Hi everyone

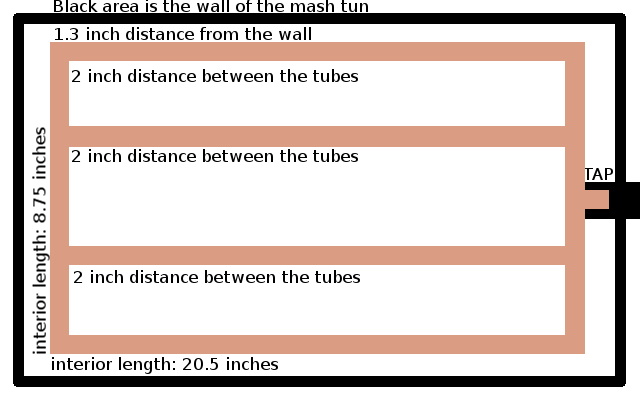

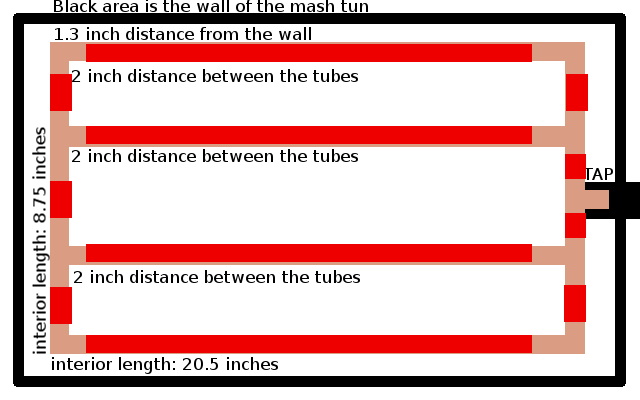

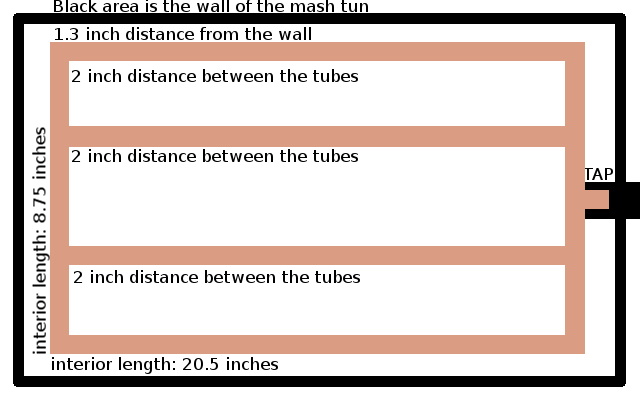

I live in Spain and apparently CPVC is not know here and I dont wanna use PVC for a manifold. So I have decided to use copper. I have created a design (a really simple one ) that you can find here as an attachment. The material seems to be available but I still have tons of questions.

) that you can find here as an attachment. The material seems to be available but I still have tons of questions.

The manifold will go into a 50 qt xtreme, coleman cooler.

Please advise me on these questions:

-what type of copper is good for such a manifold? Are there anything I should know about copper at this stage?

-is there a way to make it without welding, or anything extra? I'd like to buy copper T joints and just pust the parts together. Is that an option?

-the slits.....should only be cut on the 4 long tubes that run along the 20.5 inch wall? What should be the distance between the slits and how deep they should be cut into the tubes?

-do you guys think the 2-inch distance will do and help me achieve good efficiency? (I was told that a lot depends on the manifold when it comes to efficiency)

-I am wondering what diameter copper tubes I should buy...they dont really talk about those anywhere.

Thanks a lot.

UPDATE: do you guys think I could cut the ends of the elements and screw them together? Just as if they were screws. This is just an idea...it might be impossible....but I am trying to avoid soldering.

I live in Spain and apparently CPVC is not know here and I dont wanna use PVC for a manifold. So I have decided to use copper. I have created a design (a really simple one

The manifold will go into a 50 qt xtreme, coleman cooler.

Please advise me on these questions:

-what type of copper is good for such a manifold? Are there anything I should know about copper at this stage?

-is there a way to make it without welding, or anything extra? I'd like to buy copper T joints and just pust the parts together. Is that an option?

-the slits.....should only be cut on the 4 long tubes that run along the 20.5 inch wall? What should be the distance between the slits and how deep they should be cut into the tubes?

-do you guys think the 2-inch distance will do and help me achieve good efficiency? (I was told that a lot depends on the manifold when it comes to efficiency)

-I am wondering what diameter copper tubes I should buy...they dont really talk about those anywhere.

Thanks a lot.

UPDATE: do you guys think I could cut the ends of the elements and screw them together? Just as if they were screws. This is just an idea...it might be impossible....but I am trying to avoid soldering.