bar "project" that was already in the house when we moved in.

Loved the hardwood floor bartop but it was unfinished, rough and falling apart. The rest of the bar is wrapped in cedar tounge and groove.

After a little bit of demo and cutting I am here, with the new bartop waiting patiently.

As of last night I just need to redo some framing to support the 6" slab of Oak and clean up some of my cuts. Once its all mounted I plan on pouring the whole bar with resin. Thats where my first question comes in. Has anyone here done it? Ive seen many bar tops that have been poured but never actually seen it done. I plan on running to menards after work to grab a few boards and the epoxy kit.

My plan was to mix up a small batch and brush on to fill in cracks and prepare the surface for the pour then mix up the rest the following day(after giving the first thin coat time to cure).

After the top is poured I plan on moving to the back side and installing our wine fridge and starting my kegerator build. Plans are for a 4 tap tower with this guy to keep stuff cool.

Its an old commercial fridge from Starbucks with enough space for 4 cornies and itll fit behind the bar

Hopefully I will be updating this with more pics soon as work progresses!!

This is the bar "project" that was already in the house when we moved in.

Loved the hardwood floor bartop but it was unfinished, rough and falling apart. The rest of the bar is wrapped in cedar tounge and groove.

After a little bit of demo and cutting I am here, with the new bartop waiting patiently.

As of last night I just need to redo some framing to support the 6" slab of Oak and clean up some of my cuts. Once its all mounted I plan on pouring the whole bar with resin. Thats where my first question comes in. Has anyone here done it? Ive seen many bar tops that have been poured but never actually seen it done. I plan on running to menards after work to grab a few boards and the epoxy kit.

My plan was to mix up a small batch and brush on to fill in cracks and prepare the surface for the pour then mix up the rest the following day(after giving the first thin coat time to cure).

After the top is poured I plan on moving to the back side and installing our wine fridge and starting my kegerator build. Plans are for a 4 tap tower with this guy to keep stuff cool.

Its an old commercial fridge from Starbucks with enough space for 4 cornies and itll fit behind the bar

Hopefully I will be updating this with more pics soon as work progresses!!