smoothlarryhughes

Well-Known Member

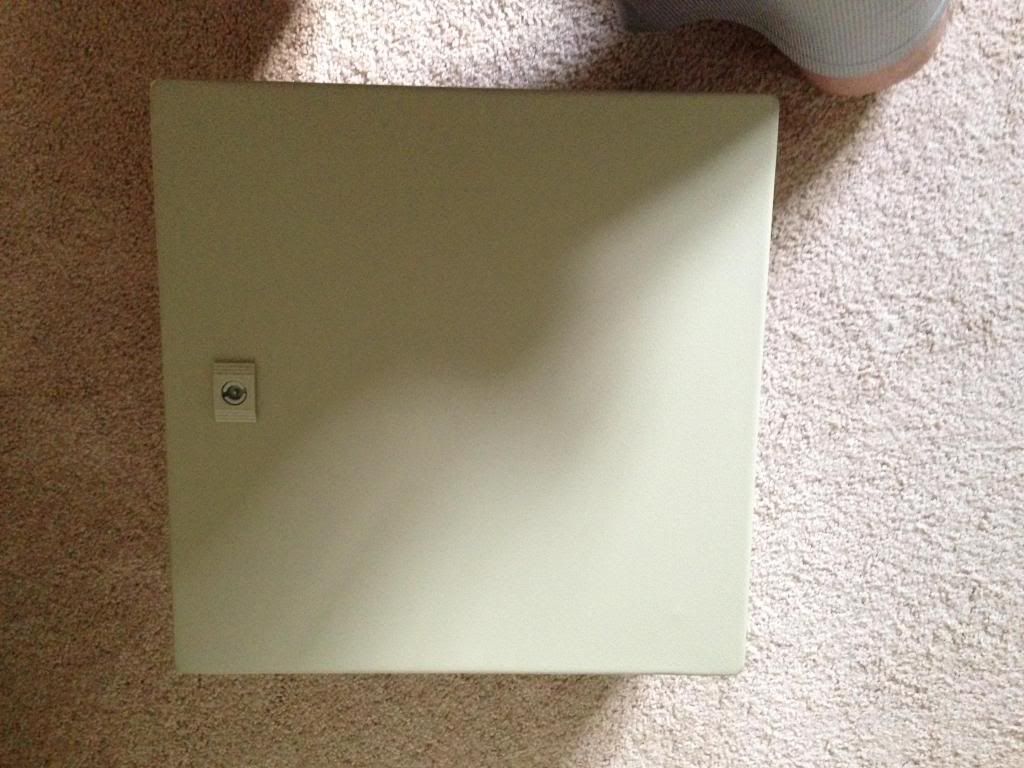

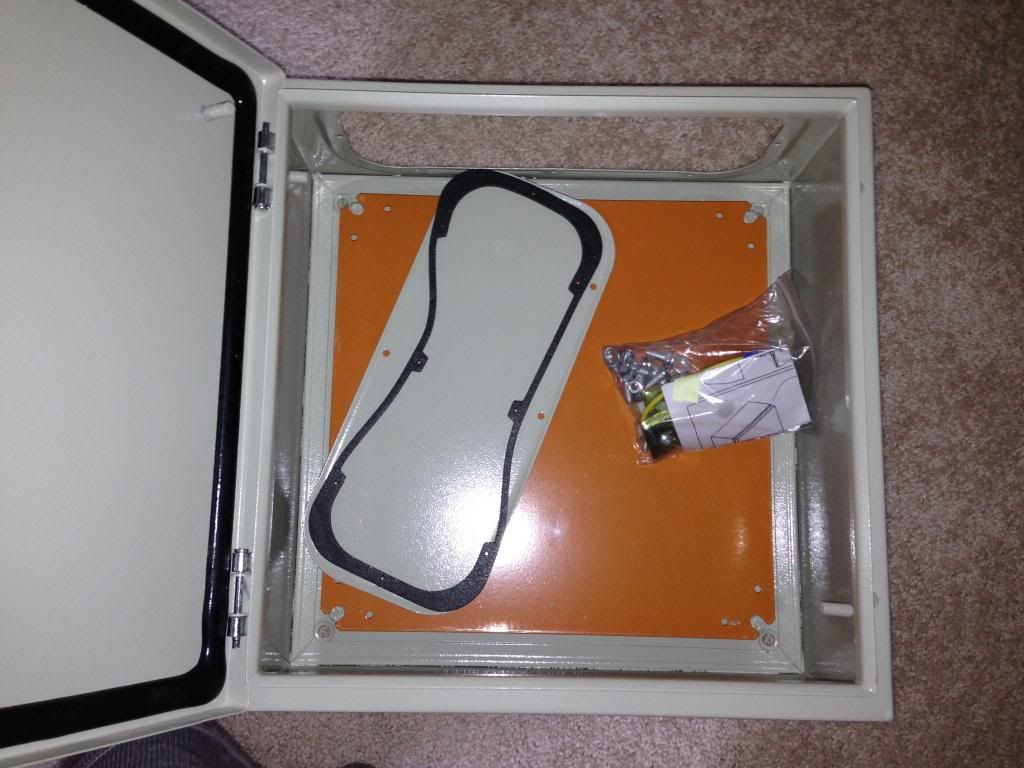

I was going to build this control panel about a year ago, but I never followed through. In my original thread PJ gave me this wiring diagram, and since I haven't really been planning for awhile, I have a few questions, and I am wondering if a few things can be added to this.

First off, does anyone have a diagram to add a main power on/off switch to cut/give power to the entire panel?

2nd, should I add a second PID to monitor mash temp (once I switch to herms)? I plan on using my cooler MLT at first. I want to build the panel to use for HLT heating, use the cooler to mash, then use the panel for the BK.

From what I can tell SW7 is used to give power to the PID and timer. Is this correct?

I also came across this wiring diagram, which looks to give me info on wiring a key on/off switch.

Also, any advise on gauge wires used for these diagrams? Sorry for all the questions.

Thanks!

First off, does anyone have a diagram to add a main power on/off switch to cut/give power to the entire panel?

2nd, should I add a second PID to monitor mash temp (once I switch to herms)? I plan on using my cooler MLT at first. I want to build the panel to use for HLT heating, use the cooler to mash, then use the panel for the BK.

From what I can tell SW7 is used to give power to the PID and timer. Is this correct?

I also came across this wiring diagram, which looks to give me info on wiring a key on/off switch.

Also, any advise on gauge wires used for these diagrams? Sorry for all the questions.

Thanks!