haeffnkr

Well-Known Member

Hello,

I finally got my system up and running today.

It actually rained today and I was able to brew in my basement.

Needless to say, it was GREAT.

No more jet burners, no more fluctuating temps, no propane tanks to hall around, no more hauling all my stuff out of my basement to brew, then pack it all in again.

Need to thank PJ and all the nice folks on this forum for all the help provided and the nice folks at Auber.

I still need to hook up my exhaust fan, march pump and probably build another custom Inter Cooler but all that will get setup in time....

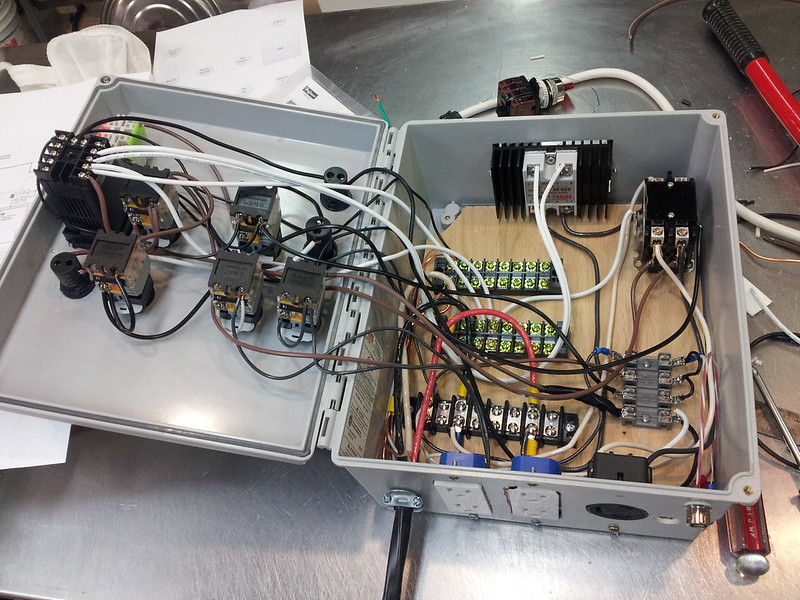

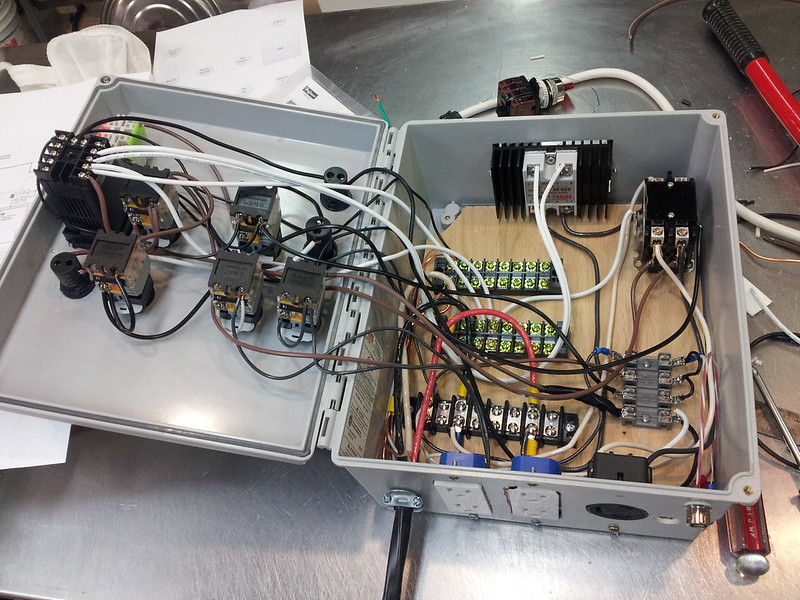

Not much to say about the system, standard Auber 2352 controller, I have a power light and a element light, lighted switches to turn on the controller, 2 outlets, the buzzer and the contactor.

Used an old reloading table for this project, it is not pretty but works well, with the legs cut short and casters put on it I can roll this around as needed.

My keg is kind of unique that I completely ground out the lip of the keg and have smooth sides, of course it is bottom drain which made clean up a breeze.

Hope this post and the pics help someone else in the future.

Let me know if there are any questions.

thanks Kevin

I finally got my system up and running today.

It actually rained today and I was able to brew in my basement.

Needless to say, it was GREAT.

No more jet burners, no more fluctuating temps, no propane tanks to hall around, no more hauling all my stuff out of my basement to brew, then pack it all in again.

Need to thank PJ and all the nice folks on this forum for all the help provided and the nice folks at Auber.

I still need to hook up my exhaust fan, march pump and probably build another custom Inter Cooler but all that will get setup in time....

Not much to say about the system, standard Auber 2352 controller, I have a power light and a element light, lighted switches to turn on the controller, 2 outlets, the buzzer and the contactor.

Used an old reloading table for this project, it is not pretty but works well, with the legs cut short and casters put on it I can roll this around as needed.

My keg is kind of unique that I completely ground out the lip of the keg and have smooth sides, of course it is bottom drain which made clean up a breeze.

Hope this post and the pics help someone else in the future.

Let me know if there are any questions.

thanks Kevin