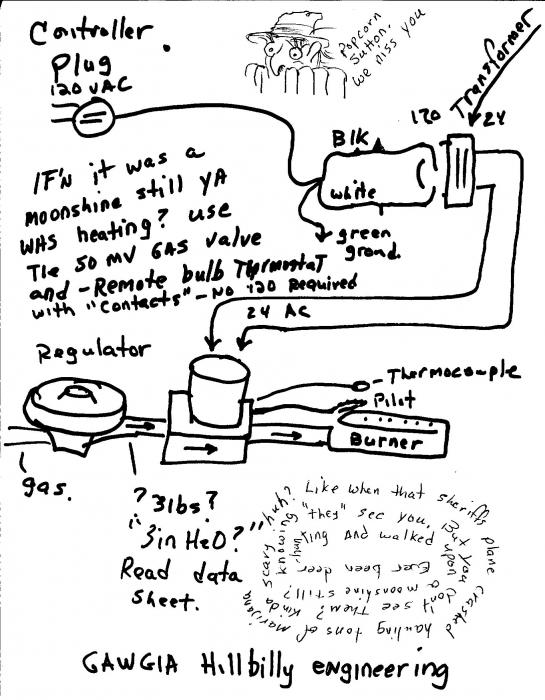

Using a Honeywell Furnace control valve, has the LP kit with the orifice and spring adjustor, this one runs on 24vac to turn on and off, has a thermopile to detect flame, has a pilot light tube, requires a external regulator to reduce incoming gas pressure to 3psi.

HOW IT WORKS, when you turn it to Pilot and depress it flows gas to the pilot burner, once the pilot is lit, the thermocouple- thermopile converts the flame to 50 millivolts and returns the generated electricity to the valve where it "allows" the valve to continue pilot gas and flame. You rotate the blue knob to BURNER. Then when you apply 24 volts to the two terminals, if it has pilot voltage, it turns on the valve, simple and safe.

To connect it to a PID off ebay you use the "relay" contacts, connect a 24vac transformer one leg to the valve, other to the relay in the PID, take the switched leg of the PID relay to the other valve terminal. When the relay makes in the PID calling for "heat" it switches the valve on. THE thermocouple, rtd, or temp sensor from the PID attached in a thermowell in the cook pot, it senses the temperature and turns the valve on and off regulating heat.

THIS one here is tied to a JUNK flame burner from a old hot water heater, to adjust the flame on the unit you take the cap off the "low pressure" adjustment on the Honeywell valve, turn the output pressure up, or down to adjust the flame from the burner, you want a decent flame but not a jet engine sound. USE common sense, too much flame and it "overshoots" the temperature setpoint in the PID control.

Need more help? if I am sitting around I will be glad to talk you through it.

WHO am I? I'm a 56 year old IBEW Electrician-instrument tech from the Chattanooga area with a lifetime of experience, I do not know everything, I am not familiar with everything and things are changing daily. I am a fast study on controls and instrumentation thou. I have a full fab shop here. Am not aging too well thou.

If I had a "WAD of money" and the space I'd have three of these controls, a three pot burner system. If you got a wad of money and need more help than I can provide in emails I can be had, or rented. I'd love to come drink your beer and leave with some of your money.

HOW IT WORKS, when you turn it to Pilot and depress it flows gas to the pilot burner, once the pilot is lit, the thermocouple- thermopile converts the flame to 50 millivolts and returns the generated electricity to the valve where it "allows" the valve to continue pilot gas and flame. You rotate the blue knob to BURNER. Then when you apply 24 volts to the two terminals, if it has pilot voltage, it turns on the valve, simple and safe.

To connect it to a PID off ebay you use the "relay" contacts, connect a 24vac transformer one leg to the valve, other to the relay in the PID, take the switched leg of the PID relay to the other valve terminal. When the relay makes in the PID calling for "heat" it switches the valve on. THE thermocouple, rtd, or temp sensor from the PID attached in a thermowell in the cook pot, it senses the temperature and turns the valve on and off regulating heat.

THIS one here is tied to a JUNK flame burner from a old hot water heater, to adjust the flame on the unit you take the cap off the "low pressure" adjustment on the Honeywell valve, turn the output pressure up, or down to adjust the flame from the burner, you want a decent flame but not a jet engine sound. USE common sense, too much flame and it "overshoots" the temperature setpoint in the PID control.

Need more help? if I am sitting around I will be glad to talk you through it.

WHO am I? I'm a 56 year old IBEW Electrician-instrument tech from the Chattanooga area with a lifetime of experience, I do not know everything, I am not familiar with everything and things are changing daily. I am a fast study on controls and instrumentation thou. I have a full fab shop here. Am not aging too well thou.

If I had a "WAD of money" and the space I'd have three of these controls, a three pot burner system. If you got a wad of money and need more help than I can provide in emails I can be had, or rented. I'd love to come drink your beer and leave with some of your money.