Starting to feel more confused the more I read. Seems like some people are using 1/2", some 1/4", some have mixed pieces. And there is me.. a total rookie with building anything propane related and not wanting to mess this up.

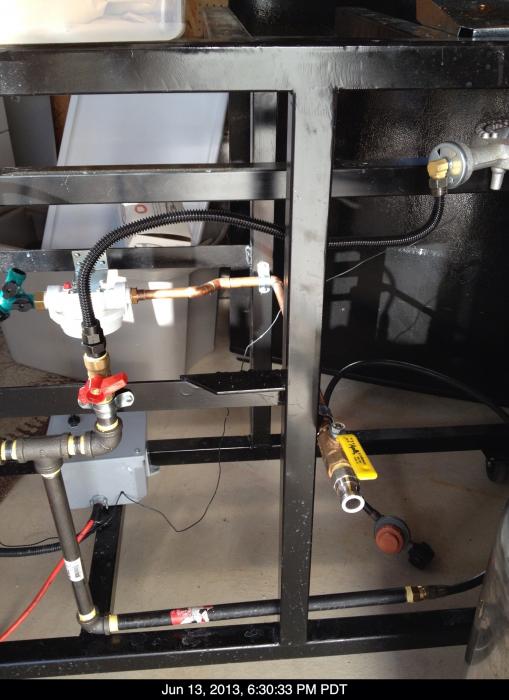

The build is pretty simple. Three BG-14 burners. All manually controlled.

Looking to build a manifold likely out of black steel pipe to attach to the brewstand.

I was thinking of doing a 90* off the burner but it looks like that might add alot of cost ($15 for each fitting), so I'll likely just run the hose off the burner, down to a needle valve that will attach to the manifold, and then a regulator to attach to the bottle.

Could someone help link me to all the parts needed for this?

The build is pretty simple. Three BG-14 burners. All manually controlled.

Looking to build a manifold likely out of black steel pipe to attach to the brewstand.

I was thinking of doing a 90* off the burner but it looks like that might add alot of cost ($15 for each fitting), so I'll likely just run the hose off the burner, down to a needle valve that will attach to the manifold, and then a regulator to attach to the bottle.

Could someone help link me to all the parts needed for this?