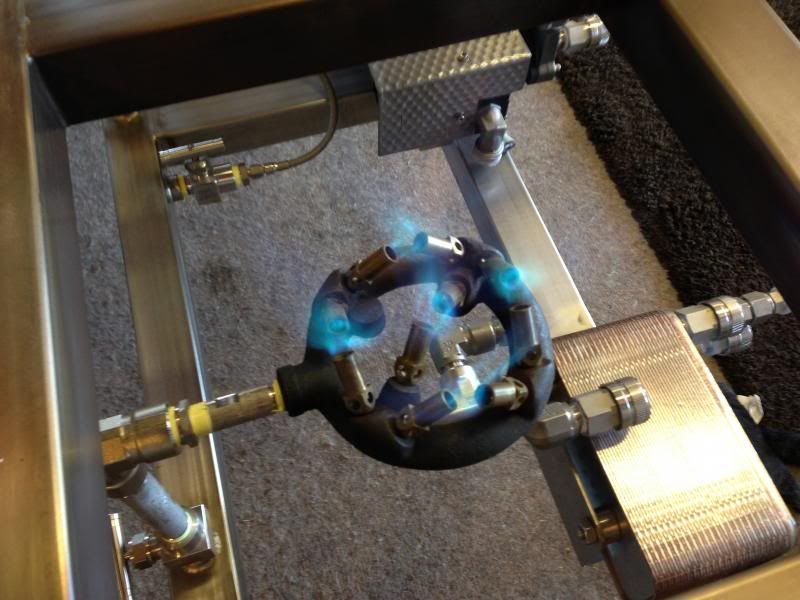

I bought burners from tejas. They get here Wednesday. I brewed 96 gallons in last two weeks with some irritations each day on burner performance. Step mashes not possible with 11 gal batches. Burners really susceptible to winds. When adapting my rig from the "shoppers choice" 10 jet mini burners to the low pressure banjo burners, I lost a lot of BTU power. I also have intermittent spark pilots. I didn't have new compression fittings for pilot burner tubing. I re used the old parts and they leaked. I tried my hardest to make it through the last brew session on Sunday but working on those connections ended up losing a burner that I couldn't get to fire. Long story. Ended up getting through a Belgian dubbel brew on two burners, but modified the planned step mash to a single infusion with a slow ramp up to mash out temps.. Tedious.

Anyway. This weekend, I am hoping to get my new burners plumbed in and tested and ready to rock and roll! What is the spacing from the tip of the brass jet to the bottom of the kettle again that you've been using?? Gonna try to keep my Marshall 300 series regulator, as it worked well with old mini jet burners before they leaked.

If that don't work ill go to an adjustable regulator with a dial gauge.

I am not going to enjoy re-plumbing my propane manifold and burners. Probably gonna need to totally disassemble and reassemble. Previously I used the steel flex hose to get from the valve outlet to the burner inlet. I had adjustable "stirrups" the burners rested on, those are gone now, and will need to hard plumb in the burners so getting height spacing will be crucial. I used permatex on pipe joints, s removing that will also be fun. Existing manifold is stainless steel pipe, so getting burners centered well is not gonna be a fun task.

I'll post results for sure, and ouch on those tejas prices. At least my initial shoppers choice burners worked great. With tejas I'm hoping to not have the same problems, but if I do I can swap them out if needed, looking forward to better performance.

TD