NautiDogBrewingCo.

NautiDogBrewingCo

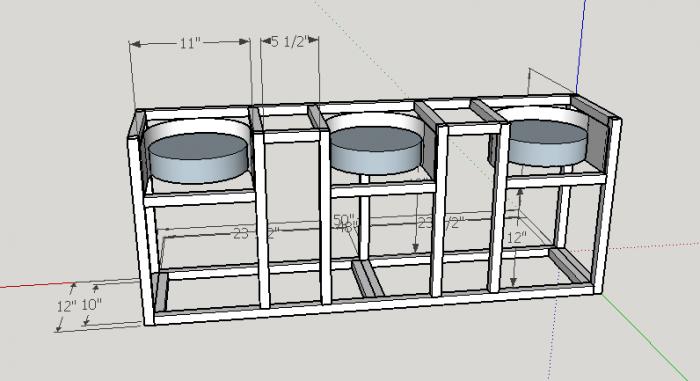

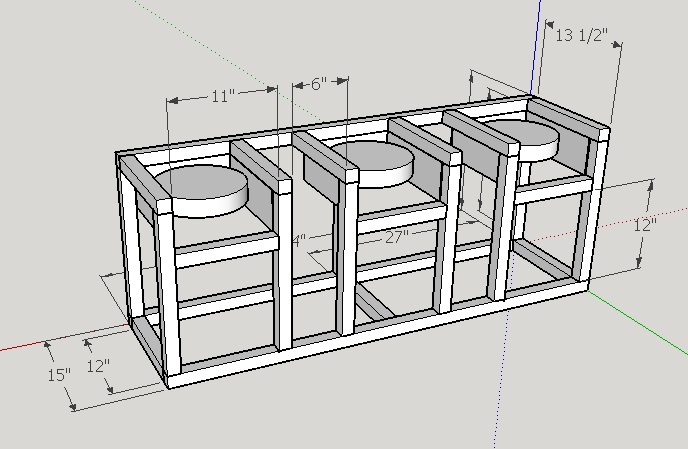

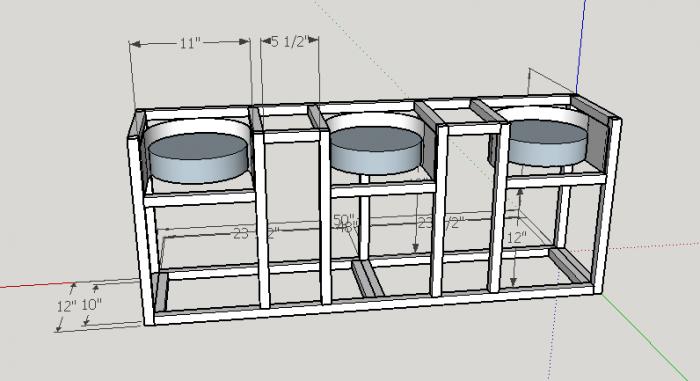

I am starting what will be the very slow process of building a single tier brew stand. I have come across some steel on the ultra cheap and will be enlisting the help of family and friends to teach me and lend me the equipment to weld it.

The steel I acquired is 1x1 18 gauge and 1x1 11 gauge. The majority of it is 18 gauge. Based on my calculations, I will have to buy a few steel pieces to complete the project. Is the 18 gauge strong enough?

I want the stand to be 3 burner, using BG14 burners powered by standalone propane tank(s). Maybe BG12 burners if it is determined that they would be powerful enough for 5 gal batches. Would BG12 burners be sufficient?

Eventually, I plan to use 3 Bayou Classic 11gal stainless kettles. And I want this to be completed as inexpensively as possible.

This is what I have come up with so far. Do you think the stand will be stable and sturdy enough?

Your input is welcome and appreciated. Cheers!

The steel I acquired is 1x1 18 gauge and 1x1 11 gauge. The majority of it is 18 gauge. Based on my calculations, I will have to buy a few steel pieces to complete the project. Is the 18 gauge strong enough?

I want the stand to be 3 burner, using BG14 burners powered by standalone propane tank(s). Maybe BG12 burners if it is determined that they would be powerful enough for 5 gal batches. Would BG12 burners be sufficient?

Eventually, I plan to use 3 Bayou Classic 11gal stainless kettles. And I want this to be completed as inexpensively as possible.

This is what I have come up with so far. Do you think the stand will be stable and sturdy enough?

Your input is welcome and appreciated. Cheers!